TM 1-1500-204-23-9

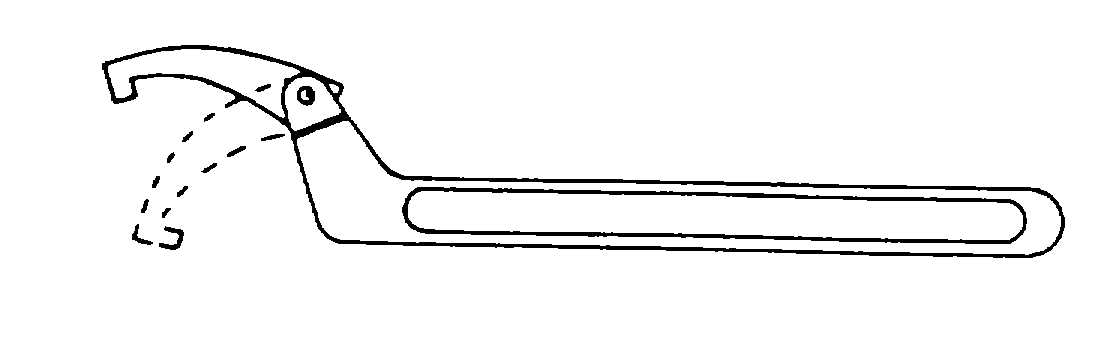

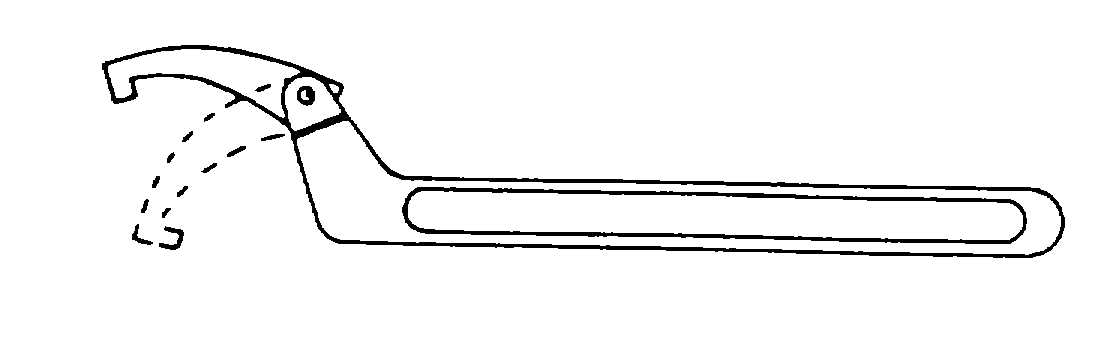

Figure 4-39. Adjustable Hook Spannner Wrench

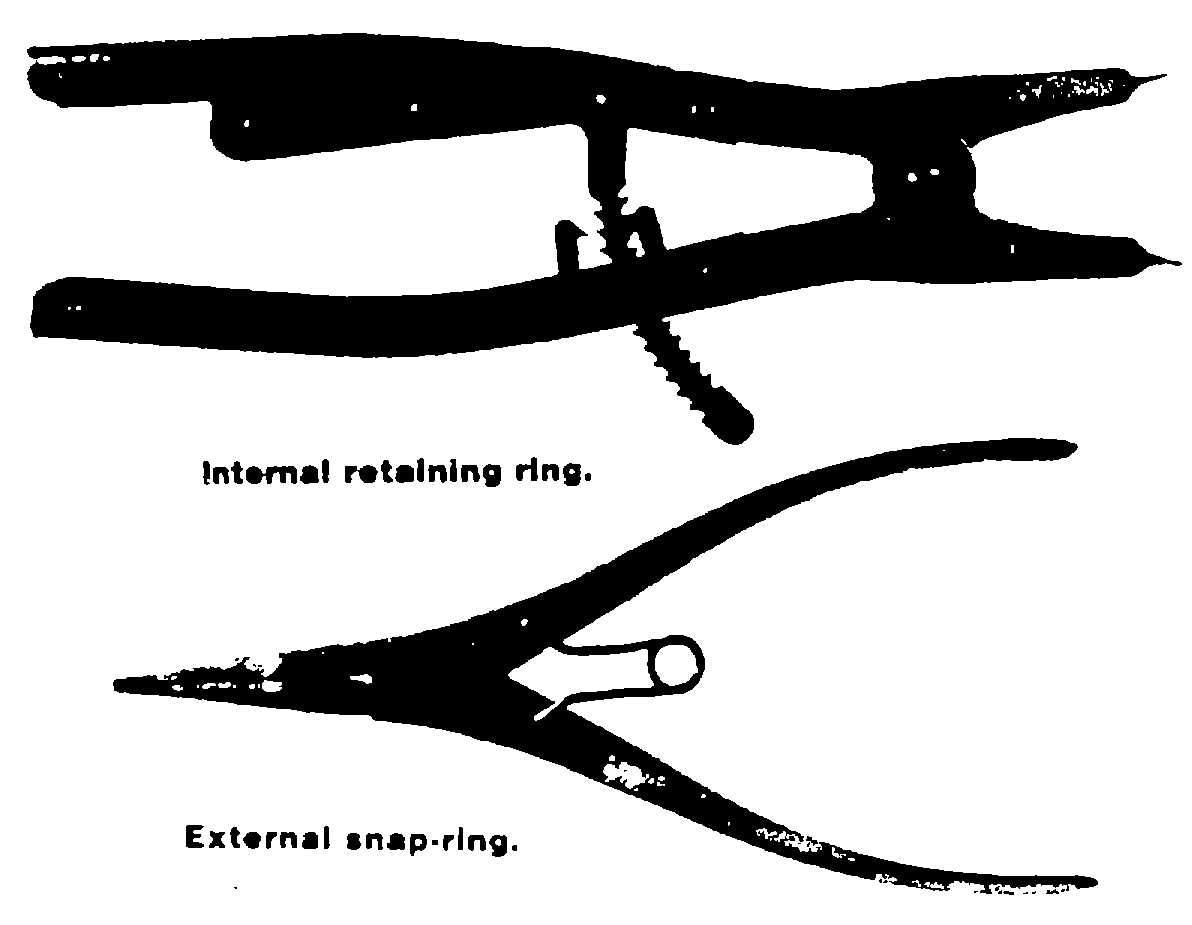

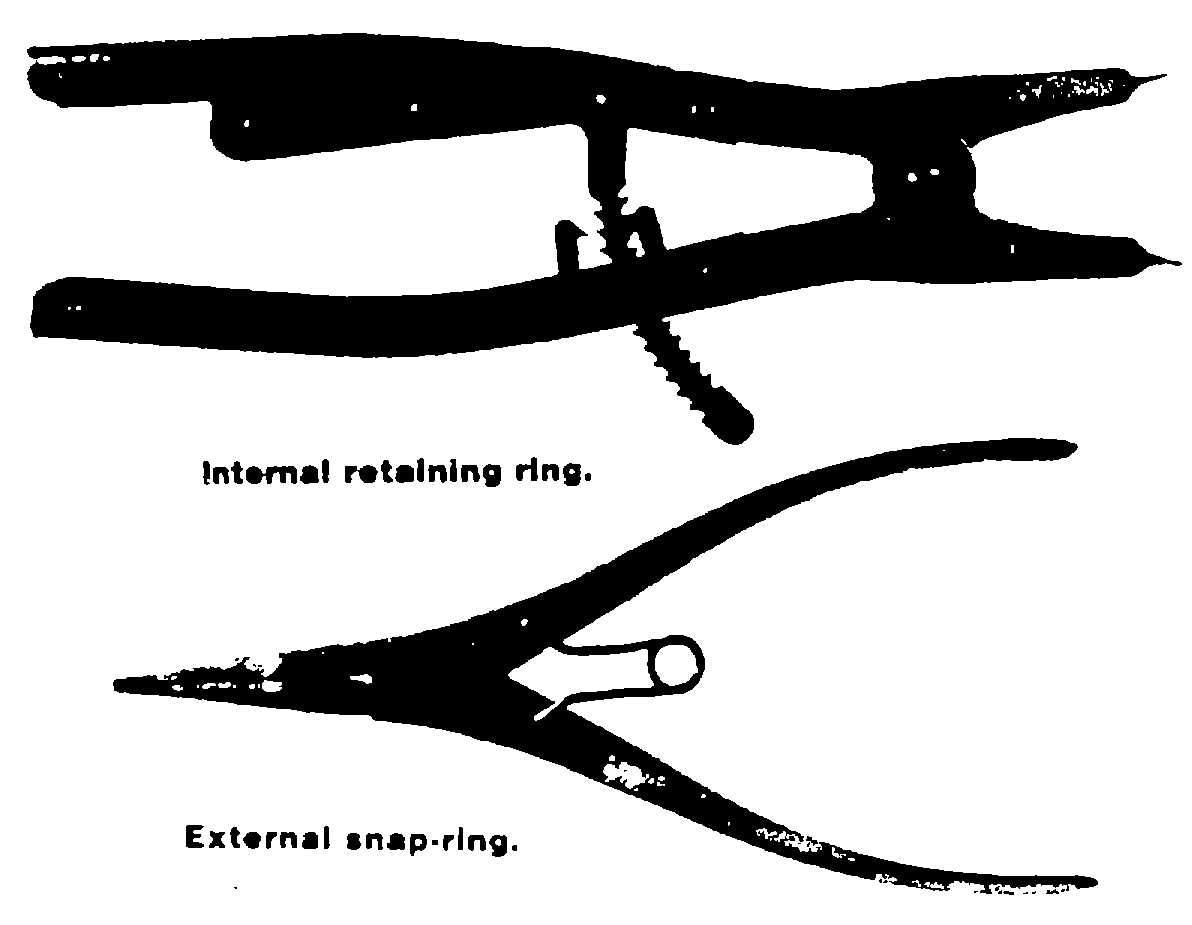

Figure 4-40. Pliers, Retaining Ring

4-5. Pliers. Pliers are so constructed that a force or

pressure applied to the handles is intensified through the

pivot point to the jaws. This leverage enables the

mechanic to hold materials which the hand alone is not

strong enough to hold.

a.

Types. Pliers are made in various types for

various uses. The more common types and their uses

are listed in the following paragraphs:

