TM 1-1500-204-23-1

·

When hot starts or tall pipe temperatures

exceed maximum allowable limit for given

operating condition, inspection or replacement

shall be accomplished in accordance with the

applicable maintenance manual.

·

When oil system is contaminated with metal

particles,

proceed

as

directed

in

the

maintenance manual.

b.

Component Replacement. Criteria Replace

individual turbine engine components as specified In the

applicable maintenance manual.

8-8. Marking of Defects on Turbine Engines.

Defects In removed parts may be marked by use of a

felt-tip marker.

8-9. Turbine Engine Mounts. A typical engine

mounting

system

consists

of

bipod

and

tripod

assemblies braced by tube assemblies. For specific

details of the system, refer to engine section of the

applicable maintenance manual. Repair bent, distorted,

or chafed areas of mount as specified in the applicable

maintenance manual. After repair of any component of

engine mount, accomplish a thorough visual and

magnetic particle inspection.

8-10. Preservation and Depreservation of Turbine

Engines. The preservation and depreservation

procedures for each type of turbine engine is specified

In the applicable aircraft maintenance manual

8-11. Removal and Installation of Turbine Engines.

Removal and installation of turbine engines is explained

In the following paragraphs. Refer to the applicable

maintenance manual.

a.

Preparation for Removal. Accomplish the

following general steps before removal.

(1) Adequately secure the aircraft either with

wheel chocks or with tiedown provisions; attach ground

wire or cable to aircraft.

(2) Open the nacelle doors and support them

with the struts. Verify that no external power is

connected to the aircraft and that the electric power

switch is off.

(3) Remove the mount access plates from both

sides of the nacelle structure.

(4) Remove the engine air-conditioning duct

access plate, and disconnect the duct from the engine.

