TM 1-1500-204-23-2

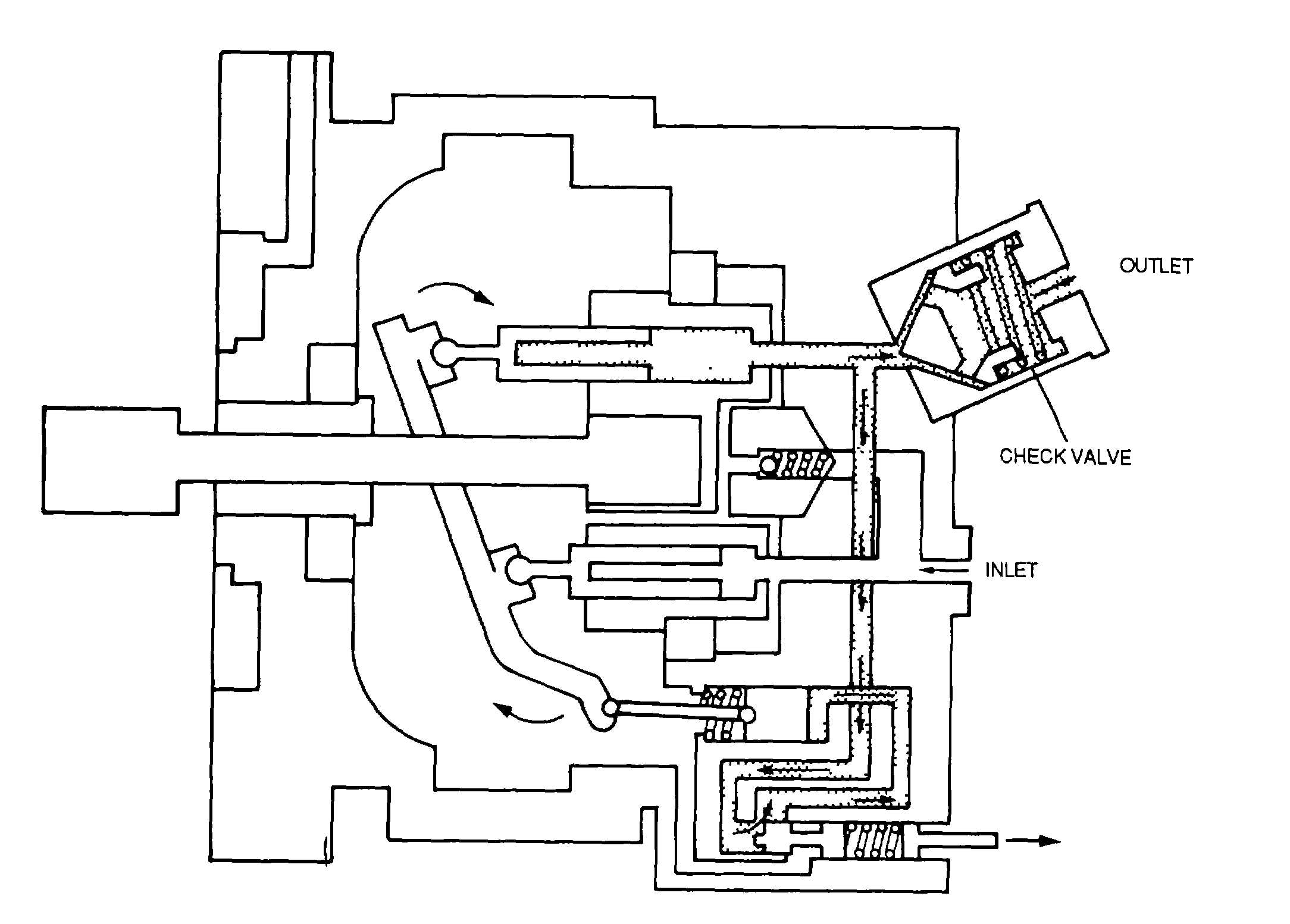

Figure 4-110. Kellogg Stroke Reduction Pump (Reduced Output)

plate assumes various angles to maintain the proper system pressure. It will meet all fluid demand conditions within the

rating of the pump. A pump check valve installed in the pump outlet line prevents return flow into the pump during

operation of the system with a portable test stand. Reverse flow of hydraulic fluid would motorize the pump.

b.

Maintenance of Power Pumps. Repair and overhaul of hydraulic power pumps is done at depots. This

work requires special tools and equipment.

c.

Hand Pumps. Hand pumps serve as replacements for power pumps during emergencies in fright and as

sources of power for checking the hydraulic system when the aircraft is on the ground. They are piston-type pumps and

may be either single or double action, however, most are the double-action type. Such pumps deliver fluid under

pressure on both the fore and aft strokes of the piston.

