TM 55-2840-241-23

Change 19 7-7

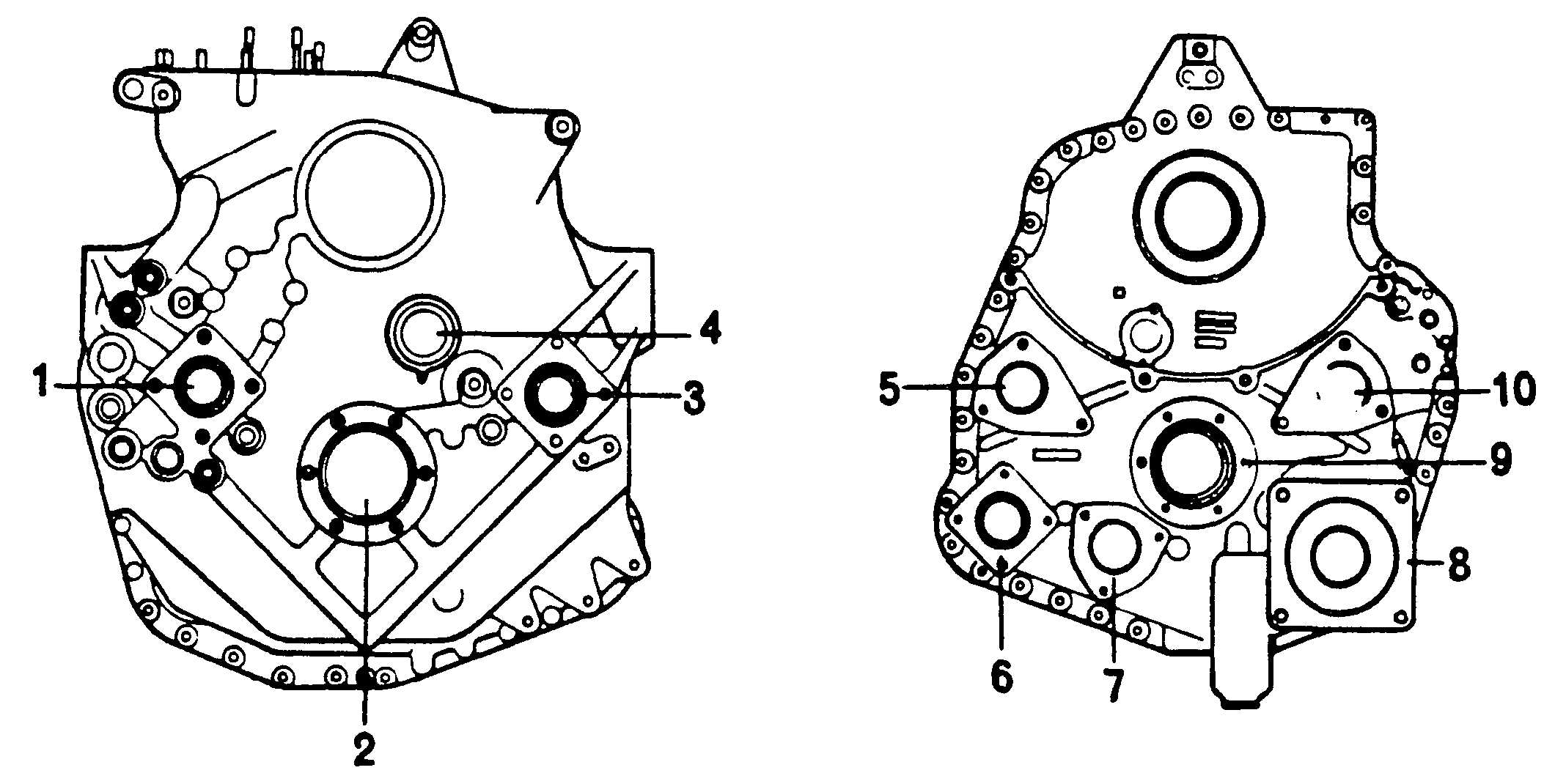

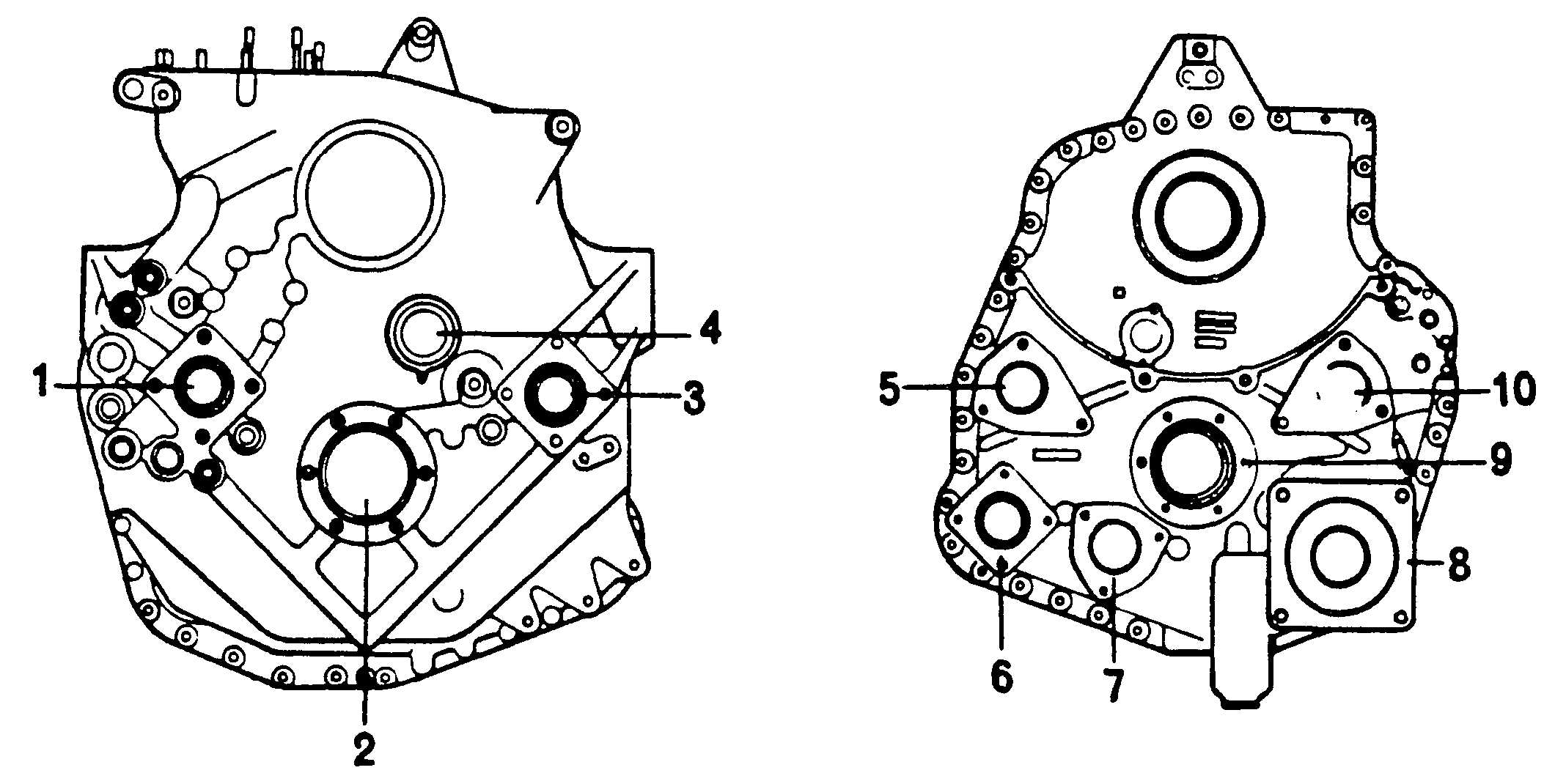

1213/1214

1.

Gas producer tachometer-

4.

Torquemeter spanner nut

9.

Power takeoff

generator

5.

Power turbine fuel govenor

10.

Gas producer fuel control

2.

Power takeoff

6.

Spare (not used)

3.

Power turbine tachometer

7.

Fuel pump generator

generator

8.

Starter-generator

Figure 7-4. Gearbox Accessory Pad Locations

c.

If any gearbox-mounted accessory is removed,

visually inspect the gearbox studs for security, worn

areas, and damaged threads. Replace loose, damaged,

or worn studs. (Refer to paragraph 7-28.)

d.

Check for damaged paint surfaces. Repair dam-

aged paint per paragraph 7-29.

7-15. Thermocouple Assembly Inspection.

When erroneous indications are suspected, ensure

that the indicating system is functioning properly. Per-

form a TOT gage calibration check and a total TOT circuit

resistance check. (Refer to TM 55-4920-244-14 and TM

55-1520-228-23.) If no discrepancies are noted, check

the thermocouple system as follows. Do not remove the

thermocouple assembly from the engine.

a.

Visually inspect the thermocouple assembly for

broken leads, loose terminals, and other visible damage.

b.

Disconnect the leads from the terminal assembly

mounted on the right-hand side of the exhaust collector.

c.

Check the internal resistance of the thermocou-

ple harness at the terminal block on the right-hand side

of the exhaust collector. Resistance shall be 0.55 to 0.65

ohms.

d.

Reconnect the leads to the terminal assembly.

7-16. Exhaust Collector Support Inspection.

Visually inspect the exhaust collector support for

cracks. Cracks are not repairable, replace the engine. If

