TM 1-1500-204-23-1

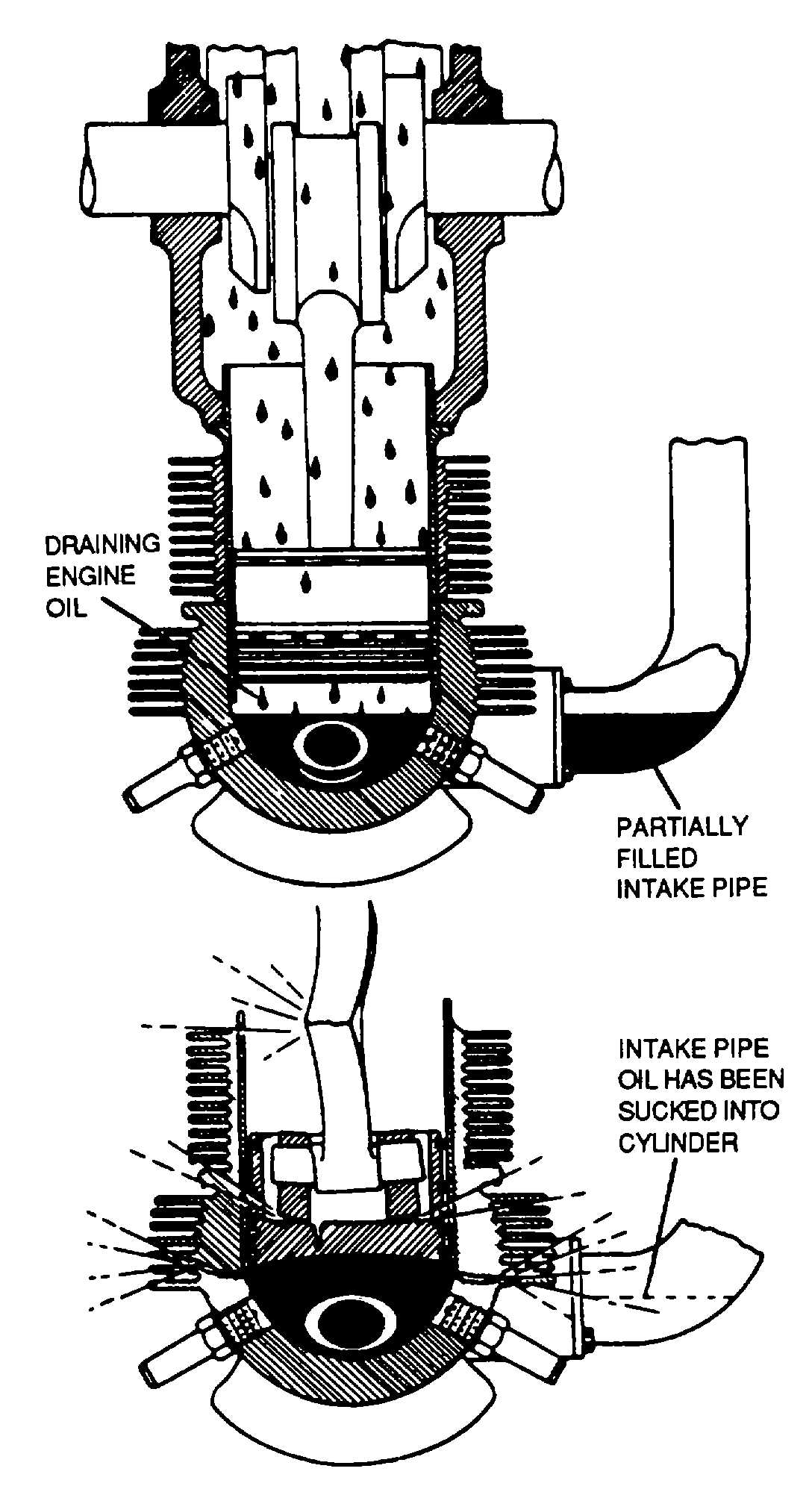

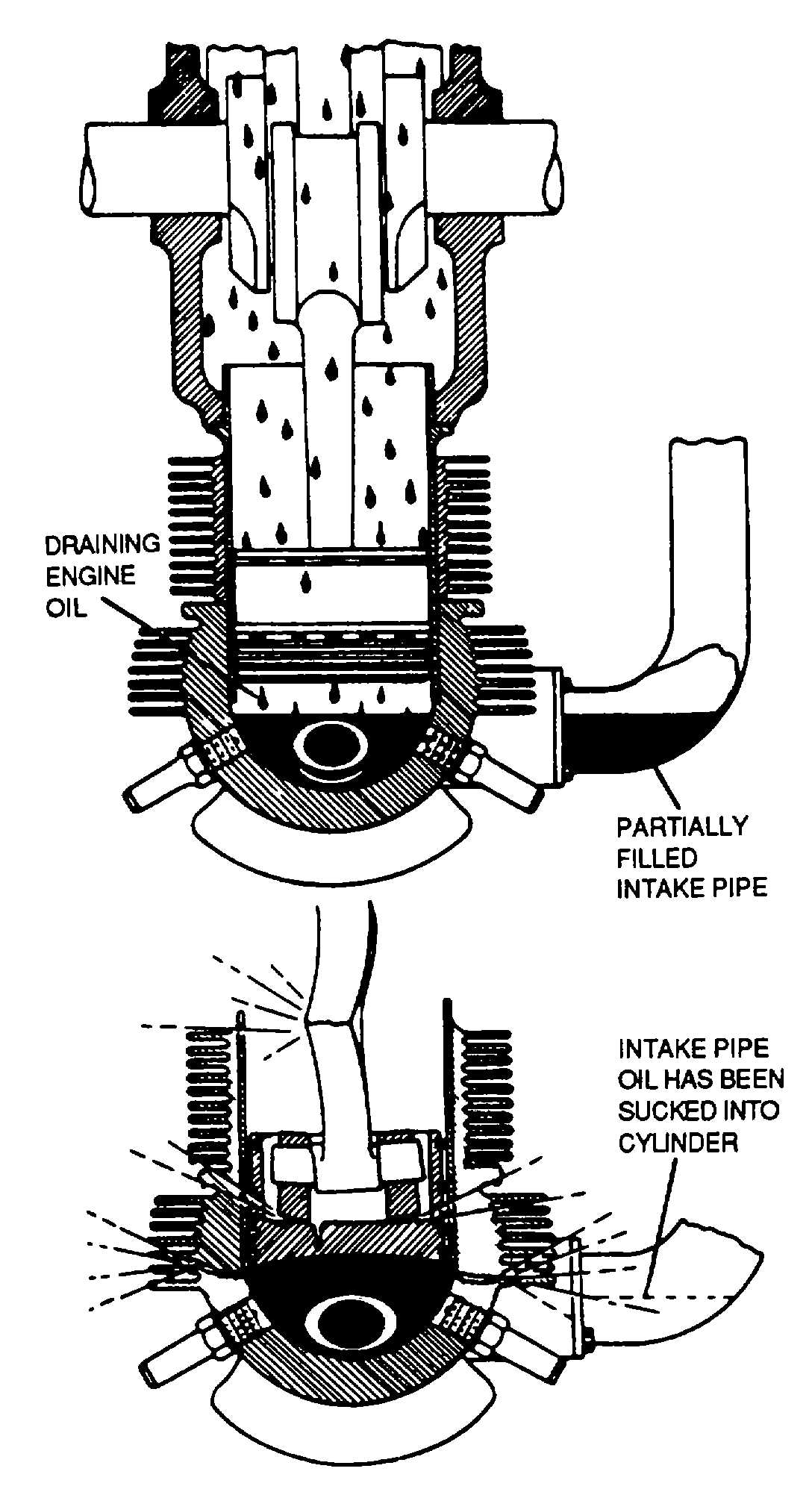

Liquid locks are partial or complete. Hesitation

in propeller rotation usually denotes a partial

lock. If propeller stops, it usually denotes a

complete liquid lock. Forcing engine through a

complete liquid lock will cause Immediate

engine failure.

Liquid locks are also caused by oil in intake

pipes

as

a

result

of

preservation,

fuel

discharged

into

the

intake

system

while

crankshaft is not rotating, or oil flowing from

push rod housing into rocker box, then seeping

through intake or exhaust valve guides into

intake or exhaust ports.

Due to the mechanical advantage of a long

propeller blade and the fact that two or more

men per blade are used for propeller pull

through, possibility of bending a rod by manual

pull-through is more likely than by starter pull

through. This is particularly true when a partial

liquid lock is present, since the piston with a

partial liquid lock will be very near the top of the

stroke when force. Is required to rotate the

crankshaft against the liquid lock Liquid lock

may bend the connecting rod slightly, but not

enough to move the lower piston ring out of the

cylinder skirt, on the downward stroke, in which

case internal failure may occur within the next

50 hours.

If liquid lock is suspected, remove a spark plug

from cylinder involved and allow liquid to drain

out. Turn propeller several revolutions to make

certain all liquid has drained from cylinder and

induction lines, then install clean spark plug.

(c)

Valve blowby. Valve blowby is

Indicated by a hissing or whistling sound when engine is

pulled through by propeller, turned with starter, or while

idling at low speed. Correct valve blowby by first

checking valve clearance and adjust as necessary. If

valve clearance is excessive, proceed using the following

procedures.

NOTE

If valve is stuck in the valve guide,

correct

clearance

cannot

be

determined.

1

Stake valve by placing a fiber drift

on rocker arm and valve stem, and then drift with a

hammer.

2

Determine

whether

blowby

has

been eliminated by turning engine by hand or turning it

through with starter.

3

When

blowby

is

still

present,

perform a compression test.

Figure 7-13. Liquid Lock

7-10