TM 1-1500-204-23-1

(a)

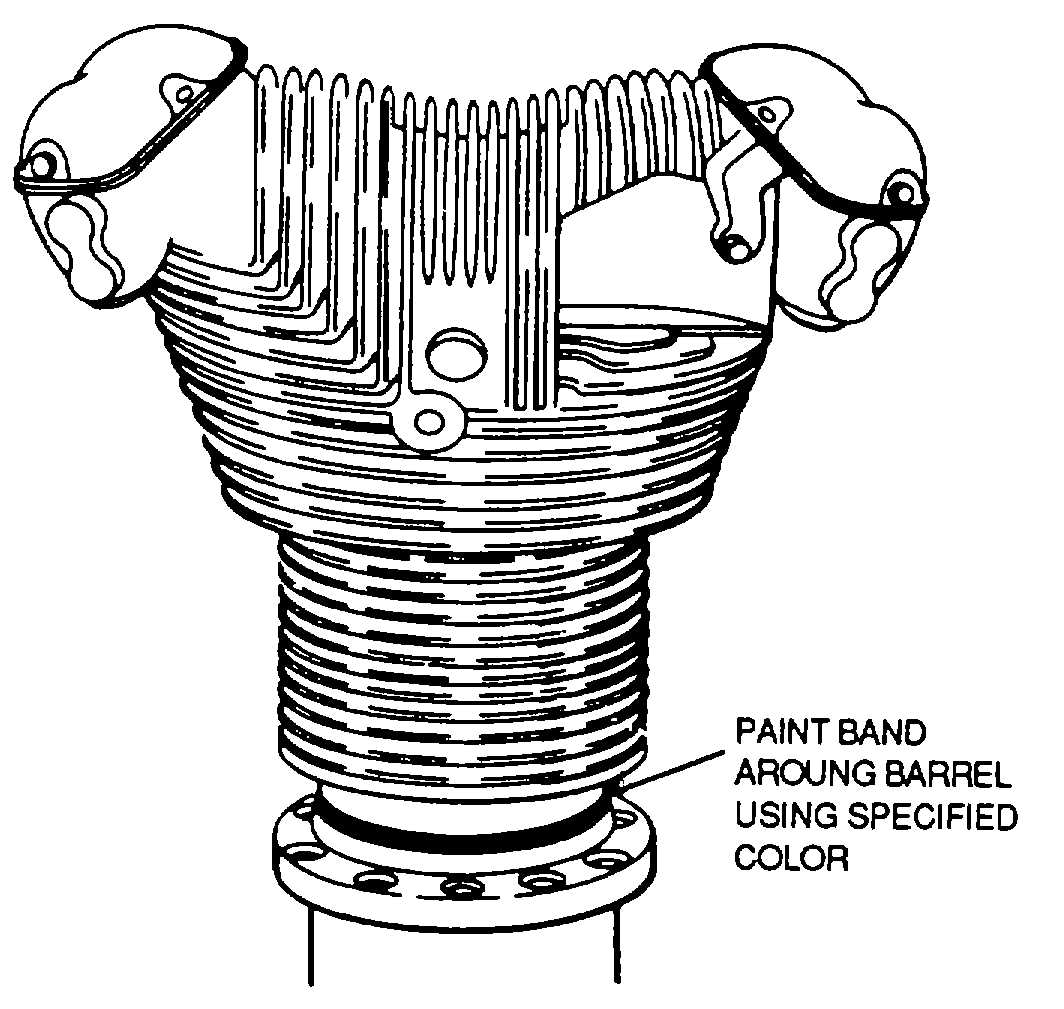

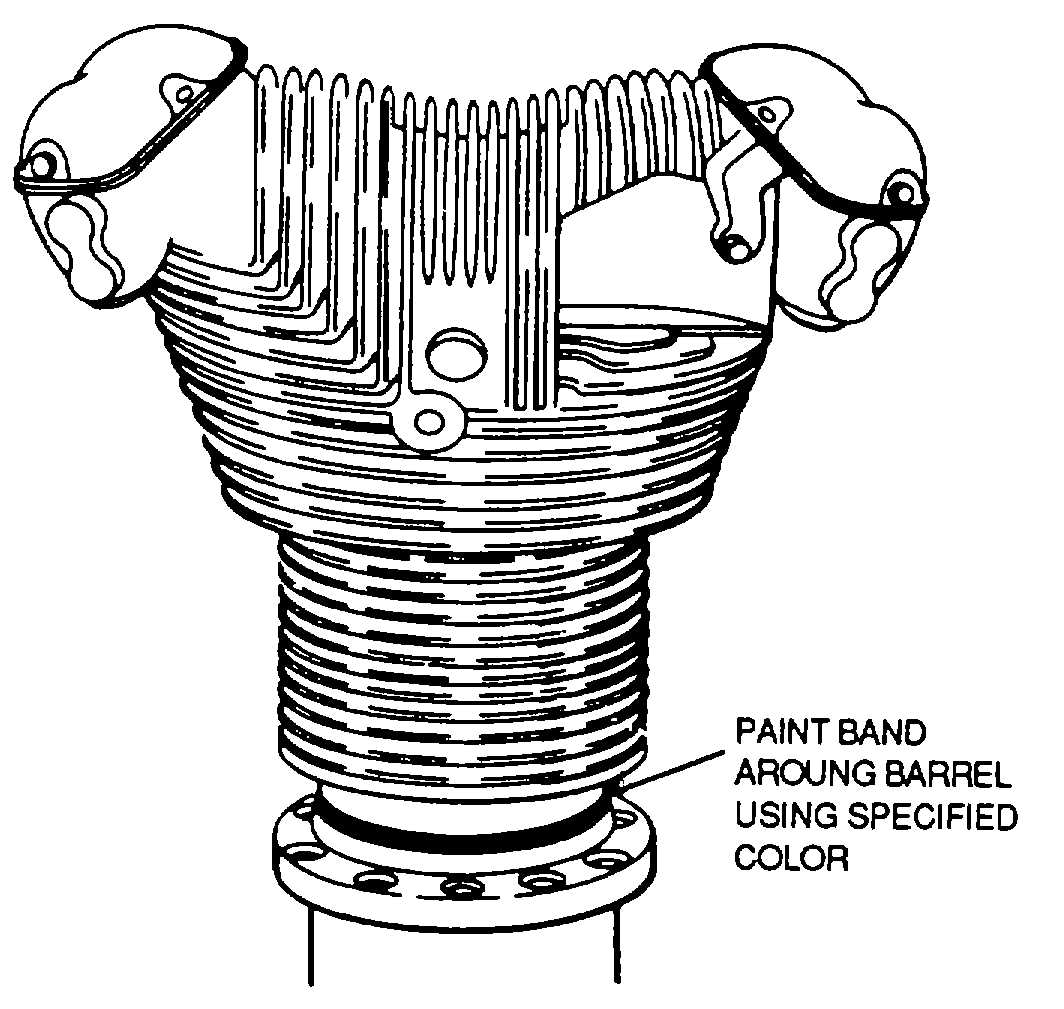

Identification. Cylinders will be color

coded around the barrel between the attaching flange and

the lower barrel cooling fin with a 1/2-inch wide band of

enamel, heat-stable, cadmium sulphide paint (see figure

7-12). The cylinder sizes and colors are listed below

Standard Cylinder - Aluminum or Black

Chrome Plated - International Orange

0.010 Inch Oversize - Green

0.015 Inch Oversize - Gray

0.020 Inch Oversize - Yellow

NOTE

Chrome-plated cylinders are further

Identified

as

illustrated

In

the

following example 6-44, SAX-3, 20

would designate the third cylinder

plated by San Antonio Air Material

Area in June 1944, and the cylinder

was 0.020 inch oversize when plated.

(b)

Liquid lock. When an engine is shut

down, the warm residual oil clinging to the power section

surfaces flows downward toward lower cylinders. Some

of this oil seeps past piston rings, accumulating in the

combustion chamber. When sufficient liquid is present,

the true compression ratio will be raised and extremely

high pressure will be produced when the piston moves

down on the compression stroke. These pressures can

damage the cylinder, piston, or rod. The piston may

actually press the liquid, forming what is known as a

hydraulic or liquid lock (see figure 7-13). Observe the

following precautions:

CAUTION

Do not rotate propeller in reverse

direction of normal engine rotation.