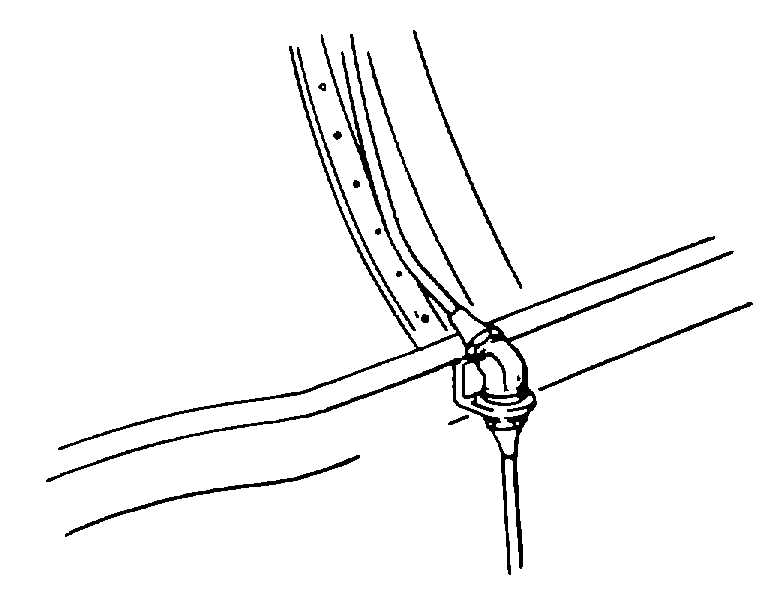

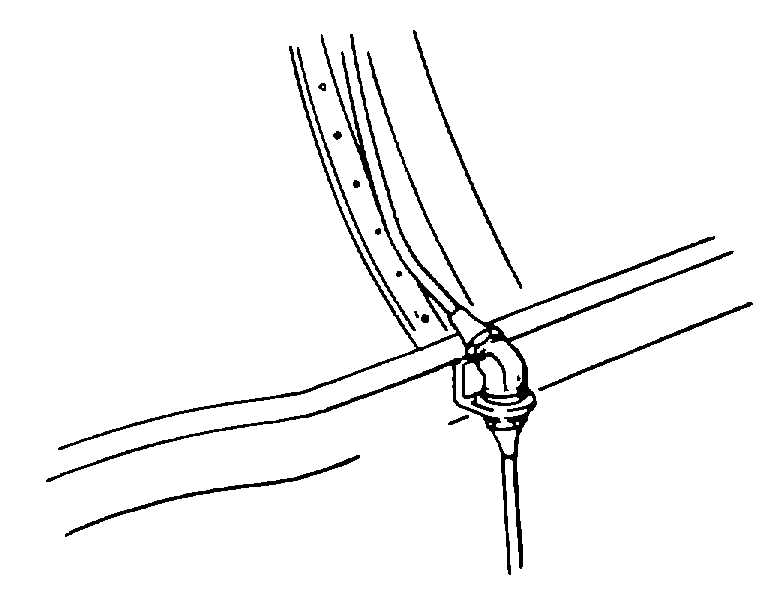

(5) Disconnect the turbine discharge pressure

pickup line as shown in figure 8-19.

