TM 1-1500-204-23-1

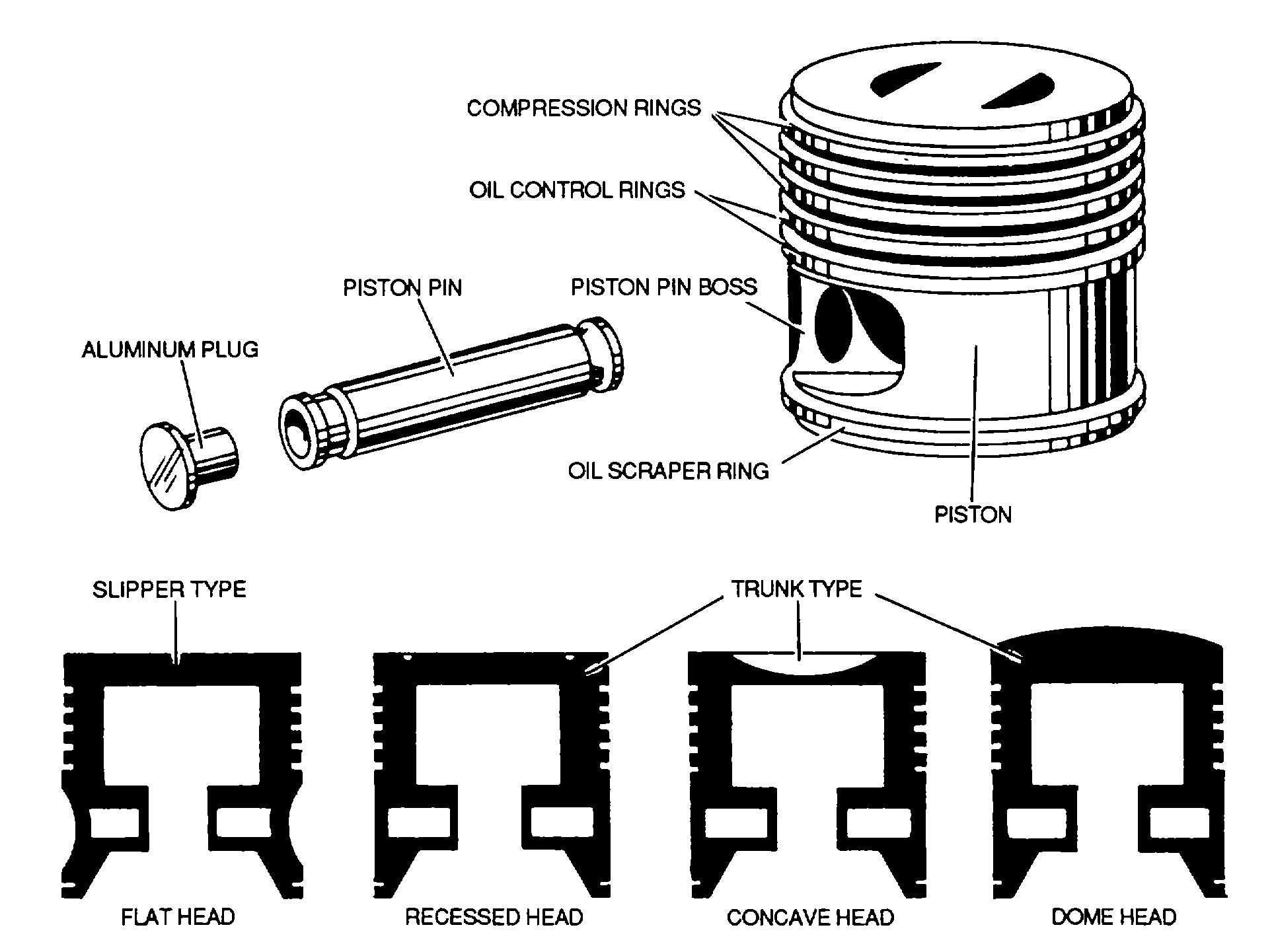

Figure 7-10. Piston, Pin, and Ring Assemblies

(2)

Maintenance.

Cylinder

maintenance

procedures are explained in the following paragraphs. All

openings to a cylinder must be completely closed and

sealed during the compression and power strokes In order

to maintain proper compression and thus prevent power

loss. The requirements for proper sealing are: good

piston rings with no leakage between pistons and walls of

the combustion chamber, tightly closing. Intake and

exhaust valves, and proper valve timing to ensure highest

efficiency obtainable when engine is operating at its

normal rpm. Compression loss at any of these points

results in reduced engine efficiency. Early detection and

correction of these faults will prevent cylinder breakdown.

Since most engine difficulties can be traced to a small

number of cylinders, engine malfunction can be corrected

by locating defective cylinders and taking corrective

action. Each phase of cylinder operation, such as

compression, fuel mixture, or ignition, must function

properly to maintain cylinder compression.

NOTE

Dark stains adjacent to the cylinder

head and barrel seam must not be

misinterpreted.

During

engine

operation,

the

high

temperature

thread lubricant used during barrel

and head assembly may be extruded

at

the

seam

leaving

a

heavy

discoloration. Such a condition is In

no

way

hazardous

to

engine

operation, therefore, verification of

cylinder failure must be by means

other than stains alone. A cylinder

should

be

removed

for

head

separation only if it displays visible

damage and/or fails the normal

compression test.

7-8