(1)

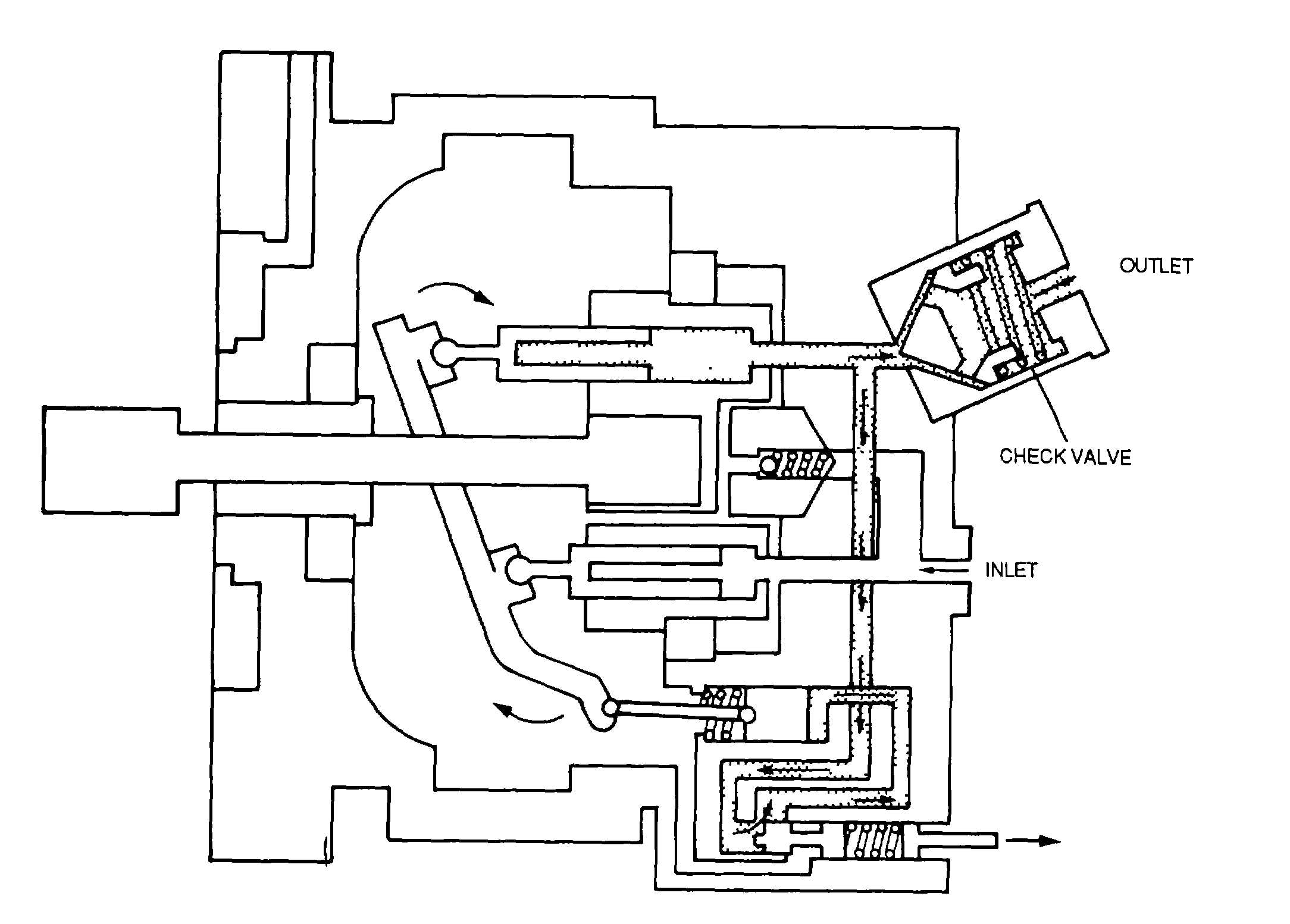

Description. The hand pump shown in figure 4-111 consists essentially of a cylinder assembly

containing a piston (3) and two springloaded check valves (5 and 4). When the piston moves to the right, the piston

check valve (4) is held closed by the spring. The piston forces the fluid in the right chamber (5) out into the pressure line

through the check valve. At the same time, the suction effect created in the left chamber (2) by the moving piston draws

fluid through the inlet line check valve (1), thus filling that chamber. When the piston moves to the left, the inlet line

check valve is held closed by the pressure of the fluid in the left chamber. The space available for the fluid in the right

chambers is now less than the space in the left chamber. This is caused by the piston rod displacement in the right

chamber; the excess fluid under pressure is driven out through the discharge port of the system.

(2)

Maintenance. Maintenance of hand pumps consists of disassembly, inspection, reassembly and

testing

4-117