TM 55–2840–254–23

2–46 Change 7

END OF TASK

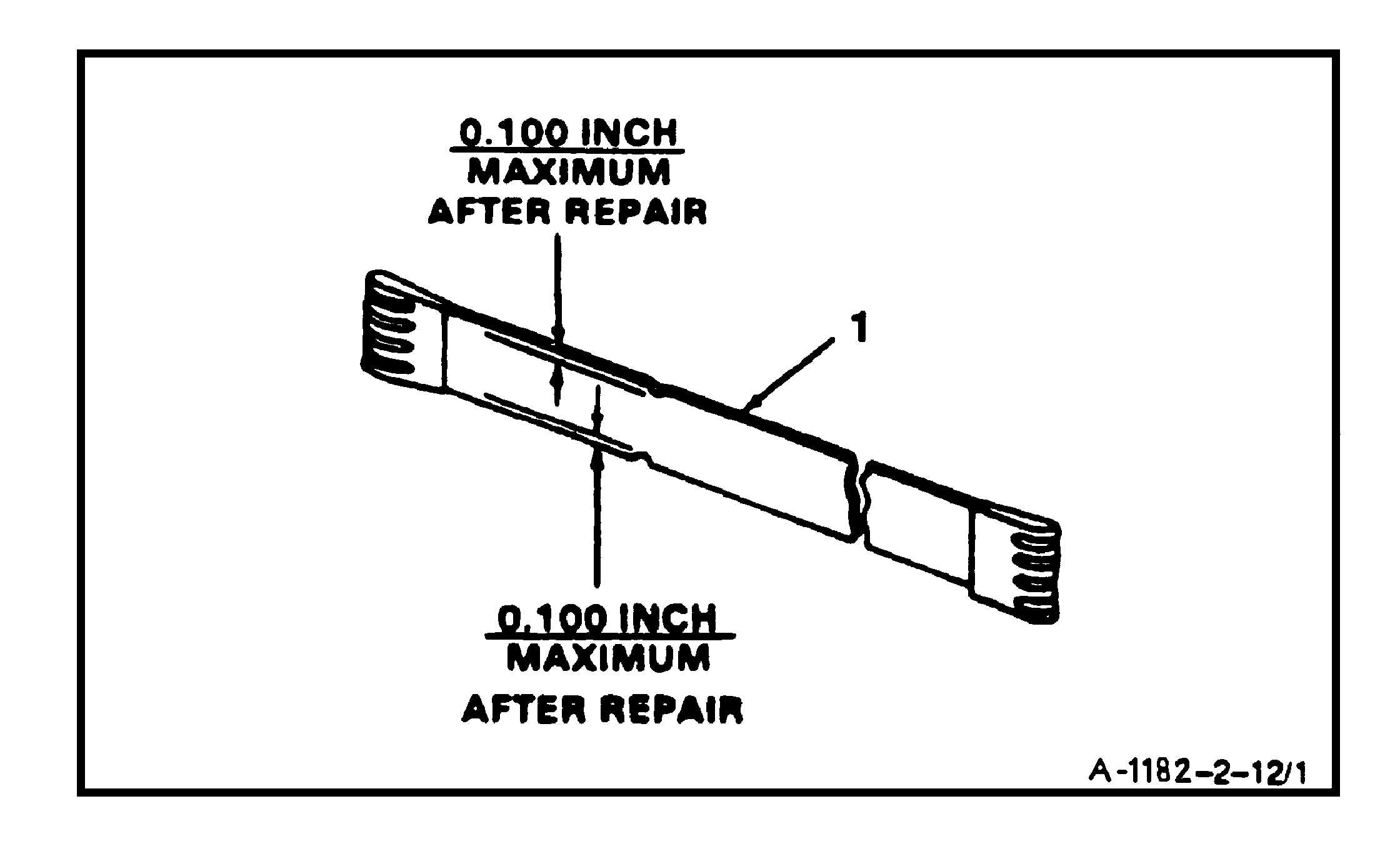

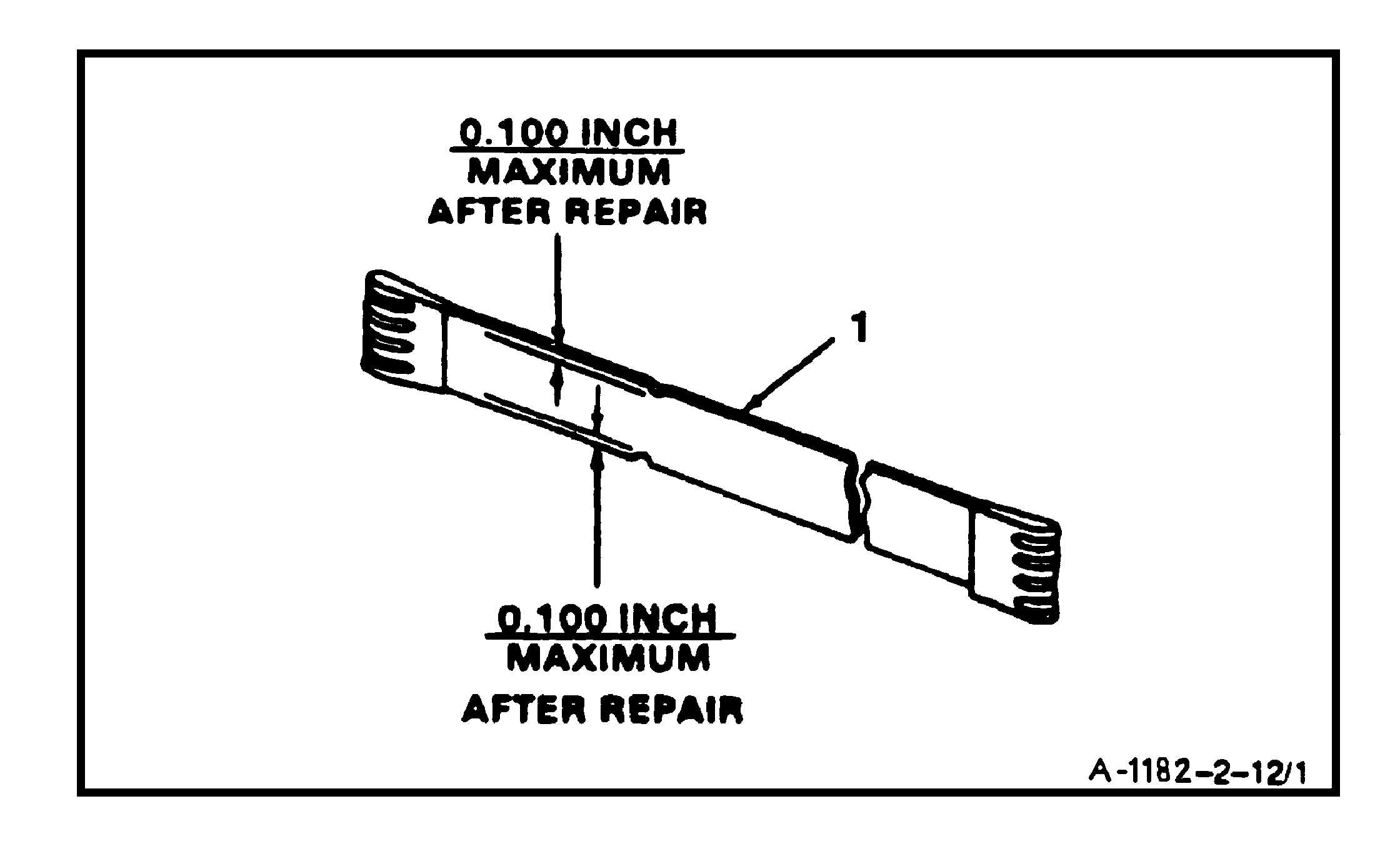

2–12 REPAIR COMPRESSOR BLEED BAND

2–12

INITIAL SETUP

Applicable Configurations:

All

Tools:

Technical Inspection Tool Kit.

NSN 5180–00–323–5114

Hand File Set

Materials/Parts:

Carborundum Stone (E 11)

Crocus Cloth (E16)

Perchloroethylene (E–68)

Isopropyl Alcohol (E–69)

Fluorescent–Penetrant Materials (E73),

Appendix C

Personnel Required:

68B10 Aircraft Powerplant Repairer

68B30 Aircraft Powerplant Inspector

References:

TM 1–1500–335–23

Equipment Condition:

Off Engine Task

CAUTION

The bleed band is very thin and bends

easily. Be careful not to kink or bend it

during handling. If kinked or bent,

bleed band must be replaced.

1. Repair edge wear up to 0.100 inch deep, on

bleed band (1) as follows:

NOTE

Repair is allowed only if depth after repair

is not more than 0.100 inch.

a.

Blend–repair to a smooth contour using

carborundum stone (E11).

b.

Remove burrs around repair from both

sides of band. Use file.

c.

Final polish area with crocus cloth (E16).

d.

Fluorescent–penetrant Inspect per para-

graph 2–12.1.3, repaired area (Ref. TM

1–1500–335–23).

e.

Parts requiring fluorescent penetrant in-

spection shall be cleaned using perchloroe-

thylene (item E–68, appendix C) to remove

surface contamination. Parts must be visi-

bly dry prior to application of penetrant. To

facilitate drying, parts may be wiped with

isopropyl alcohol (item E–69, appendix C)

or dried with air circulation at 130 F for a

minimum of five minutes.

INSPECT

FOLLOW–ON MAINTENANCE

None