TM 1-1500-204-23-9

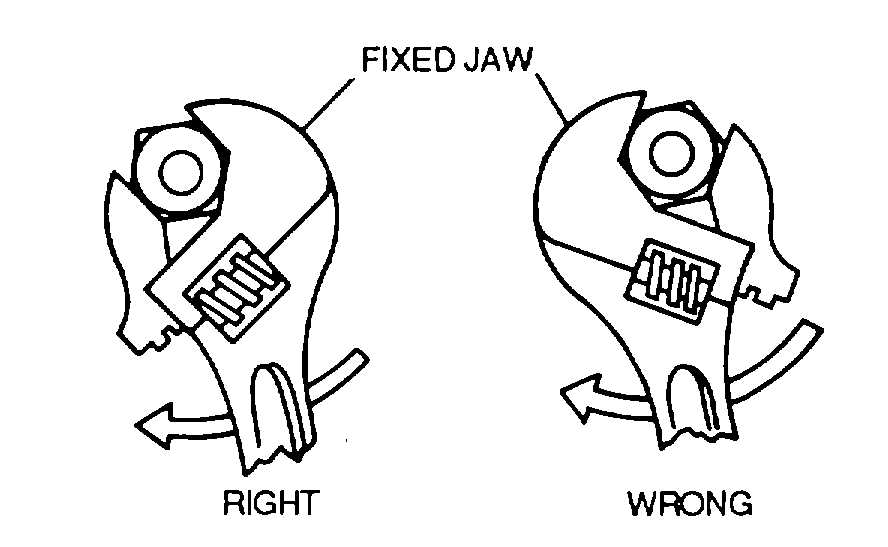

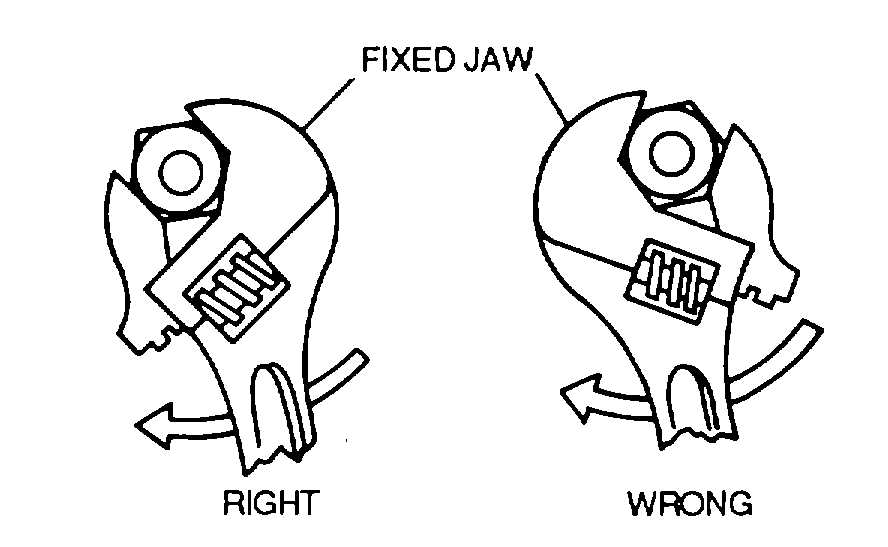

Figure 4-35. Proper Procedure for Pulling

Adjustable wrenches

wrenches is impractical when compared with the

replacement cost.

d.

Care. Observe the following practices for the

care and upkeep of wrenches:

(1)

Clean all wrenches after each use.

(2)

Wrenches that come in sets should be

returned to their cases after use.

(3)

Apply a thin film of oil to the metal parts

of all wrenches before storing them.

(4)

For long-term storage, the wrenches

should be covered with a rust-preventive compound and

carefully stored in a dry place.

e.

Spanner Wrenches. Many special nuts used in

propeller systems are made with notches or holes cut

into the outer edge or the face of the nut. These nuts

are designed to be driven with spanner wrenches.

a.

Types. Spanner wrenches can generally be

classified as one of two types: solid and adjustable.

(1)

Solid spanner wrenches. The following

paragraphs describe the various types of solid spanner

wrenches.

