TM 1-1500-204-23-9

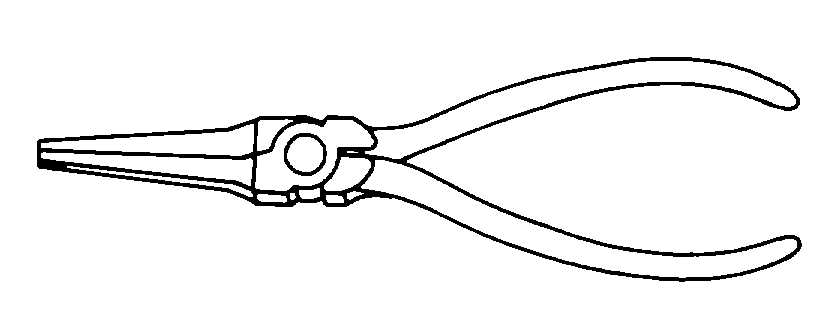

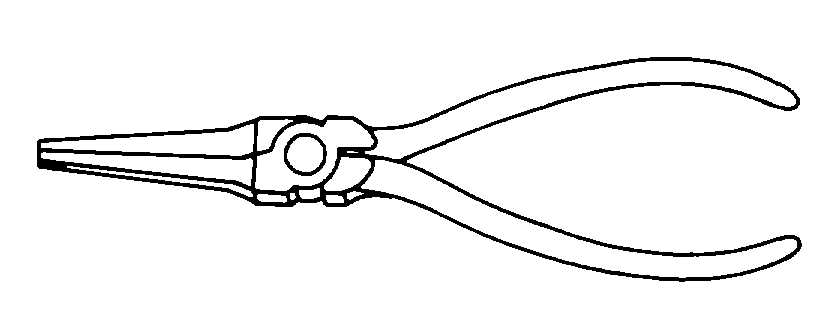

Figure 4-44. Flat-Nose Pliers

(5)

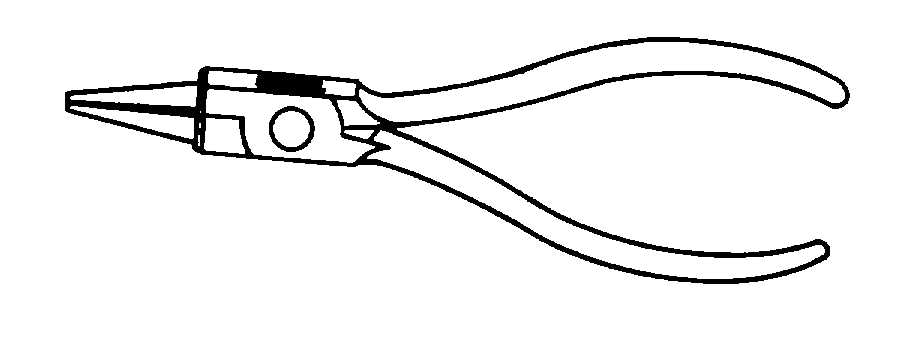

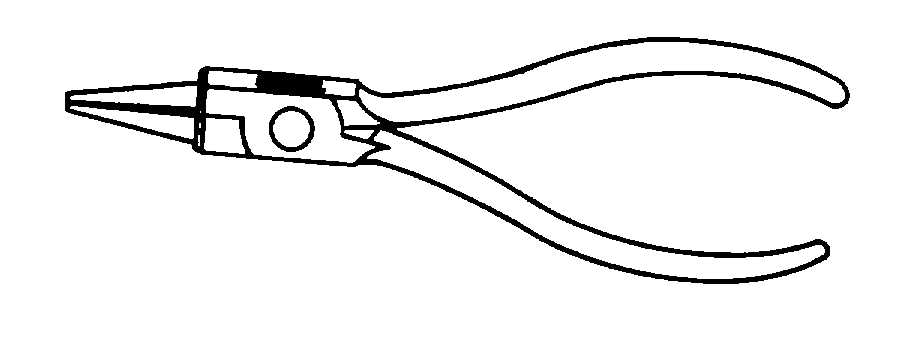

Round-nose pliers. The round-nose pliers

are used to crimp flanges on sheet metal in the process

of shrinking, and for making loops in soft wire. It has

smooth, round jaws, a fixed pivot, and curved handles

which may have insulated sleeves. It is shown in figure

4-45.

(6)

Crimping pliers. Crimping pliers have

practically the same design as ordinary round-nose

pliers. Because a crimp in sheet metal is made by

twisting rather than clamping, they are constructed of

heavier material to withstand heavy side loads induced

by the twisting motion.

(7)

Water pump pliers. Water pump pliers,

sometimes referred to as channel lock pliers, are used

for their powerful grip and ability to adjust to several

different sizes. As figure 4-46 shows, there are two

adjustment methods used with this type of pliers.

(8)

Vise-grip pliers. Vise-grip pliers have a

clamping action which allows them to be clamped onto

an object. They will stay there and free the other hand

for other work. These pliers, shown in figure 4-47, are

sometimes made with a clamp-type jaw which allows

them to be used for clamping sheet metal. The vise-

grip pliers can be adjusted by turning the knurled

adjustment screw until the desired jaw dimension is

reached.

NOTE

Vise-grip pliers should be used with care

since the teeth in the jaws tend to

damage the object on which they are

clamped. Do not use them on nuts, bolts,

tube fittings, or other objects which must

be reused.

b.

Use. Pliers come in various sizes and should

be selected according to the job being performed. They

should never be used as a substitute for a wrench,

because this practice batters nut and jaw serrations

unnecessarily. Although there are several uses for

pliers, they are not an all-purpose tool and should not be

used as a pry bar or for hammering.

Figure 4-45. Round-Nose Pliers

c.

Repair. Generally speaking, repair of pliers is

limited to grinding or filing cutting or holding surfaces.

Further repair of pliers is usually impractical when

compared with the replacement cost.

(1)

Grinding. It is possible to grind or sharpen

some types of side cutting pliers. However, they should

be examined closely to see if they still close properly

after the material is ground away from the cutting edges.

Do not attempt to grind pliers not designed to be ground.

Grind

cutting

edges

so

that

ground

bevel

is

approximately at right angles to inside machined bevel.

Grind sparingly, and remove the same amount of stock

from both jaws. Cool often in water to preserve temper.

(2)

Renewing serrations. Jaw face serrations

may be renewed by placing pliers in a vise and renewing

serrations with a 4-or 5-inch, three-cornered file.

d.

Care. Observe the following practices for the

care and upkeep of pliers:

(1)

Remove dirt and grease with a clean rag

and apply a light coat of oil after each use.

(2)

Store pliers in a tool box or hang on racks

when not in use.

(3)

Do not remove insulation on handles or oil

handles which are insulated.

(4)

Do not use pliers for prying or for

removing nuts or bolts.

(5)

Replace all pliers which have broken

jaws, handles, or cutting edges.

4-6. Awls. Awls are used in aircraft maintenance to

align holes, as in the installation of a deicer boot, and to

place scribe marks on metal and plastic surfaces. A

typical awl is shown in figure 4-48.

4-15