TM 1-1510-262-10

system when the detector (sensing tubing) senses an over temperature condition in critical areas around the en-

gine. The detector is dual functioning and responds to overall "average" temperature, or a highly localized "discrete"

temperature, caused by lames or hot gases. Both the average and discrete temperatures are preset, and cannot

be adjusted in the ield. The sensor tubing consists of an outer tube illed with an inert gas, and an inner hybrid

core that is illed with an active gas. The gases within the tube form a pressure barrier that keeps the contacts of

the responder integrity switch closed for ire alarm continuity test functions. As the temperature around the sensing

cable increases, the gases within the tube begin to expand. When the pressure from the expanding gases reaches

a preset point the contacts of the responder alarm switch close activating the respective ire warning system.

b. Warning System. The ire warning system consists of two lenses, placarded #1 FIRE PULL and #2 FIRE

PULL located in the T handles below the glareshield, two MASTER WARNING annunciators located in opposite

sides of the glareshield, and two responder units with sensors in the engine compartments. If the detector should

develop a leak, the loss of gas pressure would allow the integrity switch to open and signal a lack of detector integrity.

c. Testing. Two switches located on the copilot s left subpanel accomplish testing system integrity, availability

of power, and the annunciators, (#1 and #2 FIRE PULL and MASTER WARNING ). The switches are placarded

ENG FIRE TEST , DET -OFF -EXT , LEFT , and RIGHT . When either (LEFT or RIGHT ) switch is placed in the

DET position, electrical current lows from a 5-ampere circuit breaker placarded FIRE DETR located on the over-

head circuit breaker panel, through the engine ire detector circuitry to the integrity switch contacts in the respective

responder unit, causing the respective annunciators to illuminate. If the circuit breaker opens, the system will not

operate during a test, or activate the annunciators if the detector cable senses an over temperature condition. The

system may be tested before, after, or in light as desired.

2-26. ENGINE FIRE EXTINGUISHER SYSTEM.

a. Description. The engine ire extinguisher system is comprised of a supply cylinder, explosive squib, and

valve located in each of the main gear wheel wells (Fig. 2-21). A gauge calibrated in PSI is provided on each supply

cylinder for determining the level of charge. The extinguishing agent charge level should be checked during each

prelight. When ired, the explosive squib opens the valve, releasing the entire pressurized extinguishing agent into

a plumbing network. The plumbing network terminates in spray nozzles, strategically located in the probable ire

areas of the engine compartment, which distribute the extinguishing agent.

b. Operation. Fire control T handles used to arm the extinguisher system are centrally located in the instrument

panel, immediately below the glareshield. These controls receive power from the hot battery bus. The ire detec-

tor system will indicate an engine ire by illuminating the MASTER WARNING annunciators on the glareshield and

the respective #1 or #2 FIRE PULL annunciators in the ire control T handles. Pulling the ire control T handle will

electrically arm the extinguisher system and close the irewall shutoff valve for that particular engine. This will cause

the annunciator in the PUSH TO EXTINGUISH switch and the respective #1 and #2 FUEL PRESS annunciators in

the warning annunciator panel to illuminate. Pressing the lens of the PUSH TO EXTINGUISH ire switch will ire the

squib, expelling the entire agent in the cylinder at one time. A hinged plastic guard covers the PUSH TO EXTIN-

GUISH ire switch to prevent inadvertently actuating the ire extinguish switch squib circuit. The respective caution

annunciator, #1 and #2 EXTGH DISCH on the caution/advisory annunciator panel and the MASTER CAUTION an-

nunciator on the glareshield will illuminate and remain illuminated, regardless of the master switch position, until the

squib is replaced.

c. Testing. The test switches located in the copilot s left subpanel, are placarded ENG FIRE TEST , DET - OFF

- EXT , LEFT , and RIGHT , and provide a test of the ire detection and extinguisher circuitry. When either of the

switches is placed in the EXT position, the corresponding PUSH TO EXTINGUISH , SQUIB OK , and EXTGH DISCH

annunciators should illuminate. The system may be tested before, after, or in light as desired. A gauge calibrated

in PSI is mounted on each extinguishing agent supply cylinder for determining the level of charge and should be

checked during prelight (Table 2-1).

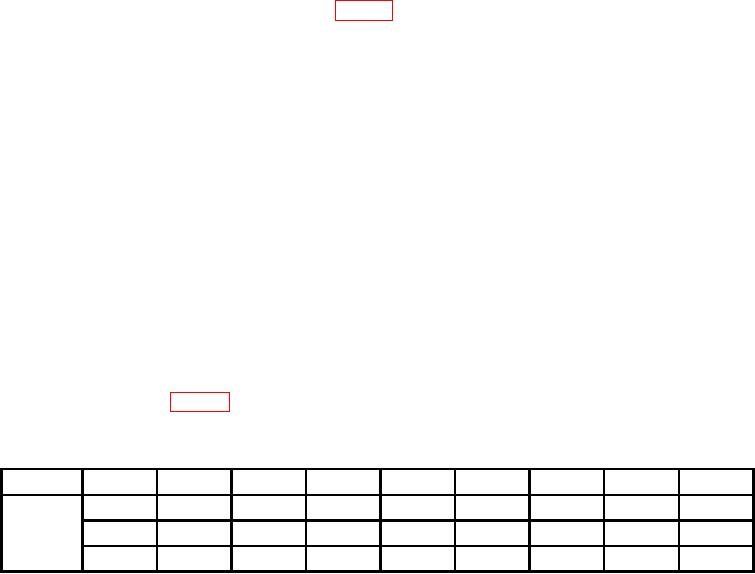

Table 2-1.

Engine Fire Extinguisher Gauge Pressure

-40

-29

-18

-06

04

16

27

38

48

TEMP C

109

220

250

290

340

390

455

525

605

to

to

to

to

to

to

to

to

to

PSI

240

275

315

365

420

480

550

635

730

2-31