TM 1-1500-204-23-2

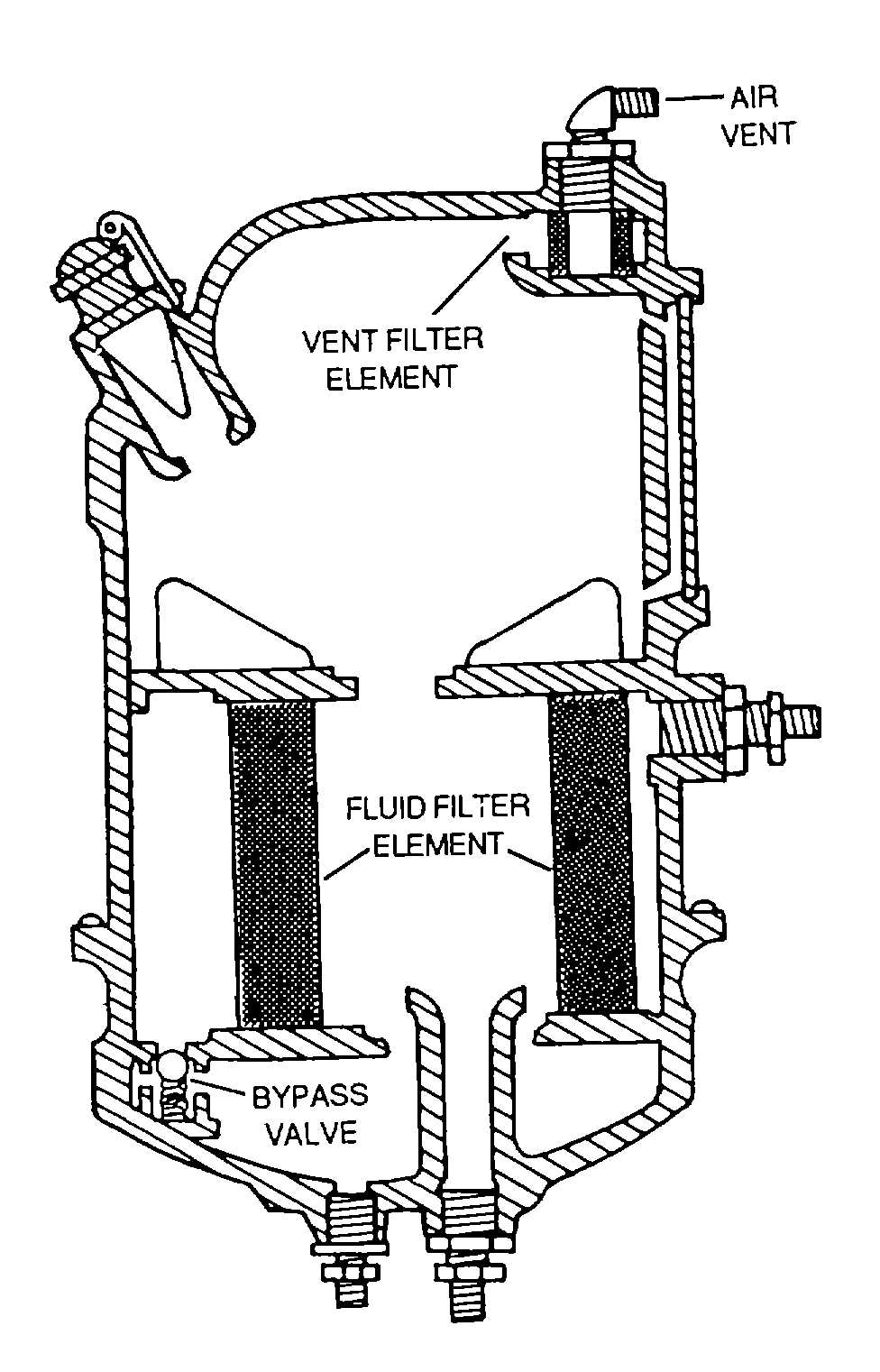

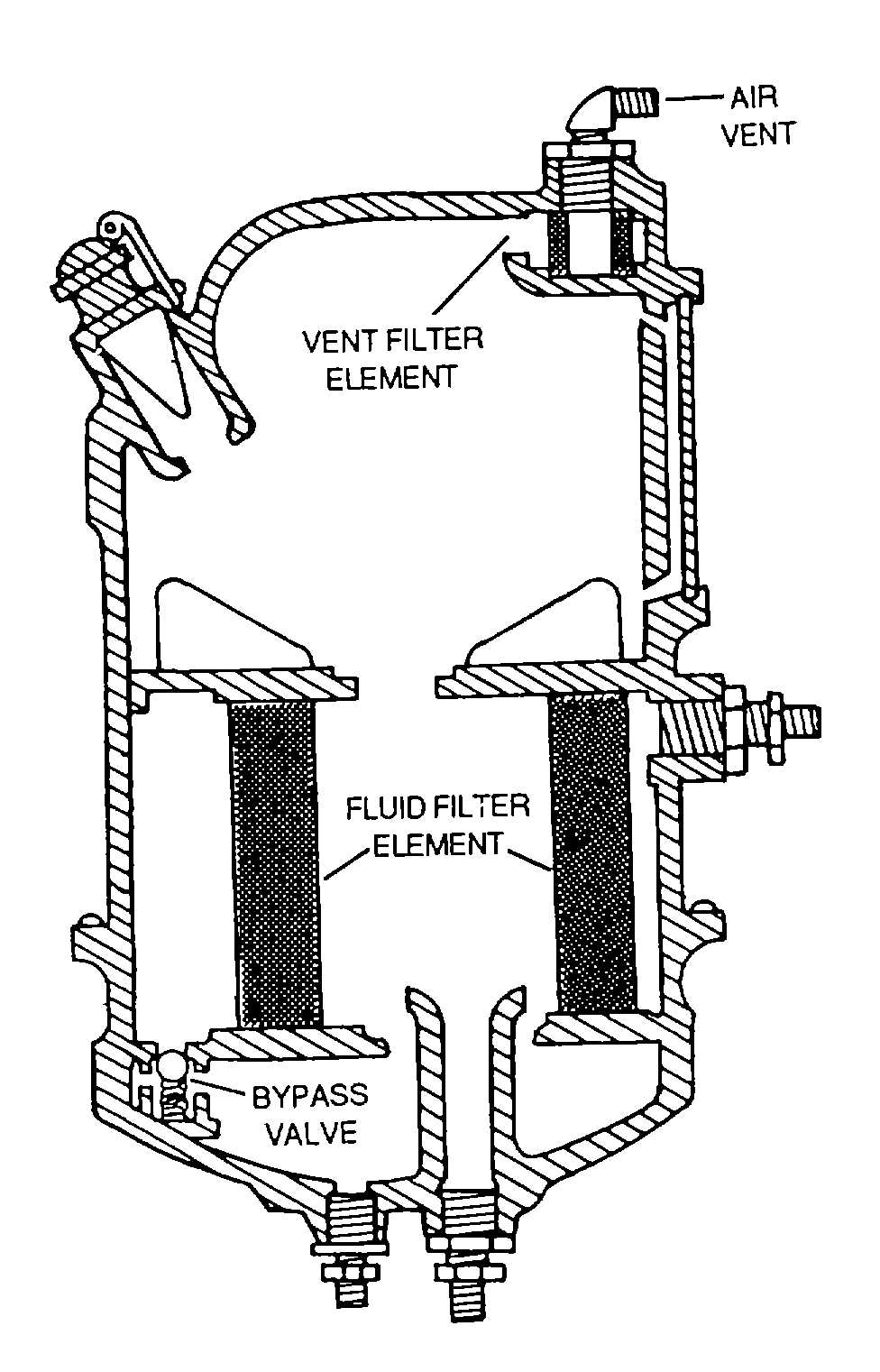

Figure 4-94. Reservoir with Filter Elements

CAUTION

The use of any alcohol in cleaning components which contact hydraulic fluids is prohibited. Formation of a

polymeric residue can result which could impair mechanical operation of the component.

(2) Replace filter element when signs of cracks or tears are noted. Replace filter screens that show signs of

deterioration.

(3) Refer to the applicable aircraft maintenance manual for detailed assembly and maintenance requirements.

