TM 1-1500-204-23-6

NOTE

When using a hand tool, the tool handle

is to remain fully open during the cable

entry process (in both tool models). The

handle is to be actuated in the pre-set

tension model after the tension pawl is

engaged with the cable, and in the

adjustable tension model only after the

desired tension is achieved.

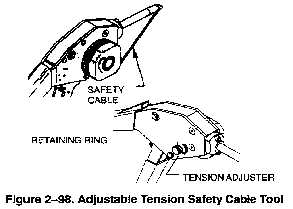

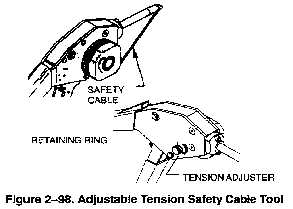

Figure 2-98. Adjustable Tension Safety cable Tool

c.

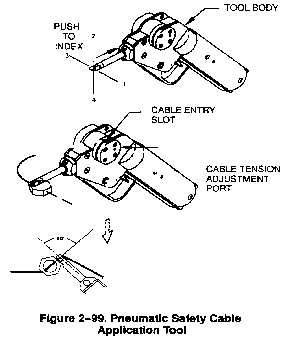

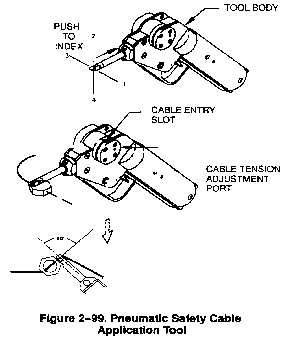

The Pneumatic Safety Cable Application

Tool. (See figure 2-99). Connect the pneumatic safety

cable tool to a clean, dry air supply of 80 to 100 psi.

(1)

Install the safety cable through the

fasteners which are to be secured.

(2)

The nose can be indexed to four

positions in 900 increments. To select the position,

push the nose in towards the tool and rotate to the

desired position. Release the nose. If the nose does

not lock into the indexed position, turn it slightly until it

snaps into position and locks.

CAUTION

Do not actuate the tool unless the

nose

is

locked

into

position.

Actuation of the tool without the

nose being locked will severely

damage the nose or other tool

components.

(3)

Insert the free end of the cable through

the ferrule in the cartridge and remove the ferrule by

pulling the cable away from the end of the cartridge.

Insert the free end of the cable through the nose of the

tool and slide the tool along the cable to the desired

position.

(4)

Rotate the cable tensioning wheel

clockwise if necessary to move the cable entry slot to an

accessible position. Align the nose such that the ferrule

is pressed squarely against the fastener. Make certain

that the ferrule is fully seated into the nose. Insert the

free end of the cable into the cable entry slot of the

cable tensioning wheel. When the end of the cable exits

the wheel, grip the cable and pull the slack from the

cable. Do not leave more than 1 1/2" of total slack in

the cable.

(5)

Press the trigger and hold. The tool

will apply tension to the cable, crimp and cut. When the

trigger is released, the crimp mechanism will retract

(after the cycle is complete), and the tool nose can be

moved from the ferrule. The excess cable shall be

discarded.

(6)

The tension is adjustable by inserting

the manufacturer supplied adjustment key into the

adjustment port located on the tool handle. Clockwise

rotation increases tension, and counter clockwise

rotation decreases tension.

Figure 2-99. Pneumatic Safety Cable Application

Tool

2-22. Safety Cable Application Tool Maintenance

and Calibration. The safety cable tools should be

stored in a clean, dry place when not in use. Clean any

debris (especially in the crimp cavity in the tool nose)

from the tool with a small brush and solvent if

necessary. Lubricate the tool nose (into the crimp

cavity) with a drop of oil on a regular basis.

Change 2 2-90