TM 1-1500-204-23-2

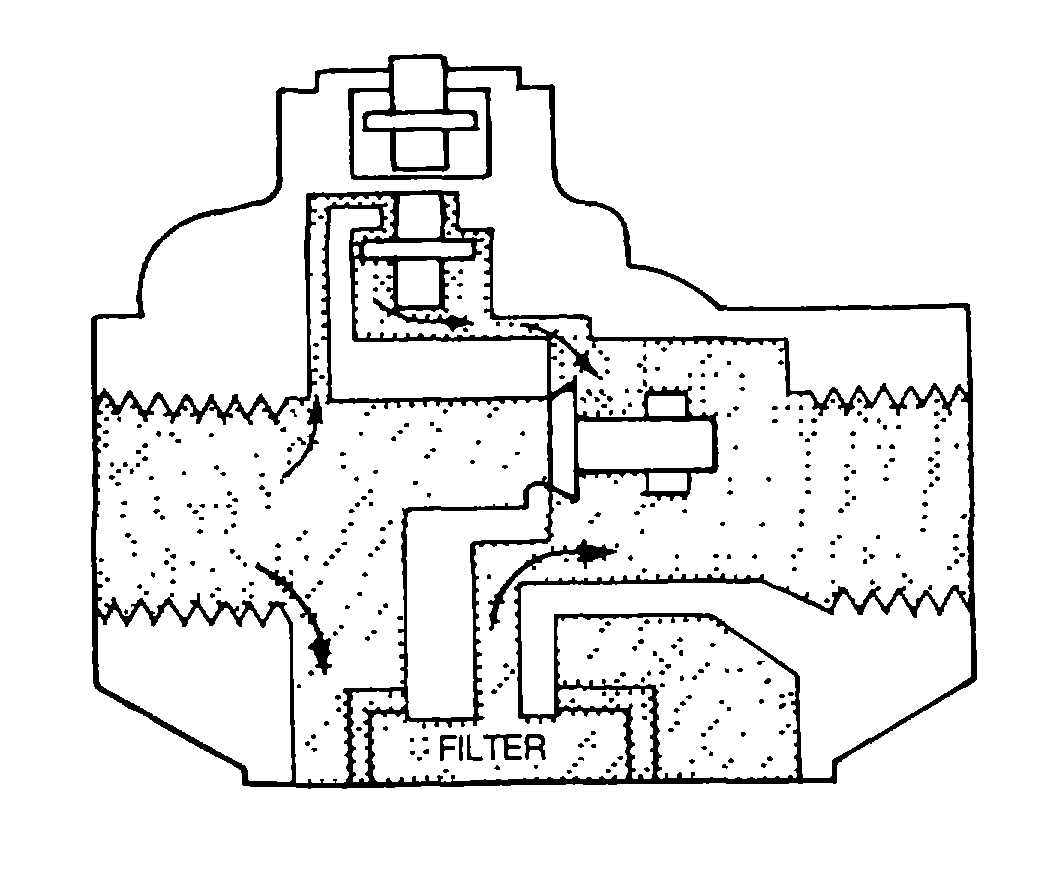

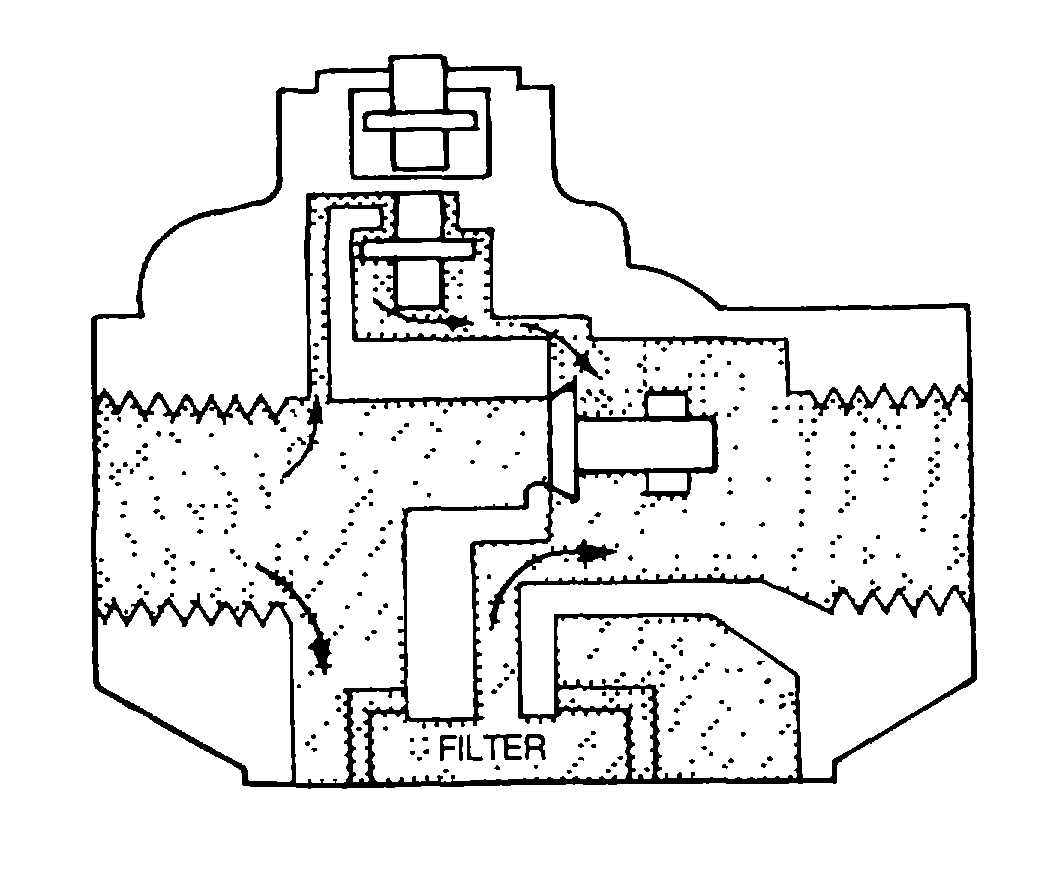

(a) Operation. Figures 4-99 and 4-100 show the indicator during normal flow and during bypass. As

contaminating particles collection the outside of the filter element, the differential pressure across the element increases.

When this increased pressure reaches a specific value, inlet pressure forces the spring-loaded magnetic piston

downward breaking the magnetic attachment between the indicator button and the magnetic piston. This allows the red

indicator to pop out, showing that the element must be cleaned. Because increased fluid viscosity at low temperatures

might cause a false indication of contamination, a low-temperature lockout of the differential pressure indicator prevents

actuation at low temperatures.

