TM 1-1500-204-23-1

oll-flltering screens, Cuno filters, and other items of

accessory equipment. In some aircraft powerplants, the

cover for the supercharger rear housing is made of an

aluminum-alloy or a magnesium-alloy casting in the form

of a heavily ribbed plate that provides the mounting pads

for the accessory units; but in other powerplants, the

housings for the accessory units may be mounted directly

on the rear of the crankcase. Regardless of the

construction and location of the accessory housing, it

contains the gears for driving the accessories which are

operated by engine power.

(2)

Maintenance. Crankcase maintenance

consists of inspection for cracks, warping, damage to

machined surfaces, warn bushings and bearing bores,

loose or bent studs, corrosion damage, and other

conditions which may lead to failure in service Refer to

the applicable maintenance manual

NOTE

Two-piece

crankcases

are

manufactured with matched parts;

therefore

it

one

half

must

be

discarded, the entire crankcase is

replaced

b.

Crankshafts. The crankshaft transforms the

reciprocating motion of the piston and connecting rod into

rotary motion for turning the propeller It Is a shaft

composed of one or more cranks or throws The parts are

the main journal, crankpln, crank cheek or crank arm, and

the

counterweights

and

dampers

The

following

paragraphs describe crankshaft types and general

maintenance.

(1)

Types. Opposed-type and radial-type

engine crankshafts are described in the following

paragraphs.

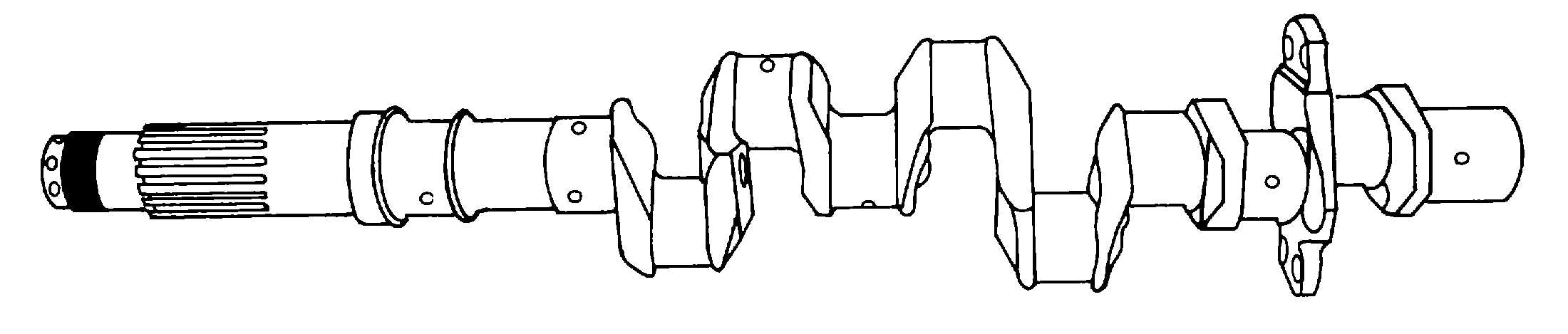

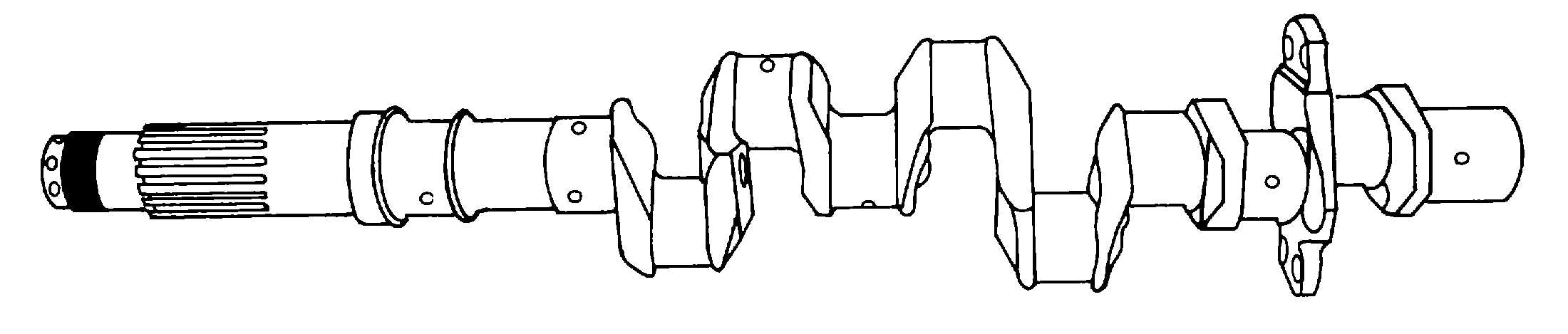

(a)

Opposed-type crankshaft. A typical

six cylinder opposed-type crankshaft is shown in figure 7-

6. This crankshaft is a one-piece, six-throw, 60-degree

crankshaft machined from an alloy-steel (SAE 4340)

forging. The crankpins and main bearing journals are

ground to close limits of size and surface roughness.

(b)

Radial-type crankshaft. Figure 7-7

shows a single-throw 360-degree crankshaft used on

single-row radial engines. It may be of single-piece or

two-piece construction with two main bearings (one on

each end) This single piece crankshaft must be used with

a master rod having the large end split

(2)

Maintenance. Crankshaft maintenance is

critical to safe engine operation. The dimensions of the

journals, the balance, and the alignment of the shaft must

be within tolerances when inspected and measured. The

crankshaft should be inspected by the magnetic methods

to detect flaws and defects. Refer to the applicable

maintenance

manual

for

specific

maintenance

procedures and tests.

Figure 7-6. Opposed-Type Crankshaft (Six-Cylinder) (Six-Throw)

7-4