TM 10-4930-351-14

0094 00

INSTALLATION

1.

Lubricate lightly and install O-ring (19) in vane pump housing (20).

2.

Lubricate lightly and install O-ring (15) on shaft.

3.

Lubricate stationary seal (11) and push into shaft seal housing (4) so that elastomer portion seats against housing.

4.

Install rotating spring (13) on spacer (14), and install on shaft so that lipped portion of seal faces out (to interface with

stationary seal installed in previous step).

5.

Apply anti-seize compound to the five shaft seal housing screws (9). Place shaft seal housing (4) over shaft with weep

hole facing down and mounting holes aligned, hold housing down against spring pressure, and install the five seal

housing screws (9) and flat washers (10) that secure shaft seal housing (4) to vane pump housing (20).

6.

Rotate shaft by hand to check freedom of rotation. Some rubbing at the inlet is normal but if the shaft binds or will not

turn, remove shaft seal housing (4) and check rotating shaft seal (12) for proper assembly.

7.

Install washer (8) and shaft nut (7) on shaft hand tight.

8.

Install splined flexible coupling adapter (5) on pump shaft. Tighten set screw against shaft key (6).

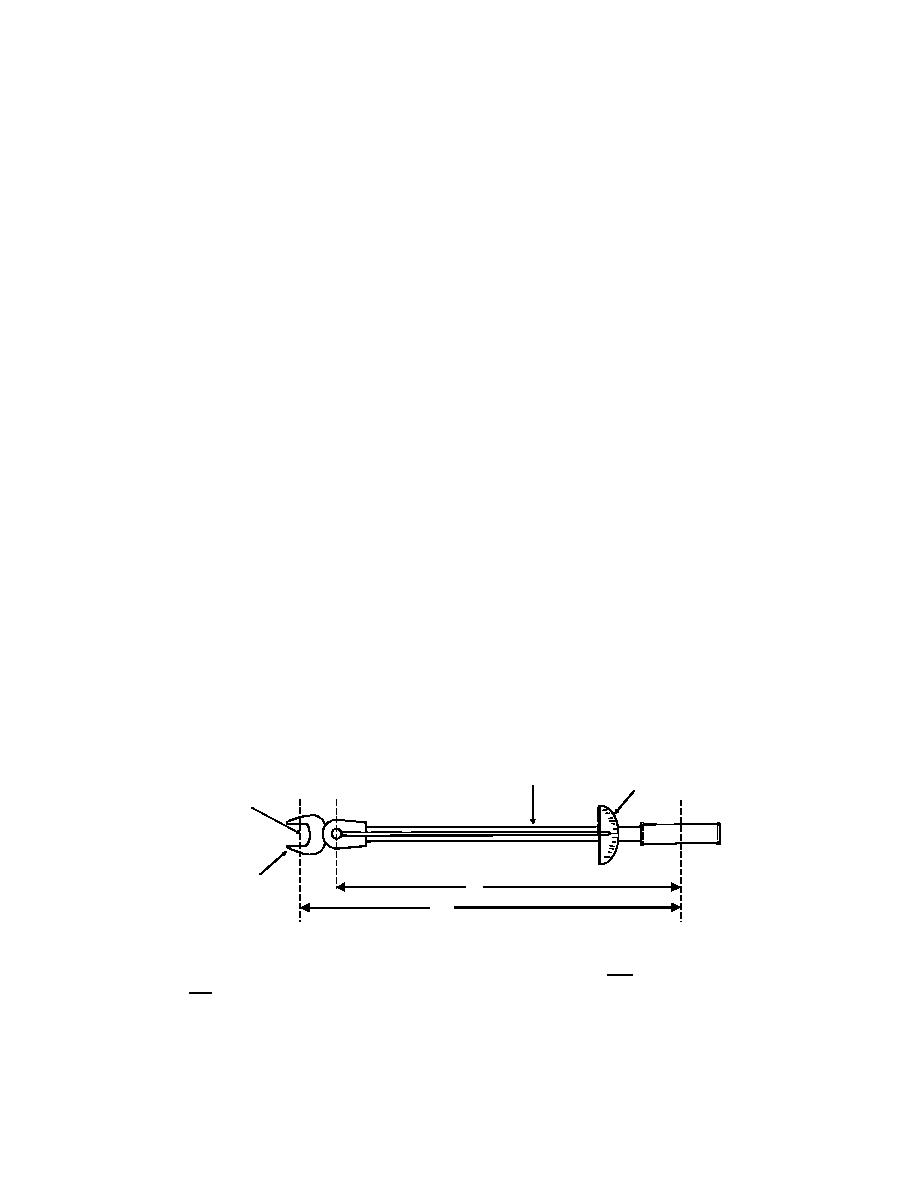

NOTE

The shaft nut must be torqued to a specific value to provide the proper tension on the

rotating shaft seal. However, a standard socket on a torque wrench cannot be used. A

crow foot adapter, as shown in the illustration below, will allow access to the nut but

adding the adapter will also cause the torque reading on the wrench to be different from

the actual torque applied to the nut. To calculate the torque value to be indicated when

the required torque is known, perform the following procedure:

a.

Measure the distance L1 on the torque wrench to be used.

b.

Install the crow foot adapter and measure the distance L2.

c.

Divide L2 into L1.

d.

Multiply the quotient by the torque specified for the nut. The product is the torque

value that will be indicated on the wrench when the specified torque has been

reached on the nut.

TORQUE

TINDICATED

WRENCH

T

SPECIFIED

CROW FOOT

L1

ADAPTER

L2

For example: The specified torque value for the shaft nut is 100-110 ft lb (135-149

Nm). The distance L1 measured on your torque wrench is 19 inches. The distance L2

measured on your torque wrench is 21 inches. In the following formula, TINDICATED

is the value you should read on your torque wrench with the crow foot adapter installed.

TSPECIFIED is the torque value specified for the nut.

0094 00-3