TM 1-1500-204-23-6

f.

Safety

Cable

Identification

Stamp.

In

applications where the user requires a logo or ID code to

be a permanent part of the safety cable installation (for

warranty or tractability), it shall be applied by the safety

cable manufacturer to one or more surfaces of the

square end fitting of the safety cable. Only impression

stamping is permitted, no paint, ink or labels are

acceptable. See figure 2-91.

Figure 2-91. Safety Cable Identification Stamp.

g.

Safety Cable on Turnbuckles. The standard

procedure for securing turnbuckles with safety cable is

shown in figures 2-92 and 2-93.

(1)

A self looping safety cable is threaded

through the turnbuckle. One end shall be wrapped in

one direction around the turnbuckle. The safety cable is

then threaded through the hole in the self looping

jumper, and terminated with the appropriate application

tool.

(2)

Safety cable diameter selection for

turnbuckle applications, 0.032 inch diameter safety

cable shall be used on assemblies where cable diameter

is 1/16 inch or smaller, and 0.040 inch diameter safety

cable or greater shall be used on turnbuckle cable

diameters greater than 1/16 inch.

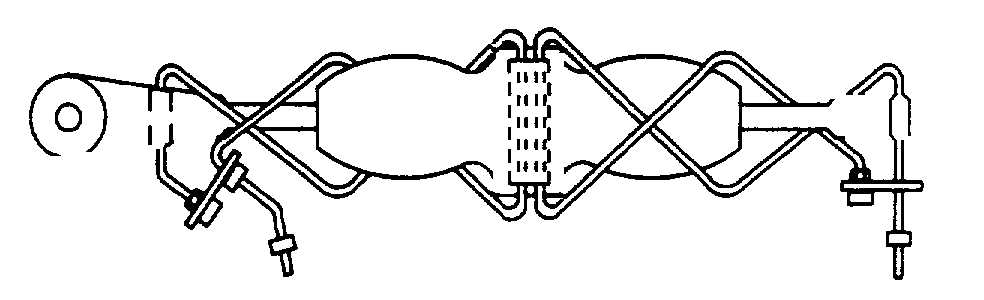

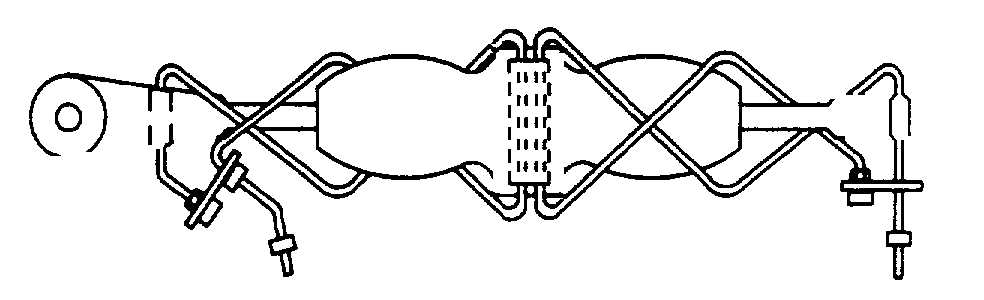

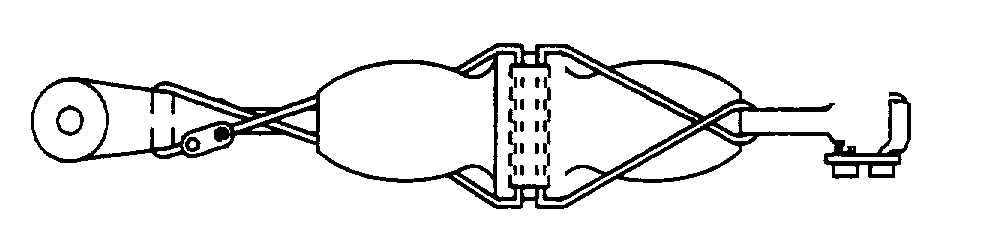

Figure 2-92. Routing of Safety Cable on

Turnbuckles

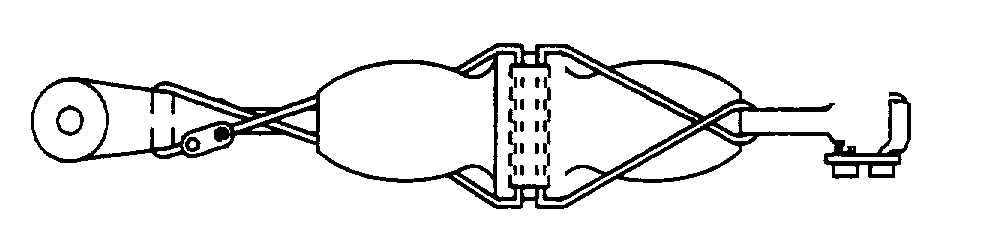

Figure 2-93. Example of Final Safety Cable

Turnbuckle Installation

h.

