NAVAIR 01-1A-505-2

003 02

TO 00-25-255-1

Page 84

TM 1-1500-323-24-2

168. CRIMP REMOVABLE CONTACT CONNEC-

TOR REPAIR.

169. Connector repair includes contact removal where

necessary, to include wired, unwired, broken, power,

thermocouple, coaxial, twinax, and fiber optic, for

modification and system repair.

170. WIRED CONTACT REMOVAL. To remove

contacts assembled and crimped to wires, the following

procedure applies:

a. Remove backshell and accessories in

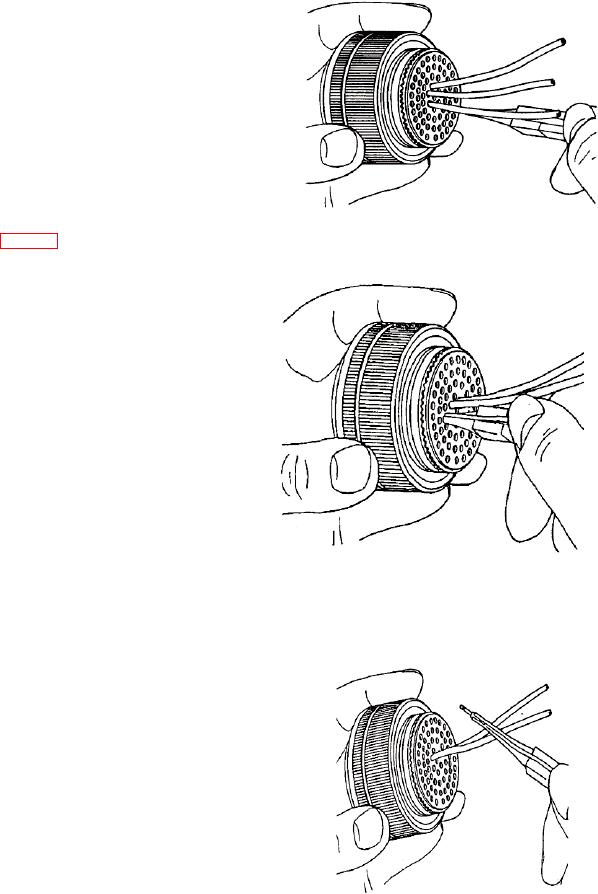

Figure 36. Removal Tool Insertion

accordance with WP 003 03.

b. Select proper removal tools by referring to

Table by Series (Figure 29).

c.

Using the white tip of removal tool per contact

size, hold at right angle to grommet face centered over

contact being removed and push wire into groove of

tool (Figure 36). For smaller diameter wires, be careful

the tool does not collapse around the wire when

inserted and cause the tool tip to hit the contact crimp

barrel instead of sliding over it. A collapsing tool can

also damage grommet sealing wafers.

d. Slide end of removal tool over contact and

push into insert hole until retention clip is fully opened

(Figure 37).

e.

Grasp wire and removal tool and pull contact

Figure 37. Unlocking Retention Clip

from rear of connector (Figure 38).

f.

A cross sectional view of contact removal is

shown which repeats the above steps (Figure 39).

171. UNWIRED CONTACT REMOVAL. Unwired

contacts are inserted to complete the connector

configuration and to maintain mating integrity as well

as environment resistance.

a. Select proper tool as specified in the Tables by

Series (Figure 40).

b. Depress plunger, hold tool at right angle to

grommet face and push into hole of contact to be

removed until bottomed and contact is released.

c.

Remove contact from connector by pulling

both plunger and probe straight back.

Figure 38. Contact Removal

d. Eject contact from unwired contact removal

tool by pressing plunger.