TM 1-1500-204-23-1

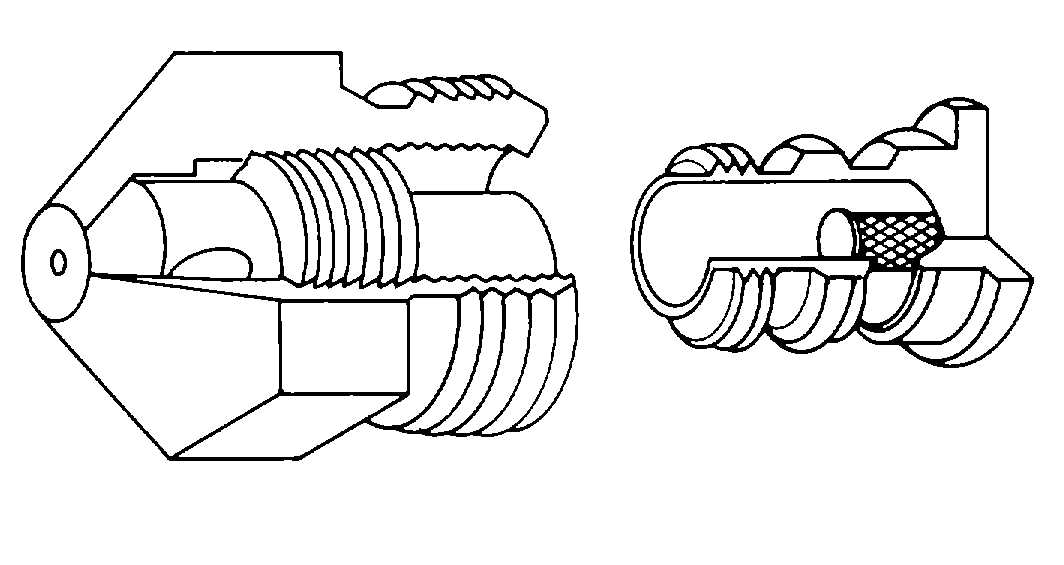

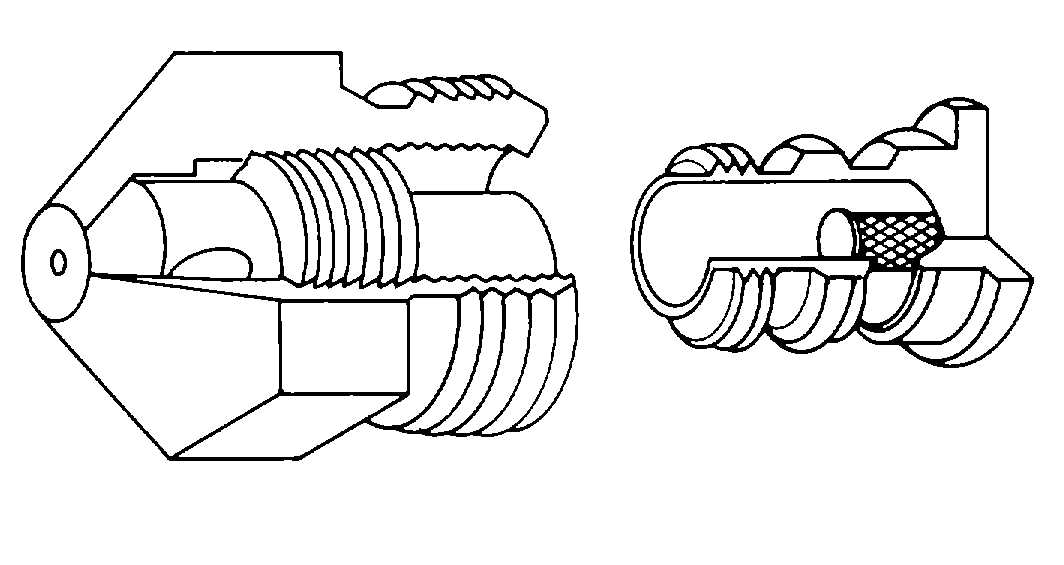

Figure 8-15. Simplex Fuel Nozzle

a. General Procedures. The following procedures

shall be adhered to during turbine engine maintenance.

(1) Mark location of all attaching support brackets,

clamps, and clips prior to removing lines, tubes, or

conduit to facilitate reassembly with a felt tip marker

Use ink conforming to Federal Specification TT-1-544.

(2) Use new O-rings, packing rings, cotter pins,

lockpins, gaskets, and washers.

(3) Apply lubricating grease, MIL-G-4343, on all O-

rings prior to installation.

(4) Apply thread compound, MIL-A-13881, to all

threaded parts attached to the hot section.

(5) When gears are replaced, examine for pattern

wear and backlash.

b. Health Indication Test. The Health Indication Test

(HIT) is the method by which the aviator In day-to-day

flying monitors the aircraft engine condition. This is

accomplished by the aviator selecting an N1 speed (%)

predicated upon the existing Free Air Temperature

(FAT). The interstate Turbine Temperature (ITT) must

then relate to a predicated value (Baseline ITT) within a

certain tolerance. ITT variation from baseline values

are logged by the aviator in accordance with the

applicable maintenance manual This log, part of the

engine records, is available to the maintenance officer

as an aid In monitoring performance trends and in

troubleshooting

When

the

difference

between

a

recorded ITT and the baseline ITT is 20 °C (68

°F) or

greater the aviator will make an entry on DA Form 2408-

13 to notify the maintenance officer. A difference of

30C (86°F) or greater is cause for grounding the aircraft

until troubleshooting determines the cause of the

excessive ITT. New ITT baseline values for HIT should

be established after performing a baseline engine

performance check. A new engine performance check

should be made when an engine Is changed, when the

fuel control unit is adjusted or replaced, or when repairs

are made to the engine hot section.

c. Hot Start Inspection. A hot start occurs when

exhaust gas temperature exceeds normal starting

temperature limit.

NOTE

A hot start may be expected when a

greater-than-normal starting fuel flow

Is observed just as the power lever is

moved Into the IDLE position.

d. Turbine Engine Analysis Check (TEAC). A normal

Turbine Engine Analysis Check (TEAC) is performed for

comparison of normal TEAC data with baseline data.

This

will

confirm

whether

or

not

performance

degradation has occurred and to what degree. In

addition, TEAC data can be an aid in determining the

cause of the performance loss (Refer to TEAC

troubleshooting). A normal TEAC shall be performed

whenever installed engine performance degradation Is

suspected or as part of a general test flight (if

applicable).

e. Foreign Object Damage Inspection. Most damage

incurred by the engine is the result of ingestion of

foreign objects Although screens are provided in the

lower aft cowling section and around the engine

compressor inlet case to prevent entry of larger objects,

sand and grit will enter and cause compressor damage.

The resultant damage will be in the form of nicks or

scratches on the compressor blades. Such a nick or

scratch can cause fatigue failure hours later, with

disastrous effects to the entire engine.

CAUTION

When maintenance is performed on

the engine, every effort shall be

made to retrieve any object (wire,

rivets, nuts, screws, etc.) dropped

through the compressor inlet screen

or into the cowling, even if engine

disassembly Is required. Damage to

the engine may otherwise result.

8-13