TM 1-1500-204-23-6

c.

Safety Cable Installation. Safety cable may

be used as a substitute for lockwire to prevent loosening

during service. Threaded parts, such as drilled-head

bolts, fillister head screws, turnbuckles, thumbscrews,

hose fittings and electrical connectors, plugs, caps, and

similar items are within the scope of the safety cable

application. The following rules shall apply when using

safety cable.

NOTE

Routing of safety cable may vary from

that of lockwire in order to achieve a

proper installation.

(1)

When safety cable is being substituted

for lockwire in an existing installation (maintenance,

rework, etc.), equivalent diameter safety cable to that of

the lockwire shall be selected for use, providing that

selection criteria for safety cable as defined in the (1)

General Instructions are met.

(2)

Adjacent Units. Safety cable shall be

installed in such a manner that any tendency for a

fastener to loosen will be counteracted by an additional

tension on the cable. Safety cable shall be threaded

through the fasteners in such a way as to produce

installed safety cable with either positive or neutral pull.

(3)

Maximum Span. The maximum span

of safety cable between two termination points shall be

6 inch (152.4 mm) unless otherwise specified.

CAUTION

Installing Defects: Any cable defect

(nick,

fray,

kink,

or

any

other

mutilation of the safety cable) found

prior to, during, or subsequent to

installation, is not acceptable.

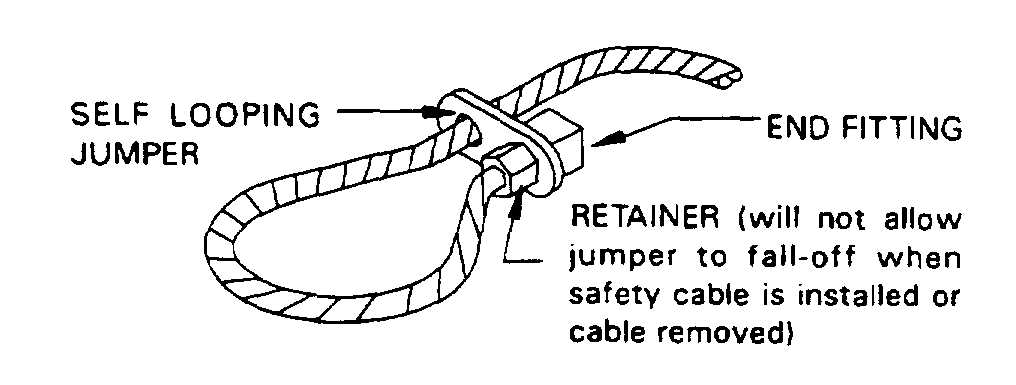

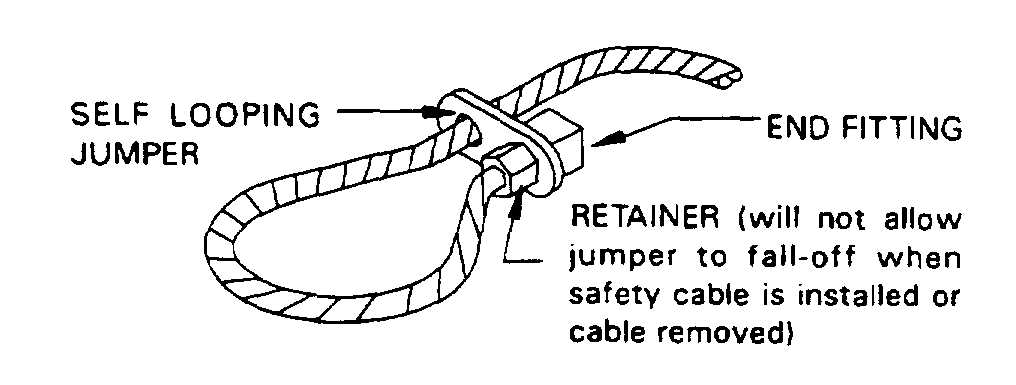

Figure 2-84. Self Looping Safety Cable TM 1-1500-

204-23-6

NOTE

Avoid kinks or sharp bends while

handling and threading safety cable.

(4)

Installing Holes. Safety cable must be

installed through the holes intended for this purpose in

the part being secured, or through the holes provided in

a self looping device secured to the safety cable by the

safety cable manufacturer (figure 2-84). In applications

where holes are not provided for safety cable in the

component to which it is attached the self looping safety

cable may be used in a manner like, or similar to figure

2-85.

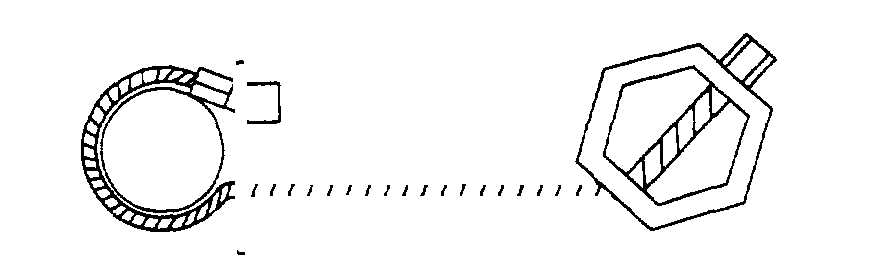

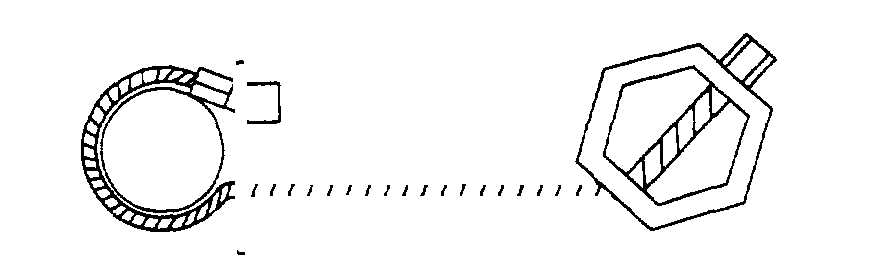

Figure 2-85. Self Looping Safety Cable Anchored to

a Pin Assembly

(5)

Safety Cable/Ferrule Reuse. Safety

cable and ferrule shall be new upon each application.

Reuse is not allowed.

(6)

Installation. Various examples of

safety cable installation are shown in this section. All

possible combinations and applications are not shown.

Unless

otherwise

specified

in

the

application

engineering drawing, safety cable shall be installed in

two or three bolt patterns with two bolt patterns being the

preferred method where an even number of fasteners

are to be secured. The installer must adhere to the

basic rules outlined in this manual.

(7)

Hose Fittings and Electrical Connector

Requirements. Hose fittings and electrical coupling nuts

shall have safety cable installed in the same manner as

tube coupling nuts.

(8)

Excess Cable. After Installing safety

cable, excess cable from the crimped ferrule shall be

cut by the installation tool. The maximum allowable

length of cable extending beyond the ferrule shall be

0.031 inch (0.79 mm).

(9)

Crimping Requirements (Pull-Off Load,

Reference Table 2-19). Safety cable shall be installed

with the safety cable manufacturers recommended tool,

which has been tested and calibrated in accordance with

procedures specified in this manual.

Change 2 2-85