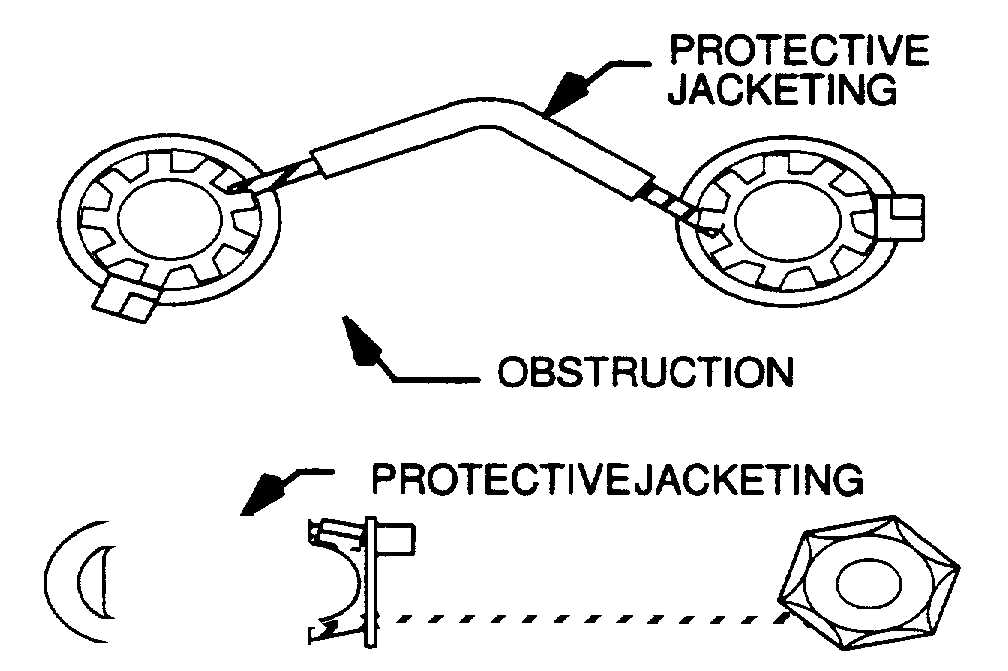

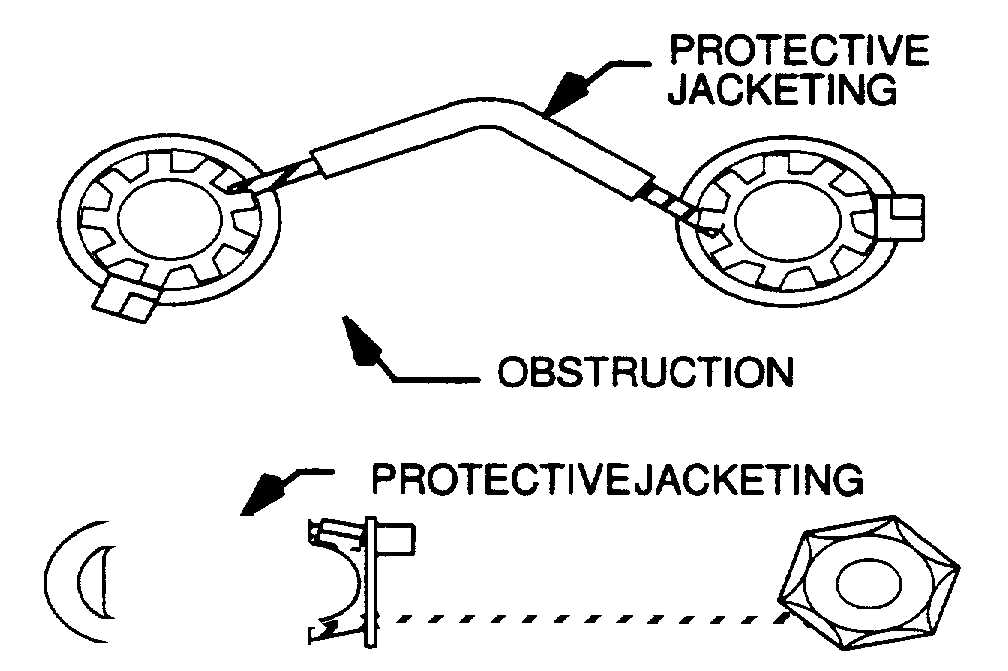

Safety Cable Jacketing for Protection. (See

figure 2-94). It is recommended to use a tubular jacket

over safety cable when it is installed in a location where

it is in contact with (or may contact) surfaces which may

damage the safety cable. A tubular jacket material shall

be capable of meeting the temperature range of the

application, it shall be resistant to oil and chemicals.

Figure 2-94. Cable jacketing for Protection

2-20. Safety Cable Application Tools.

a.

Procedures. When safety cable is used, the

following basics apply for the application tools and

calibration equipment.

(1)

Minimize mixing of safety wire and

safety cable.

(2)

Install the ferrule cartridge into the tool

body under the handle grip.

NOTE

When loading and using the safety

cable hand tool, be certain that the

correct size safety cable kit is being

used with the tool.

(3)

Install the safety cable through the

fasteners to be secured.

(4)

The nose can index to four positions at

90°

increments. To select the position, push the nose in

towards the tool and rotate to the desired position.

Release the nose, if the nose does not lock into the

indexed position, turn it slightly until it does. See figure

2-95.

(5)

Insert the free end of the cable through

the ferrule in the cartridge, and remove the ferrule by

pulling the cable away from the end of the cartridge.

See figure 2-95.

Change 2 2-88