TM55-2840-251-23

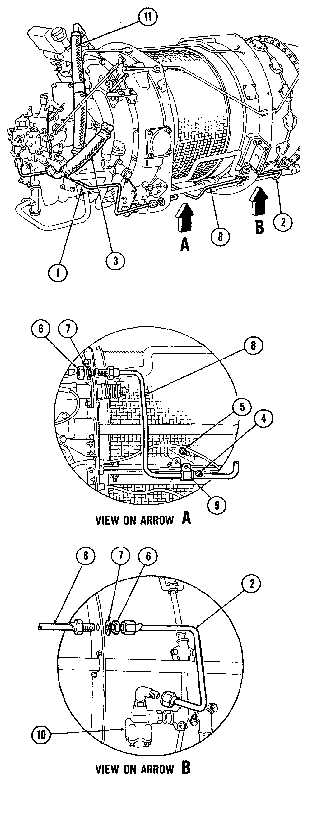

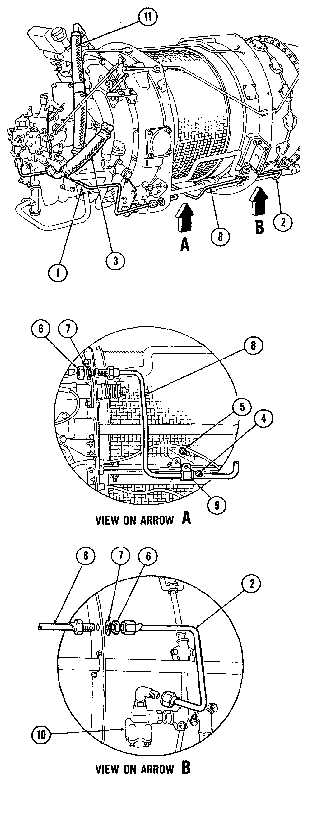

6-11 FUEL LINES AND FITTINGS (Continued)

6-11-4 INSTALLATION

1.

Install rigid tube (8) through center and rear fireseals

and temporarily secure with washers (7) and nuts (6).

2.

Install loop clamp (9) on tube assembly (8) and

secure to bracket on air inlet screen flange with bolt (5)

and self-locking nut (4). Torque nut to 36 to 40 inch-

pounds.

3.

Torque nuts (6) to 65 to 75 inch-pounds. Do not

lockwire at this stage.

4.

Install rigid tube (2) on fuel dump valve (10) elbow

and on tube (8) at center fireseal. Check torque locknut

on dump valve elbow to 38 to 42 inch-pounds, torque

tube (2) connections to 30 to 100 inch-pounds and

lockwire (E.5) to locknut on elbow and to nut (6).

5.

Install rigid tube on fuel control unit and on tube (8)

at rear fireseal. Torque connections to 90 to 100 inch-

pounds and lockwire (E.5) to nut (6) and fuel control

elbow.

6.

Install flexible tube (3) on fuel pump adapter and on

fuel control unit elbow. Torque connections to 270 to

300 inch-pounds and lockwire (E.5).

7.

Install flexible tube (11) on fuel pump and oil-to-fuel

heater elbow. Torque connections to 450 to 500 inch-

pounds and lockwire (E.5).

8. Inspect.

FOLLOW ON MAINTENANCE:

None

END OF TASK

6-52