TM 10-4930-351-14

0095 00

6

5

4

3

8

7

2

1

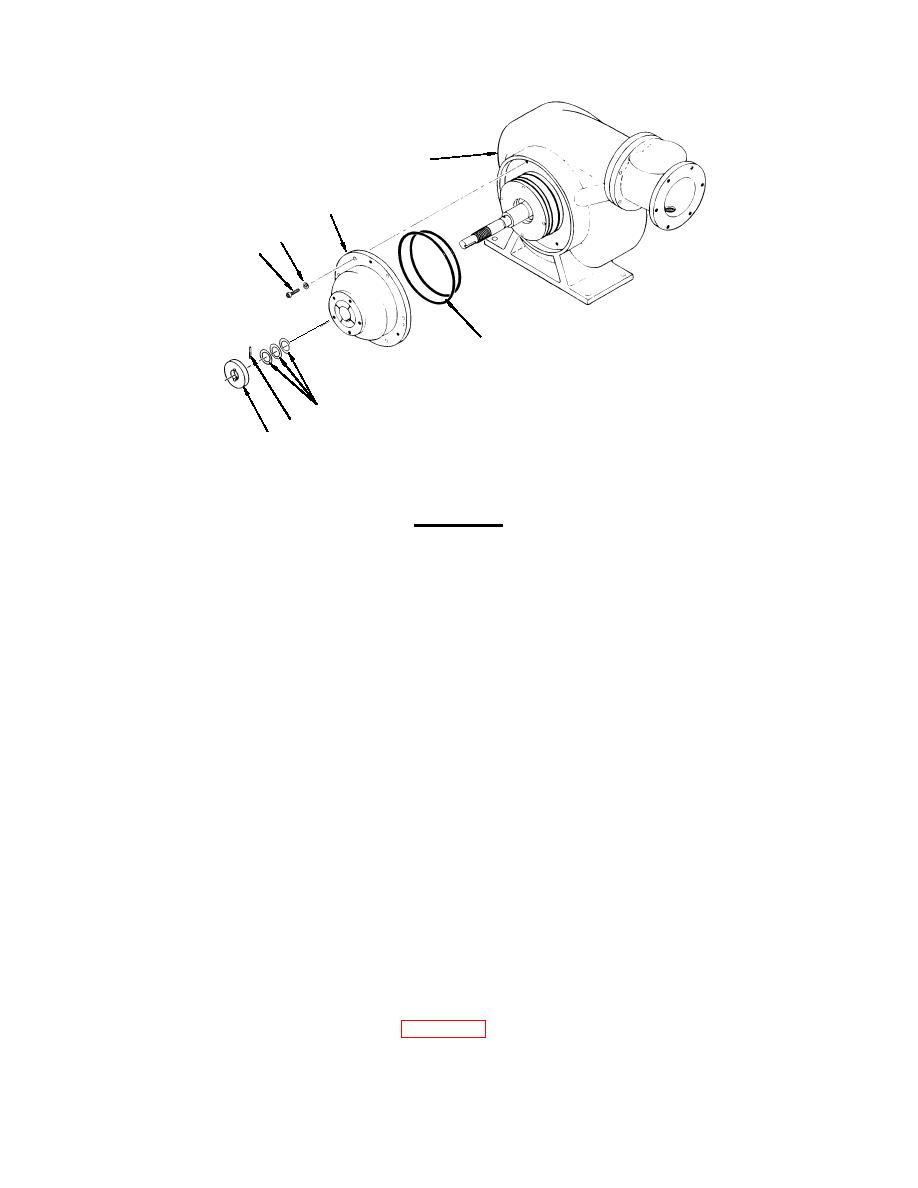

INSTALLATION

CAUTION

Ensure inlet is installed before commencing this procedure. Inlet installation will prevent the thrust

washer dowel falling out of place. Equipment damage will occur if pump is run with a loose dowel.

Ensure all paint and debris have been removed from area of vane pump housing seat. Any debris

will cause vane pump housing to be misaligned and equipment damage will result.

1.

Lightly lubricate O-rings (8) with petrolatum and install in O-ring grooves on vane pump housing (5). Do not allow the

O-rings to twist or roll during installation.

2.

Install vane pump housing (5).

a.

Hold vane pump housing (5) over shaft so that mounting holes and guide pin holes are aligned, and install three 1/4-

28 x 1-1/2 jack bolts through housing into mounting holes. Space the bolts approximately equal distances apart and

tighten finger tight. Using the bolts as guides, push the vane pump housing onto the shaft. Remove the three jack

bolts.

b.

Apply anti-seize compound to and install the six socket head screws (3) and flat washers (4) to secure the vane

pump housing (5) to the impeller housing (6). Alternately tighten screw pairs to draw housing down evenly. Rotate

shaft by hand after each tightening sequence to ensure binding has not occurred. When all six screws are finger

tight, repeat pattern to secure tightly. Verify proper alignment by rotating shaft by hand. Shaft will rotate freely

without binding when all screws are tightened evenly.

3.

Install shims (7) on shaft.

4.

Install thrust washer (1).

a.

Install dowel pin (2) in shaft.

b.

Install thrust washer (1) so that dowel pin (2) engages slots in washer.

5.

Install shaft seal assembly and shaft nut. Refer to WP 0094 00.

END OF WORK PACKAGE

0095 00-2