TM 55-2840-241-23

Change 19 7-5

d.

Insect for nicks, dents, and erosion on the blade

leading and trailing edges and at the blade tip. All dam-

age and imperfections must be blended out. (Refer to

paragraph 7-24 a and b.) Blended leading and trailing

edges, and chamfered blade tips must not exceed the

limits shown on figures 7-10 and 7-11.

e.

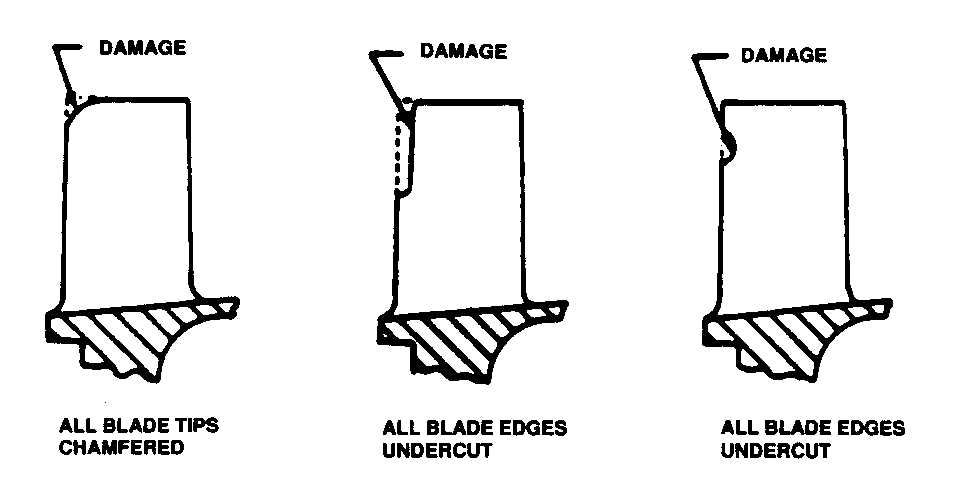

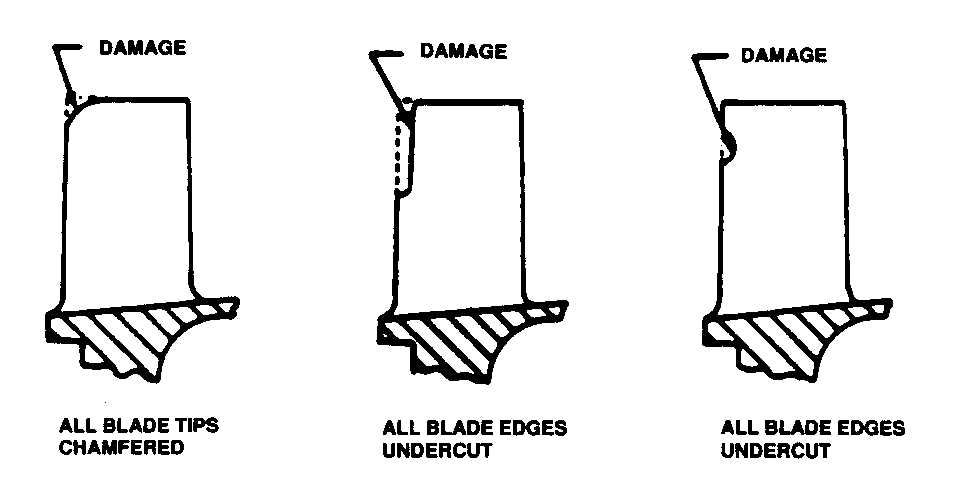

Inspect the blade tips and leading edges for evi-

dence of loose plastic rub on all blades in a given stage.

Loose plastic rub is a result of the compressor case plas-

tic lining coming loose, and displacing inward, wearing

away portions of all blades in a given stage. Loose plastic

rub is evidenced as a chamfer at the leading edge tip or

an undercut of the blade leading edge. (See figure, 7-2.)

Replace the engine if rub is indicated.

f.

Inspect the blade tips for heat discoloration on one

or more blades. Heat discoloration is caused by severe

blade rub on the compressor case plastic lining which

occurs when the wheels shift off center due to an unbal-

ance condition. Replace the engine if heat discoloration

is detected.

7-10. Compressor Stator Vane Inspection.

Visually inspect the compressor stator vanes for the

following conditions. Replace both compressor case

halves if any of the limits are exceeded.

NOTE

This inspection requires removal of a com-

pressor case half and shall be performed only

for the reasons stated in paragraph 6-2.

a.

Inspect for cracked or missing stator vanes -

none are permitted. If cracks are suspected in the stator

vanes, refer to TM 1-1520-254-23, Technical Manual Avi-

ation Unit Maintenance (AVUM) and Aviation Intermedi-

ate Maintenance (AVIM) Manual Nondestructive Inspec-

tion Procedure for OH-58 Helicopter Series.

b.

Inspect the vane tips for evidence of rub. Rub is

indicated by smeared metal on the vane tip associated

with a burr on the convex side or by heat discoloration on

the vane. Replace the engine if rub is indicated.

c.

Insect for evidence of corrosion on the vanes.

Pitting in any area of the vane that forms a definite line

is not acceptable. Replace the compressor case if pitting

exceeds blend limits. (Refer to paragraph 7-25 a.)

d.

Inspect for erosion on the airfoil leading and trail-

ing edges. Replace the compressor case if the limits of

figure 7-3 are exceeded.

e.

Inspect for nicks, and dents on the vane and trail-

ing edges. All damage and imperfections must be

blended out. (Refer to paragraph 7-25 a.) Blended lead-

ing and trailing edges must not exceed the limits shown

on figure 7-13.

f.

Insect for nicks and dents on the vane airfoil sur-

face. All damage and imperfections must be blended out.

Refer to paragraph 7-25 a.) Blended areas must be with-

in the limits shown on figure 7-13.

g.

Inspect for bent vanes. Straighten vanes that are

bent on the inner three-fourths of the vane. Vanes that

are bent on the outer one-fourth are not acceptable.

7-11. Compressor Plastic Coating Inspection.

Visually inspect the compressor case plastic coating

for the following conditions. Replace both compressor

case halves if any of the limits are exceeded.

Figure 7-2. Compressor Blade Damage Caused by Rub