TM 55-4920-328-13

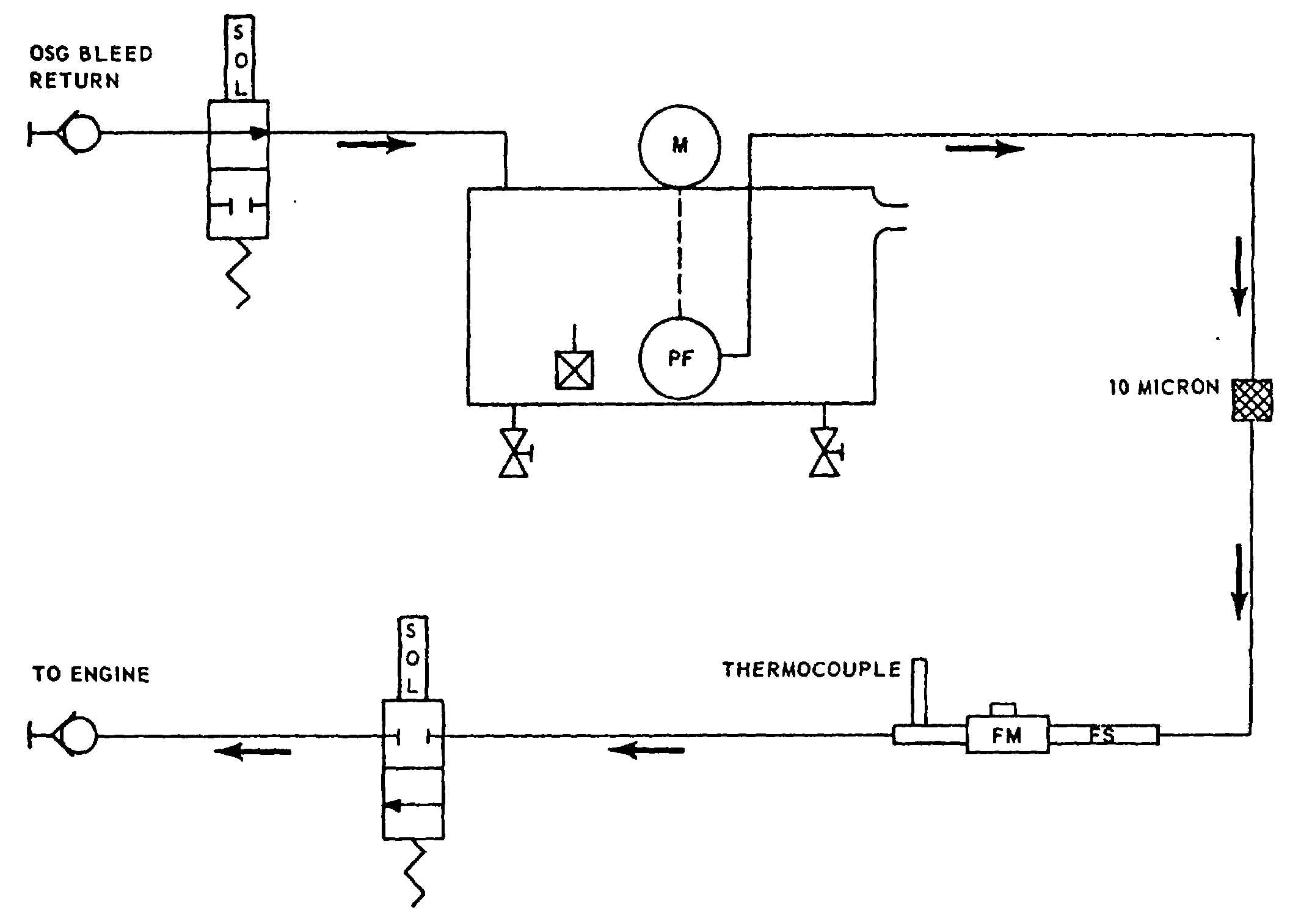

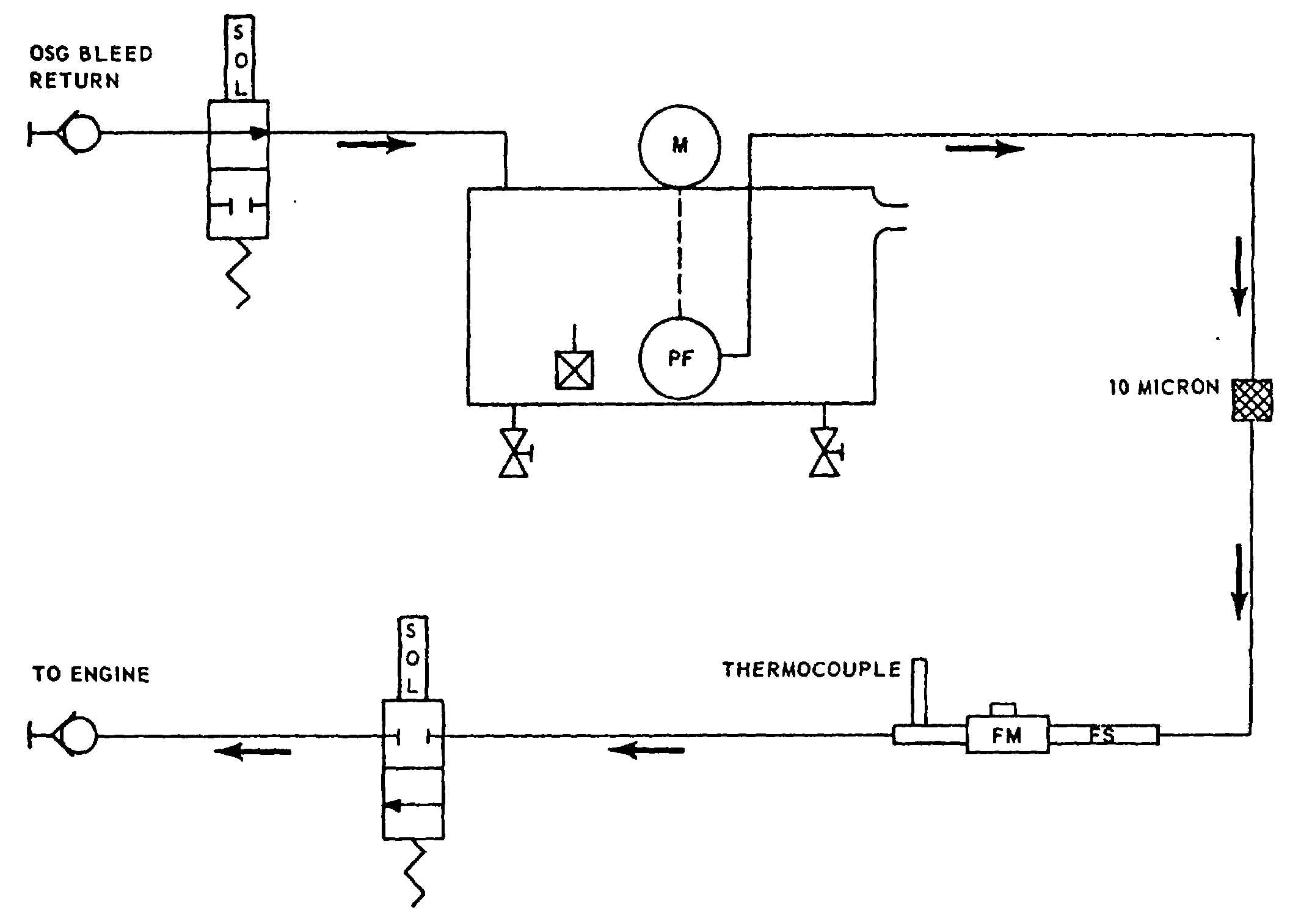

Figure 1-11. Test Trailer Fuel System Schematic Diagram.

(7) Test trailer oil system.

(a) The test trailer oil system (figure 1-12) is

used to supply turbine lubricating oil to an engine under

test. Table 1-1 specifies the types of oils used. The

system has the capability, when required, of supplying

preheated oil to the engine being tested. The oil

system, except for the lubricating oil unit (6), is installed

below the test trailer deck on the left side of the unit.

The lubricating oil unit is located on the upper left side

of the deck. The oil system (shown schematically in

figure 1-13) consists essentially of a motor and pump

assembly (7, figure 1-12), suction strainer, and heat

exchanger (13). The system also includes a check

valve (3), relief and bypass valve (2), 40-micron filter

(11), manual valve (1), temperature regulating valve

and probe (9), manual selector valve (10), and two back

pressure regulators (12). The unit is provided with an

immersion heater (20) for preheating the oil, when

required, and with a fluid level transmitter. The

corrosion-resistant oil reservoir of the lubricating oil unit

has a capacity of 15 gallons and is provided with a

combination fill cap, vent, and strainer (15), and a drain

plug (8) for a fluid drainage, when required. An oil level

sight gage (5) and thermostat are installed on the left

side of the unit.

(b) With system power available from the

generator set and the INST POWER SUPPLY circuit

breaker CB5 (13, figure 2-9) energized, the LUBE

PUMP circuit breaker CB6 (2) is energized. This action

makes 117v ac, 60 Hz power available at the control

power module (Unit 5). With the INST PWR ON switch

S1 (7, figure 1-26) in the energized position, the OIL

PUMP START switch S17 (15) is depressed. This

action energizes the coils of the heavy-duty contactor

contained in the

1-15