TM 55-2840-241-23

7-6 Change 19

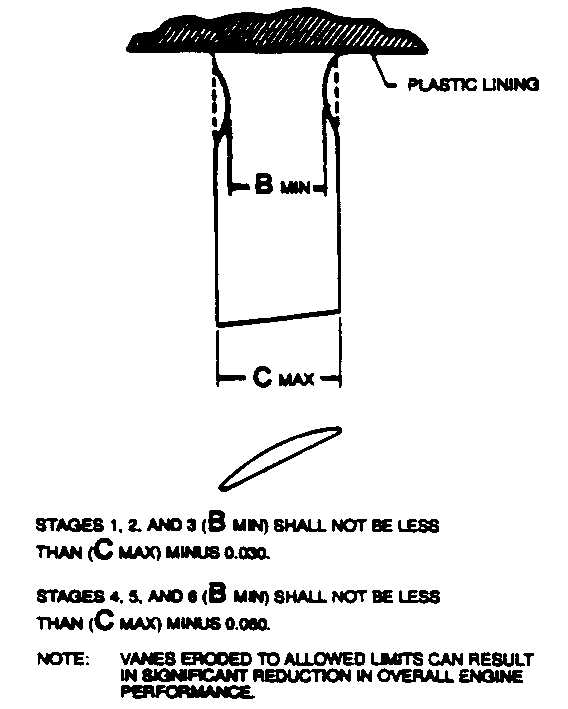

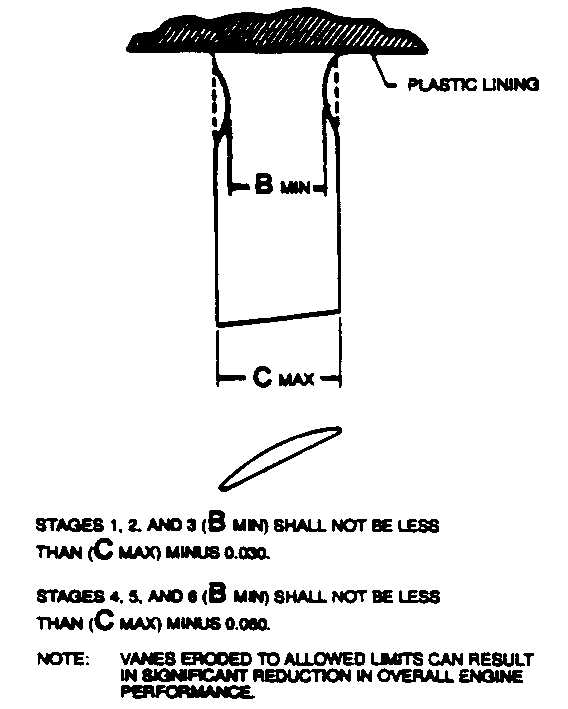

Figure 7-3. Compressor Vane Erosion

NOTE

This inspection requires removal of a com-

pressor case half and shall be performed only

for the reasons stated in paragraph 6-2.

a.

Cracks are acceptable without limitation as to

length and quantity provided the plastic is securely

bonded to the case, except cracks along the horizontal

splitline in excess of 1/2 inch are unacceptable.

b.

Debonded, missing, or loose plastic in the vane

row areas only is acceptable provided that no more than

50 percent in stages 5 and 6 or 25 percent in stages 1

through 4 are missing. Any raised or loose plastic in the

vane row areas shall be removed.

c.

Raised or debonded plastic in the blade path

areas as not acceptable. Circumferential cracks at the

front or rear of the blade path can cause an arc segment

of the plastic to raise when at normal operating tempera-

tures and cause plastic wear in line with the leading or

trailing edge or the blade tips. A groove worn in the plastic

adjacent to a circumferential crack is evidence of de-

bonding in the blade path.

d.

Erosion of the plastic coating is acceptable un-

less bare metal in the lower half is exposed.

7-12. Compressor Front Support Inspection.

Visually inspect the compressor front support. Re-

place the engine if any of the following conditions are

found.

a.

Any cracks in the parent metal or braze joints. If

cracks are suspected, refer to TM 1-1520-254-23, Tech-

nical Manual Aviation Unit Maintenance (AVUM) and Avi-

ation Intermediate Maintenance (AVIM) Manual Nonde-

structive Inspection Procedure for OH-58 Helicopter

Series.

b.

Gradual dents exceeding 1/16 in. deep, or acute

dents exceeding 1/32 in. deep. No punctures allowed.

c.

Weld failures at the trailing edge spacers, as

viewed from the rear with the compressor case half re-

moved.

d.

Vane erosion to the extent that reduction of skin

thickness is apparent and/or trailing edge slots are re-

stricted.

e.

Bullet nose dents with nicks or scratches on

dome over 0.020 in. deep after stone blending and fine

abrasive paper polishing.

7-13. Diffuser Scroll Inspection.

Visually inspect the installed diffuser scroll for the

following conditions. Replace the engine if the damage

cannot be repaired.

a.

Inspect for visible cracks. Replace the engine if

cracks are found. If cracks are suspected, refer to TM

1-1520-254-23, Technical Manual Aviation Unit Mainte-

nance (AVUM) and Aviation Intermediate Maintenance

(AVIM) Manual Nondestructive Inspection Procedure for

OH-58 Helicopter Series.

NOTE

The turning vanes and air tube inserts may be

inspected only when the combustion section

is removed.

b.

Check the turning vanes in the outlet ports for

evidence of damage. Damage is indicative of impeller

vane up or shroud failure. Replace the engine.

c.

Inspect the diffuser scroll discharge air tube in-

serts for wear and looseness. If wear in the ID of the

insert exceeds 0.010 in. depth or there is evidence that

the insert has been pulled out of the scroll, replace the

engine.

7-13.1 Diffuser Vent Tube.

Visually inspect for cracks, bends, and dents. No

cracks, dents or bends are permitted. Replace vent tube.

If cracks in vent tube are suspected, refer to TM

1-1520-254-23, Technical Manual Aviation Unit Mainte-

nance (AVUM) and Aviation Intermediate Maintenance

(AVIM) Manual Nondestructive Inspection Procedure for

OH-58 Helicopter Series.

Inspect the tube for movement. None is permitted.

Remove and replace tube.

7-14. Gearbox Inspection.

Visually inspect the exterior of the gearbox for the

following conditions.

a.

Check for cracks in the gearbox housing and cov-

er, especially in stress areas; engine mounts, accessory

pads, and at the splitline. If cracks are found, replace the

engine. If cracks in gearbox housing or cover are sus-

pected, refer to TM 1-1520-254-23, Technical Manual

Aviation Unit Maintenance (AVUM) and Aviation Inter-

mediate Maintenance (AVIM) Manual Nondestructive In-

spection Procedure for OH-58 Helicopter Series.

b.

Check for oil leaks. If area below seal at any

accessory or power takeoff pad (figure 7-4) is dripping,

replace the, seal assembly. (Refer to paragraph 7-27.)