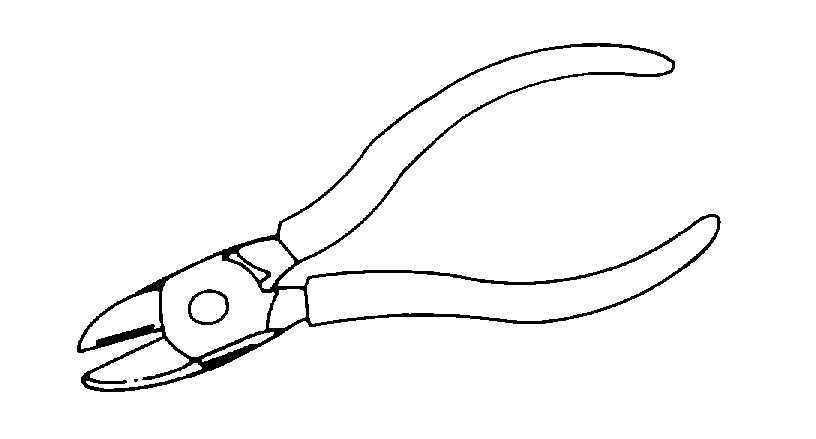

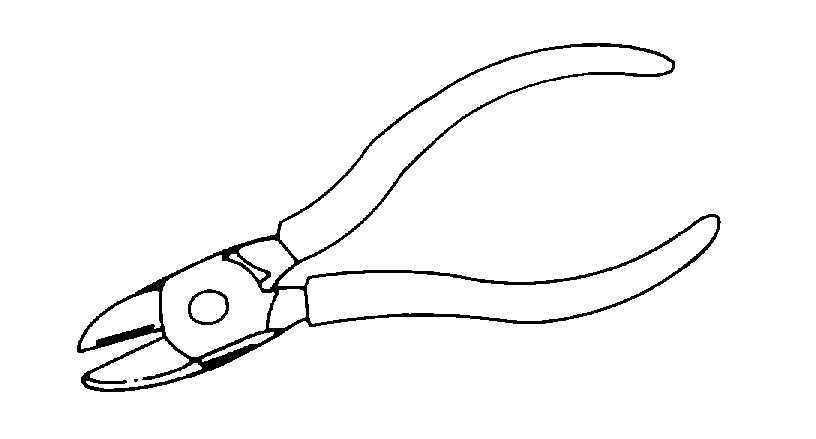

(1)

Slip-joint pliers. The slip-joint combination

pliers shown in figure 4-41 have serrated (grooved)

jaws, with a rod-gripping section, a cutting edge, and a

pivot. The serrated jaws and rod-gripping section are

used to hold objects. The cutting edge permits the

cutting of soft wire and nails. However, cutting hard

materials or large gauge wire will spring the jaws,

making the pliers useless. The pivot is used to adjust

the jaw opening to handle large or small objects.

(2)

Diagonal cutting pliers. The diagonal

cutting pliers, shown in figure 4-42, have a fixed pivot.

The jaws are offset by about 15-degrees and are shaped

to give enough knuckle clearance while making flush

cuts. The diagonal cutting pliers are used for cutting

small, light objects such as wire, cotter pins, and similar

items. These pliers are not to be used to hold or grip

objects.

(3)

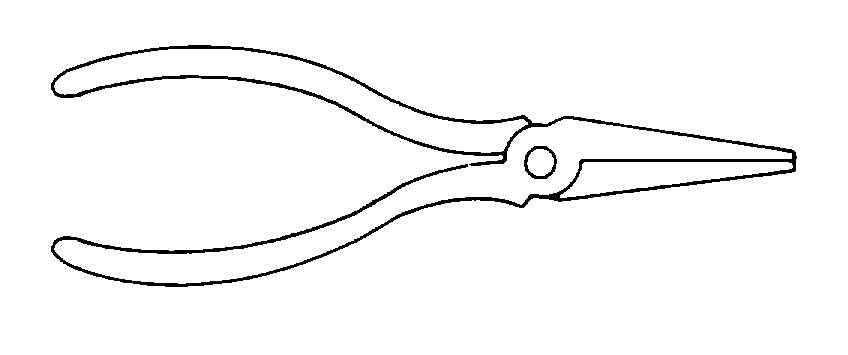

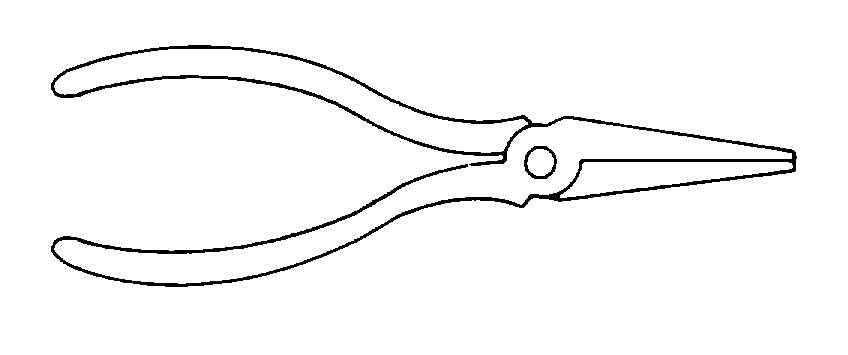

Long-nose pliers. Long nose pliers,

shown in figure 4-43, are used to reach places

inaccessible to the fingers, such as inserting cotter pins

in close places. They are also used to bend small

pieces of metal.

(4)

Flat-nose pliers. The flat-nose pliers have

flat serrated jaws, a fixed pivot, and curved handles

which may have insulated sleeved. These pliers are

used to bend light sheet metal and wire, and are shown

in figure 4-44.

Figure 4-41. Slip-Joint Pliers

Figure 4-42. Diagonal Cutting Pliers

Figure 4-43. Long-Nose Pliers

4-14