This will push the liquid Into intake

pipes and return to cylinders on the

next intake stroke.

When propeller is rotating in the normal

direction, the operator must be alert for any sign

of

piston

being

forced

against

high

compression,

evidenced

by

a

sudden

resistance, slowdown, or stoppage which would

indicate an excess amount of liquid in the lower

cylinder

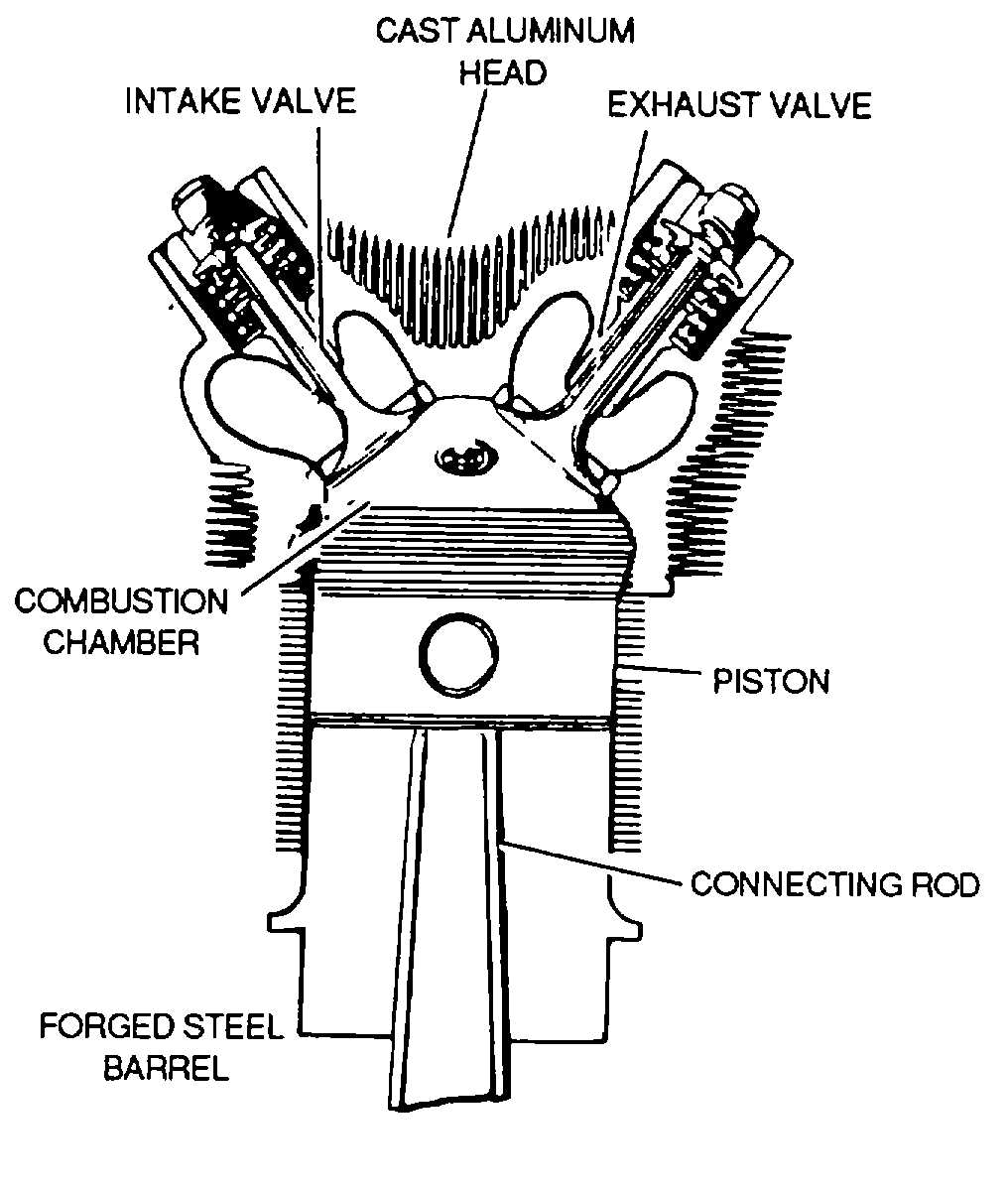

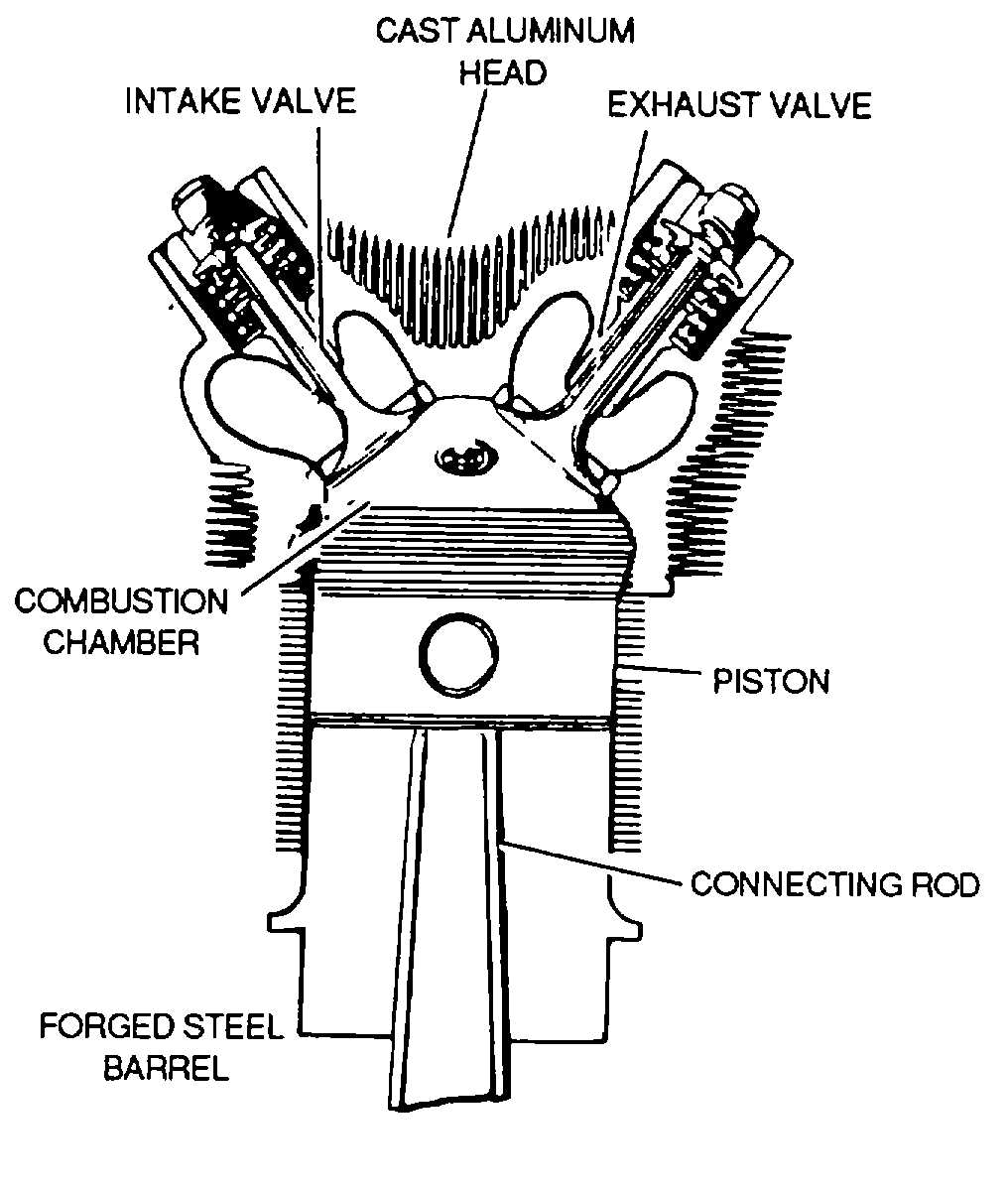

Figure 7-11. Cylinder Assembly

Figure 7-12. Marking of Cylinder

7-9