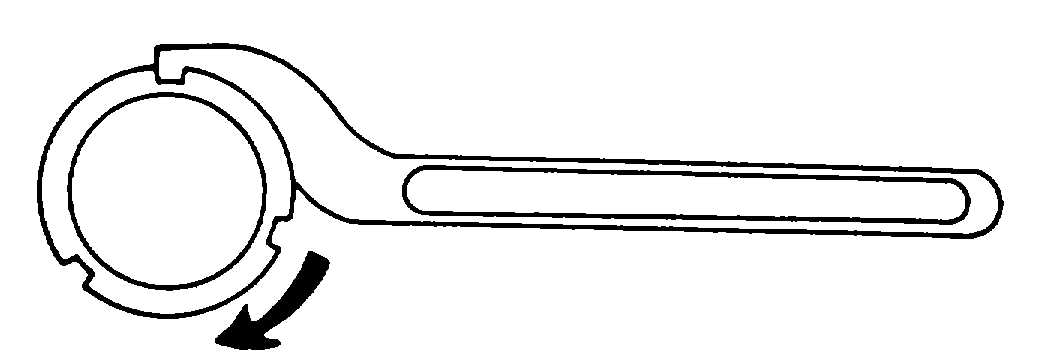

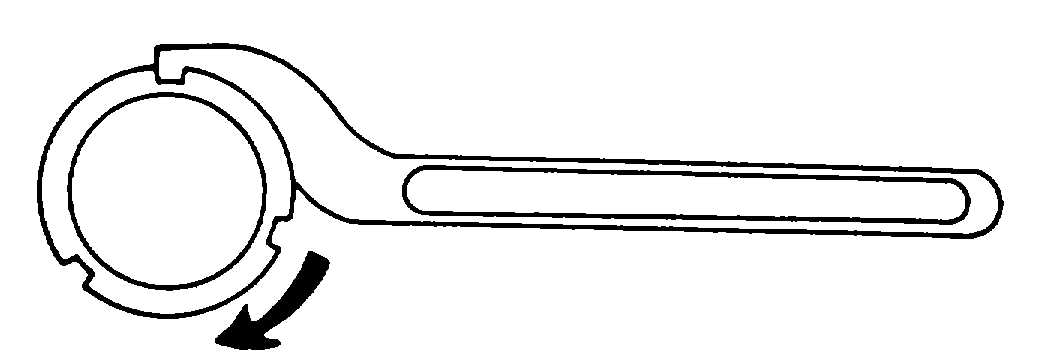

(a)

Hook spanner. Nuts with notches cut

into the outer edge are driven with the hook spanner, as

shown in figure 4-36. This wrench has a curved arm

with a lug or hook in the end. This lug fits into one of

the notches of the nut, and the handle is pulled to

tighten or loosen the nut.

Figure 4-36. Hook Spanner Wrench

(b)

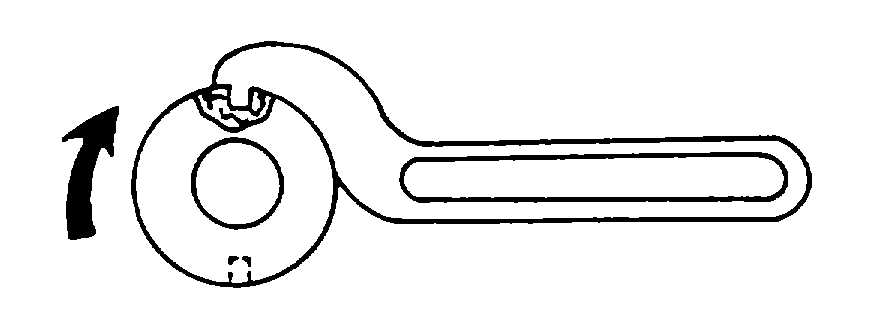

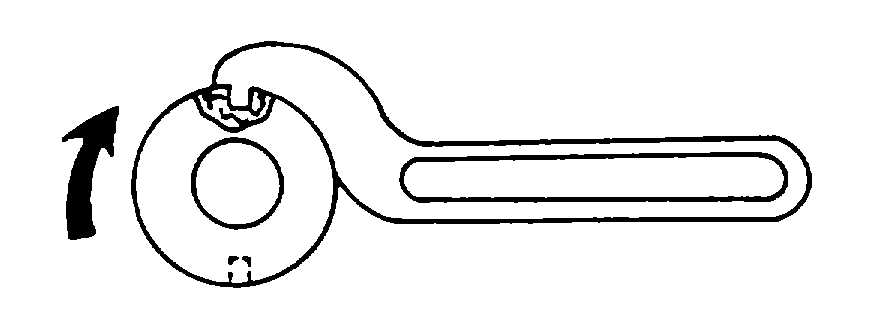

Pin spanner. The pin spanner,

shown in figure 4-37, has a pin in place of the hook.

