TM 1-1500-204-23-6

Table 2-19. Safety Cable Minimum Crimp

Requirements (Pull-Off Load)

Nominal Cable

Diameter

Inch (mm)

Safety Cable

Construction

Minimum

Pull-Off Load

Ibf (N)

0.020 (0.51)

1 x 7

30 (133.4)

0.032 (0.81)

3 x 7

70 (311.4)

0.040 (1.02)

7 x 7

110 (489.3)

(10) Hole Alignment. Undertorquing or

overtorquing to obtain proper alignment of the holes is

not permitted. Apply recommended torque values to

parts to be secured, and alignment of holes shall be

evaluated before attempting to proceed with safety

cable.

CAUTION

The maximum bend exit limit of

safety cable, when applied to a

threaded fastener head, shall be

1350. This does not apply to hose

fittings, electrical connector coupling

mechanisms,

turnbuckles,

and

similar applications where the safety

cable is constrained by the shape of

the component being secured.

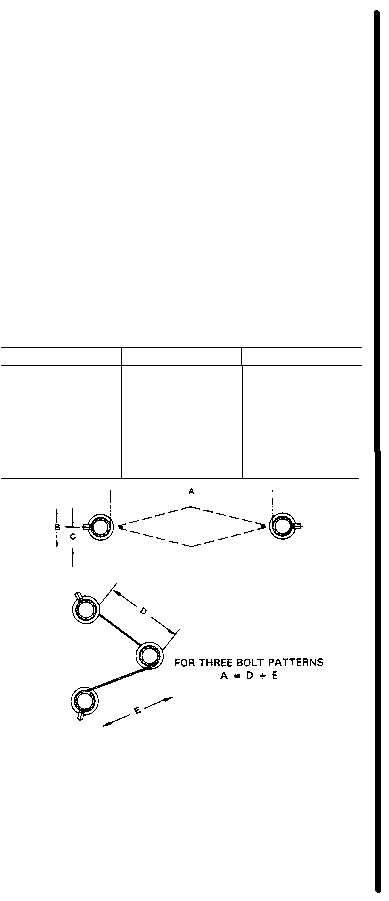

(11) In applications where safety cable shall

be required to exceed the 1350 maximum bend exit limit

in order to achieve neutral to positive pull on a threaded

fastener head, a self looping device which is secured to

the safety cable by the safety cable manufacturer may

be used to obtain a secured installation as shown (figure

2-86).

CAUTION

This method should only be used in

applications where the safety cable

can not "flip" over the corner or over

the head of the fastener being

secured.

Figure 2-86. Self Looping Safety Cable in High

Bend Exit Application

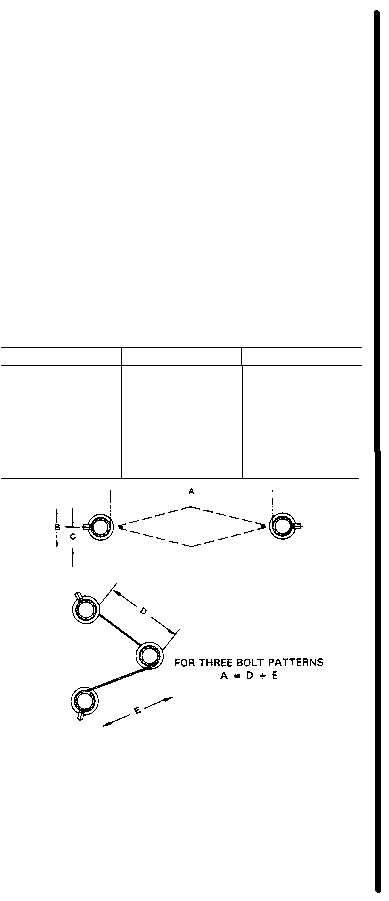

(12) Cable Flex Limits. After installing

safety cable, the maximum flex between termination

points shall be no greater than that specified in the

Cable Flex Limit Table (table 2-20).

NOTE

When calculating the flex limit (B & C)

of safety cable which is installed

through three fasteners, the A = D + E

formula shall apply (see figure 2-87).

The total length of safety cable from the

point where it exits the first fastener, to

the point where it enters the last

fastener shall be measured. The

corresponding length from table 2-20,

column A shall be used to determine the

flex limit.

Table 2-20. Flex Limits, Inch (mm)

A

B

C

0.5 (12.7)

0.125 (3.18)

0.062 (1.59)

1.0 (25.4)

0.250 (6.35)

0.125 (3.18)

2.0 (50.8)

0.375 (9.52)

0.188 (4.76)

3.0 (76.2)

0.375 (9.52)

0.188 (4.76)

4.0 (101.6)

0.500 (12.70)

0.250 (6.35)

5.0 (127.0)

0.500 (12.70)

0.250 (6.35)

6.0 (152.4)

0.625 (15.88)

0.312 (7.94)

Figure 2-87. Safety Cable Flex Limits

NOTE

Light

finger

pressure

of

approximately 2 pounds shall be

applied at mid-span when inspecting

total flex limit of installed safety

cable.

Change 2 2-86