TM 1-1500-204-23-6

(6)

Checking torque. Checking installed

fasteners to determine if they have been tightened to

the specified torque value cannot be accurately

accomplished using a torque wrench. Installed

fasteners generally require more torque than was

originally applied, in order to overcome static friction

and start the fastener turning. To ensure proper torque

has been applied, the fastener should be backed off

from one-half to one full turn and retightened to the

correct torque value. A torque wrench should not be

used for the backoff operation.

(7)

Retorquing.

In

some

special

applications, it is necessary to retorque a fastener after

a prescribed period following initial installation in order

to insure that proper clamping force and bolt tension are

still in effect. If retorquing is required, the applicable

aircraft maintenance manual should be consulted for

proper retorquing procedure.

(8)

Damaged

threads.

Studs

with

damaged threads should be replaced or the threads

rechecked; however, this is not always possible in field

maintenance. To overcome the problem of tightening a

nut on a stud to the proper torque value where thread

damage is present and therefore increases the rundown

resistance of the nut, add the rundown resistance to the

specified torque value. The rundown resistance should

be measured on the last rotation before the nut seats.

For example, if 325 inch-pounds of torque is specified

for an application and the rundown resistance due to

thread damage is 25 inch-pounds, the nut should be

tightened to a torque of 325 inch-pounds plus 25 inch-

pounds, or 350.

c. Recommended

Torque

Values.

For

recommended torque values, refer to tables 2-8 and 2-9.

2-19. Safety Cable.

a.

General Instructions for the Selection of

Safety Cable. The selection of materials shall be in

accordance with AS4536 (SAE), available from SAE

International, 400 Commonwealth Avenue, Warrendale,

PA 15096-0001, and shall be in accordance with the

service limitations outlined herein.

NOTE

Minimize mixing of safety wire and

safety cable.

(1)

AS3510 series (UNS S32100 CRES)

safety cable shall be selected for general purpose use

on all applications up to 649 °C (1200°F).

(2)

AS3509 series (UNS N6600 Nickel

Alloy) safety cable shall be selected for up to 9820C

(18000 F).

(3)

Only

safety

cables

and

ferrules

supplied by a manufacturer that meets all the

requirements of AS4536 shall be allowed.

(4)

Safety cable shall not be used for any

shear, or break away applications.

(5)

Safety cable shall be installed with a

calibrated tool which is supplied by the safety cable

manufacturer

for

the

purpose

of

applying

a

predetermined cable tension, crimping the ferrule, and

cutting the excess cable without allowing tension to be

lost.

b.

The Size of Safety Cable Shall be in

Accordance with the Following Requirements:

(1)

0.020 inch diameter safety cable is

intended for use on parts having a nominal hole

diameter of 0.045 inch (1.14 mm) or smaller.

(2)

0.032 inch diameter safety cable is

intended for use on parts having a nominal hole

diameter of 0.075 inch (1.91 mm) or smaller.

(3)

0.040 inch diameter safety cable is

intended for use on parts having a nominal hole

diameter of 0.095 inch (2.41 mm) or smaller.

(4)

The specified length of the cable shall

be selected to accommodate the span between

fasteners added to the length of cable required to

correctly engage the application tool.

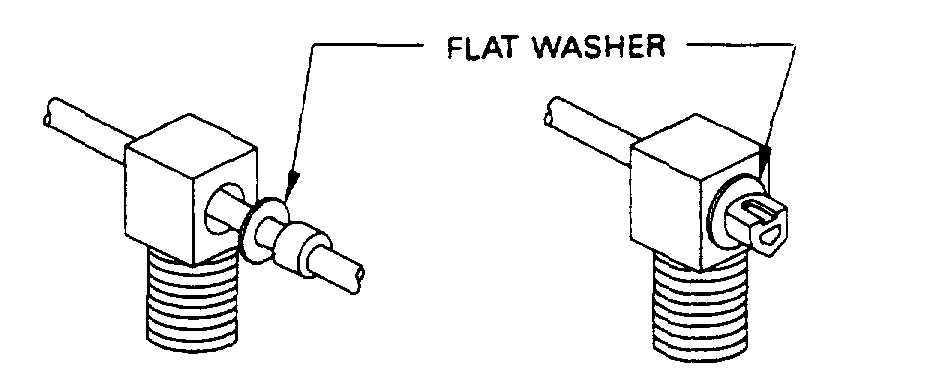

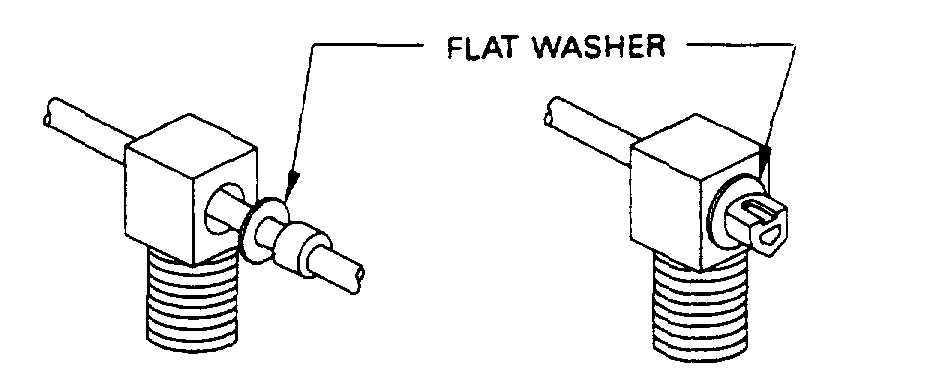

(5)

Applications where safety cable is to be

installed through a hole having a nominal diameter of

greater than 0.095 inch (2.41 mm), but less than 0.200

inch (5.08 mm) shall require a flat washer (same

material composition as the safety cable) which is

supplied by the manufacturer for this purpose, and shall

be used as shown in figure 2-83.

Figure 2-83. Flat Washer Safety Cable Installation

(FW10-1)

(6)

Safety cable shall be installed with an

application tool which has been calibrated to meet the

performance requirements of AS4536 (SAE) and this

manual.

Change 2 2-84