cracks in the exhaust collector are suspected, refer to TM

1-1520-254-23, Technical Manual Aviation Unit Mainte-

nance (AVUM) and Aviation Intermediate Maintenance

(AVIM) Manual Nondestructive Inspection Procedure for

OH-58 Helicopter Series.

7-17. Outer Combustion Case Inspection.

Visually inspect for cracks and dents in sheet metal

surfaces and wear in the air tube bosses. Replace the

outer combustion case if the repairable limits are exceed-

ed. If cracks on sheet metal surface are suspected, refer

to TM 1-1520-254-23, Technical Manual Aviation Unit

Maintenance (AVUM) and Aviation Intermediate Mainte-

nance (AVIM) Manual Nondestructive Inspection Proce-

dure for OH-58 Helicopter Series.

a.

Check for cracks in the outer shell. Replace the

outer combustion case if nonrepairable cracks are found.

(See figure 7-5.) Weld all repairable cracks. (Refer to

paragraph 7-30.) If cracks in outer shell are suspected,

refer to TM 1-1520-254-23, Technical Manual Aviation

Unit Maintenance (AVUM) and Aviation Intermediate

Maintenance (AVIM) Manual Nondestructive Inspection

Procedure for OH-58 Helicopter Series.

b.

Check for cracks in the liner (inner basket). Weld

repair cracks three inches or less in length and a mini-

mum of one inch apart. (Refer to paragraph 7-30.) Re-

place the outer combustion case if cracks are greater

than three inches in length, cracks are less than one inch

apart, or there are more than two cracks.

c.

Check for dents in the outer shell. Replace the

outer combustion case if dents are more than 1/8 in.

deep. (See figure 7-6.)

d.

Check for wear in the air tube bosses. Replace

the outer combustion case if wear is greater than 0.004

in. deep or out of round more than 0.004 in. (measure

from adjacent unworn area.) (See figure 7-7.)