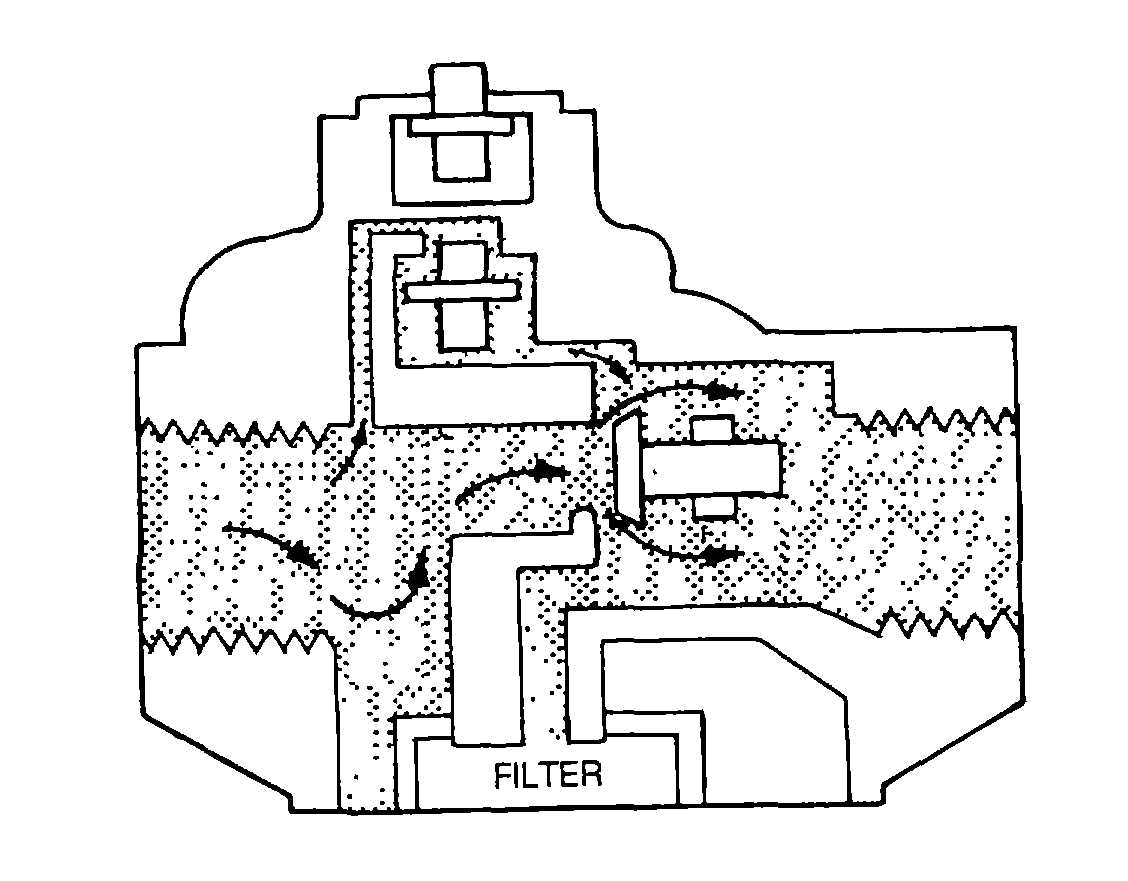

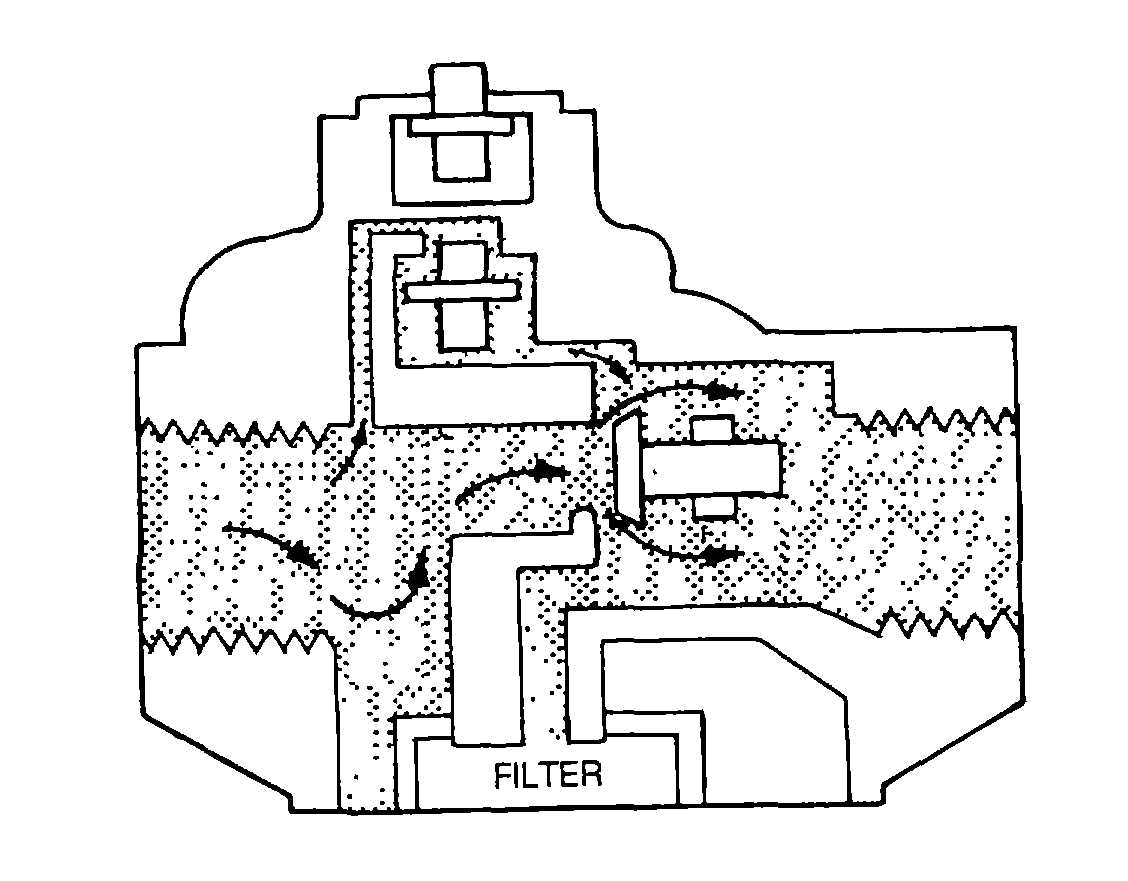

(b) Bypass. If the filter element Is not replaced when the indicator shows contamination, the filter element

will continue to collect foreign particles and the pressure differential between the inlet and outlet ports will increase until

the bypass valve opens and directs fluid through the filter element bypass. The use of a non-bypassing-type filter

eliminates the possibility of contaminated fluid passing the filter element and contaminating the entire system. This type

of filter will minimize the need for flushing the entire system and will lessen the chance for failure of pumps and other

components in the power system.

Figure 4-99. Differential Pressure Indicator (Normal Flow)

c.

Filter Elements. The filtering elements In fluid filters are normally made of paper or of stainless steel. Paper

elements are used mostly In low pressure systems and are thrown away when removed. Stainless steel elements are

used in both high pressure and low pressure systems and may be reused.

(1) Paper elements. A typical fluid filter with a paper element is designed to remove 99 percent of all particles

10 microns (0.000394 inch) in diameter and larger. This element, like those used in the reservoir, is made of specially

treated cellulose paper formed in accordion-like pleats to present the maximum filtering surface to the fluid.

(a) Replacement criteria. Paper filter elements are replaced on a scheduled basis, depending on the needs

of the specific aircraft system. Unscheduled replacement of filter elements is also required following removal of certain

components.

(b) Removal and replacement. The following procedure for removing and replacing paper filter elements is

typical of most Army aircraft.

1

Relieve system pressure by operating the main system bypass valve or by actuating a

hydraulically operated unit.

Figure 4-100. Differential Pressure Indicator (Clogged Filters)

4-107