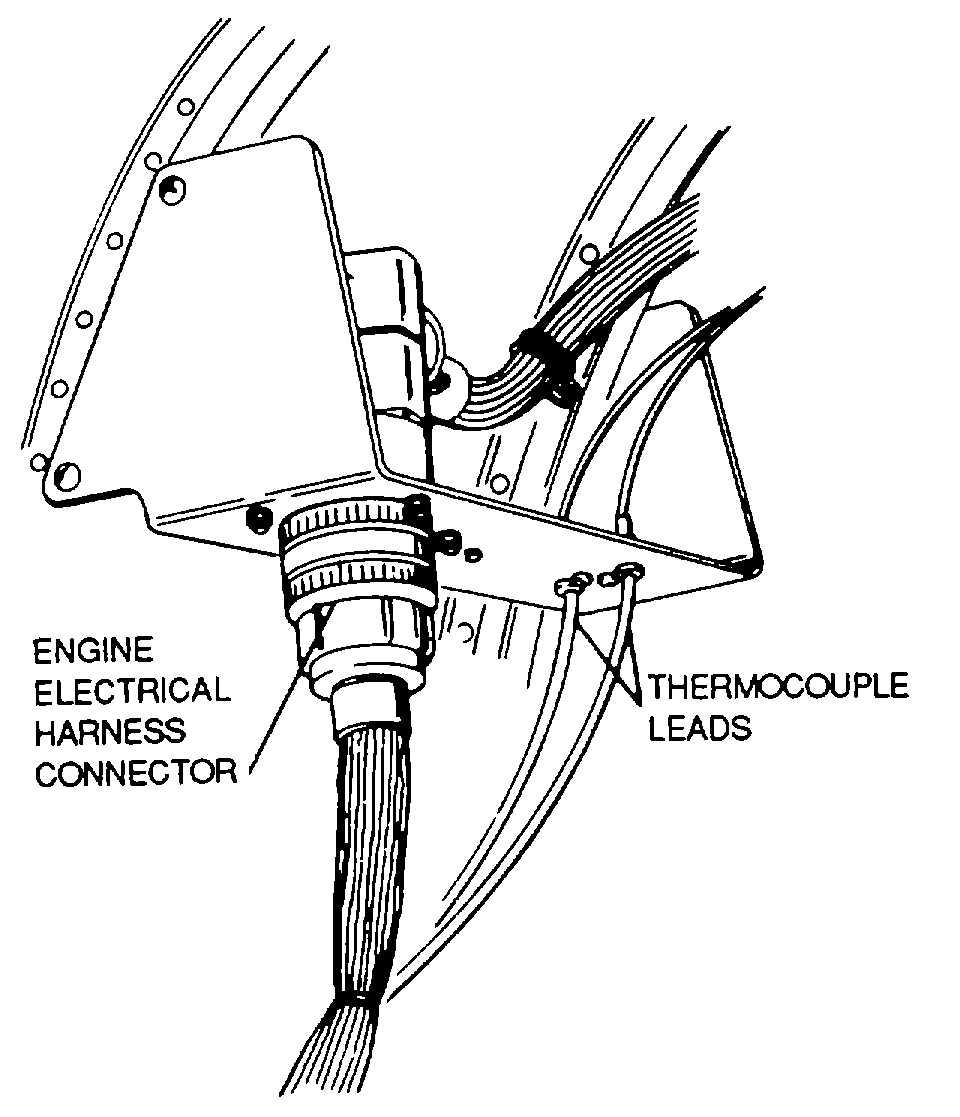

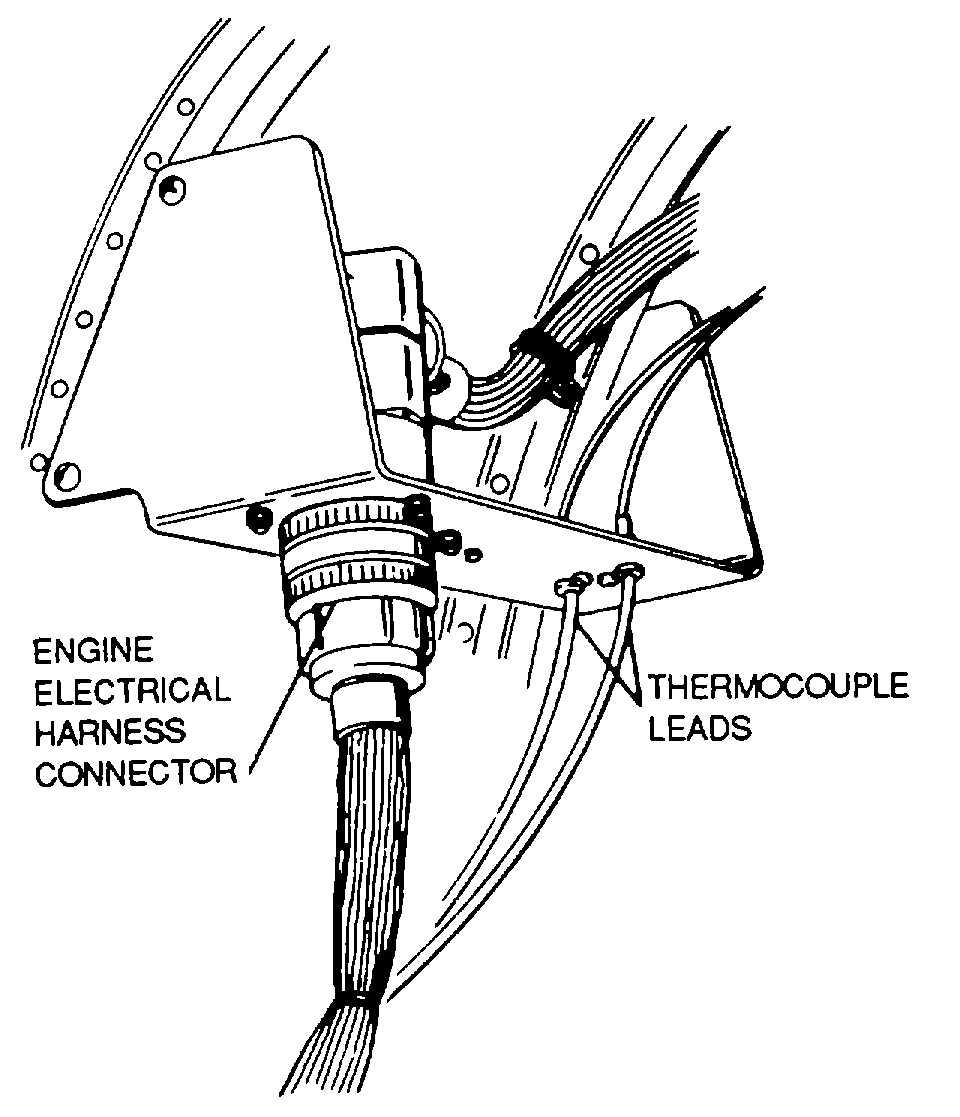

(6) Disconnect the electrical wiring and the

thermocouple leads from the connectors as shown in

figure 8-20.

(7) Disconnect the fuel line by removing the

bolts from the hose flange as shown in figure 8-21.

Figure 8-19. Turbine Discharge Pressure Pickup

Line

Figure 8-20. Electrical Disconnect

8-20