4-12. Hydraulic System Filters. Practically all foreign particles found in hydraulic fluid can be removed by filters. The

degree of filtration needed depends on the acceptance level desired Most high pressure hydraulic systems use filters

having a 10- to 15-micron capability, but many later model aircraft have 5 micron filters; and two-stage filters, one

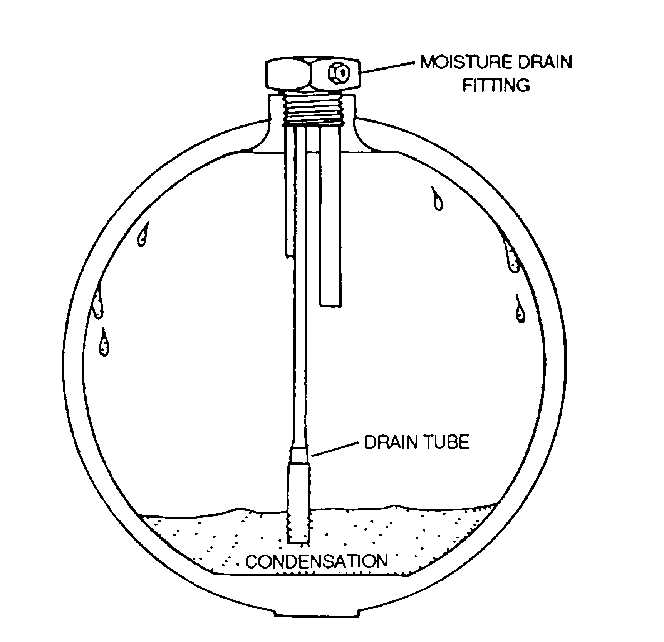

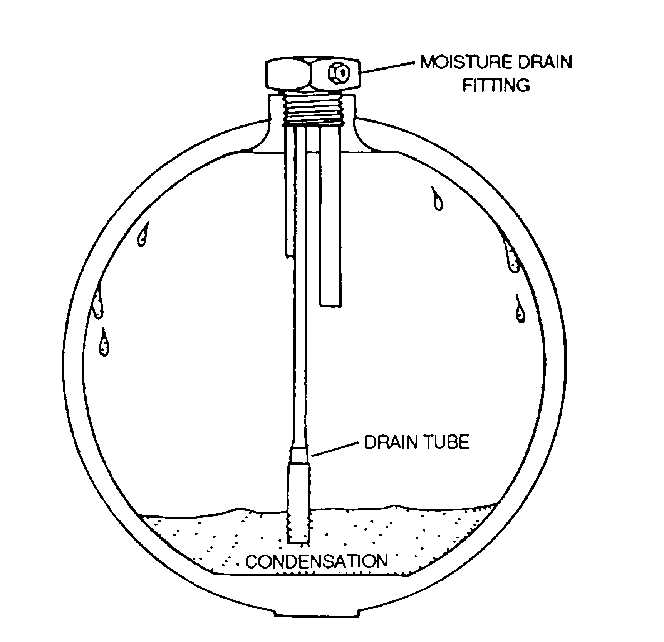

Figure 4-95. Spherical Air Cylinder

element of which has a 3-micron capability, are found In some recent models. They are Intended primarily to safeguard

the operation of certain important units by filtering out foreign particles generated by wear and tear of parts in the system.

They cannot handle large quantities of foreign matter from outside the system a Uses of Filters in Hydraulic Systems.

Filters are sometimes used In reservoirs. In addition, they may be located in the pressure line, In the return line, or In

any other location where they are needed to safeguard the system against foreign particles in the fluid How- ever, filters

are not normally used In system supply lines There are many models of filters, the variation being necessitated by the

location of the filter within the particular aircraft.

b.

Theory of Operation. The size and shape of each element depend on Its use and installation; however, all line

filter assemblies are made up of three basic units: filter head, filter case, and filter element. Figure 4-96 shows a typical

line filter assembly In which the differential pressure indicator is located In the top of the filter head assembly (in some

designs the indicator is located on the side of the filter head assembly). Also located within the head is a bypass valve

assembly which routes hydraulic fluid directly from the inlet to the

4-105