This pin fits into a hole on the outer edge of the nut.

Figure 4-37. Pin Spanner Wrench

(c)

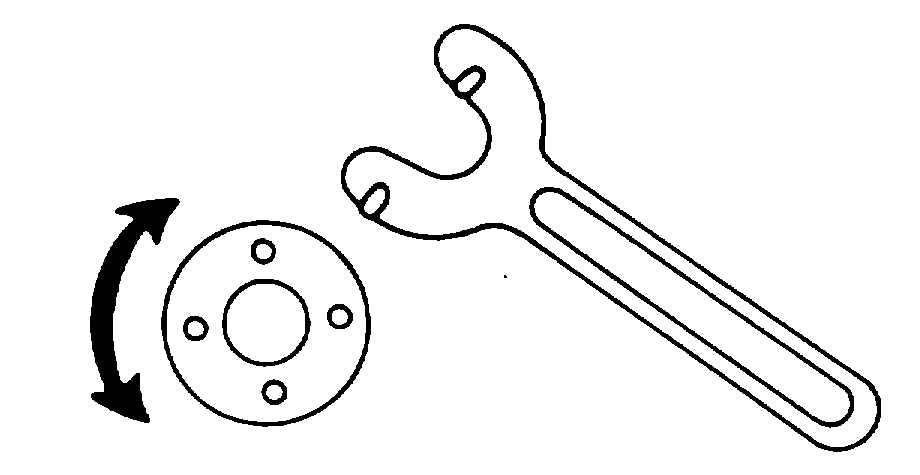

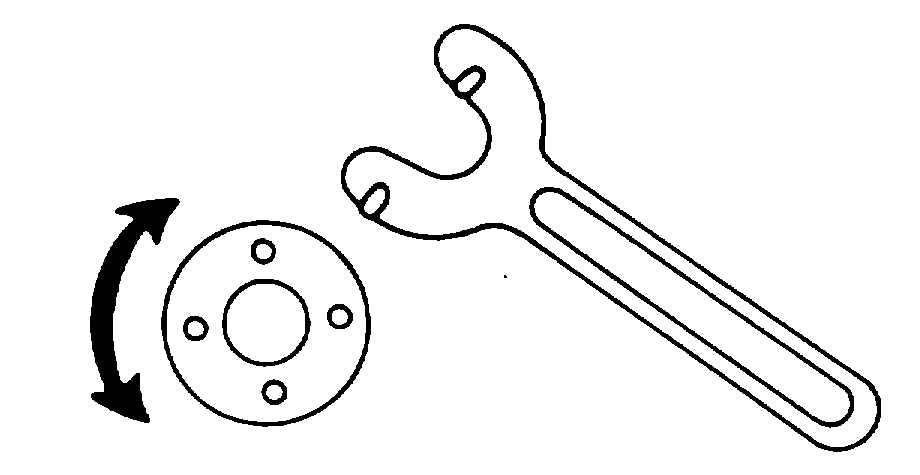

Face pin spanner.

Face

pin

spanners are designed so that the pins fit into holes in

the face of the nut, as shown in figure 4-38.

Figure 4-38. Face Pin Spanner Wrench

(2)

Adjustable

spanner

wrench.

Solid

spanner wrenches are sized for specific sizes of nuts.

The adjustable spanner wrench, shown in figure 4-39,

has a pivoting end which allows the wrench to fit several

nut sizes. The type of wrench shown is a hook spanner,

and is used the same way as the solid hook spanner.

(3)

Pliers, Retaining Ring. The retaining ring

pliers (snap ring) are used to remove internal and

external retaining rings. It is shown in figure 4-40.

4-13