TM 1-1500-204-23-9

CAUTION

Install brass or copper caps on the vise

jaws to prevent scratching and denting

of soft substances when clamping.

Highly

polished

surfaces

may

be

protected by pieces of rawhide or

leather.

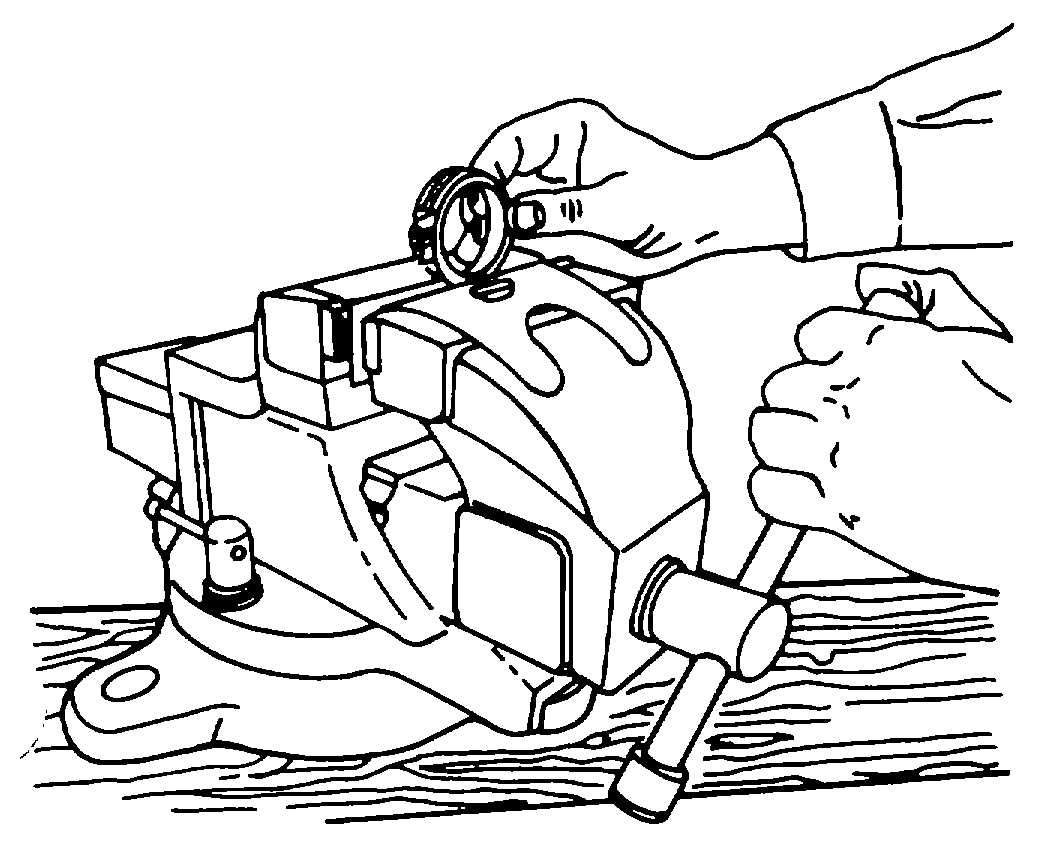

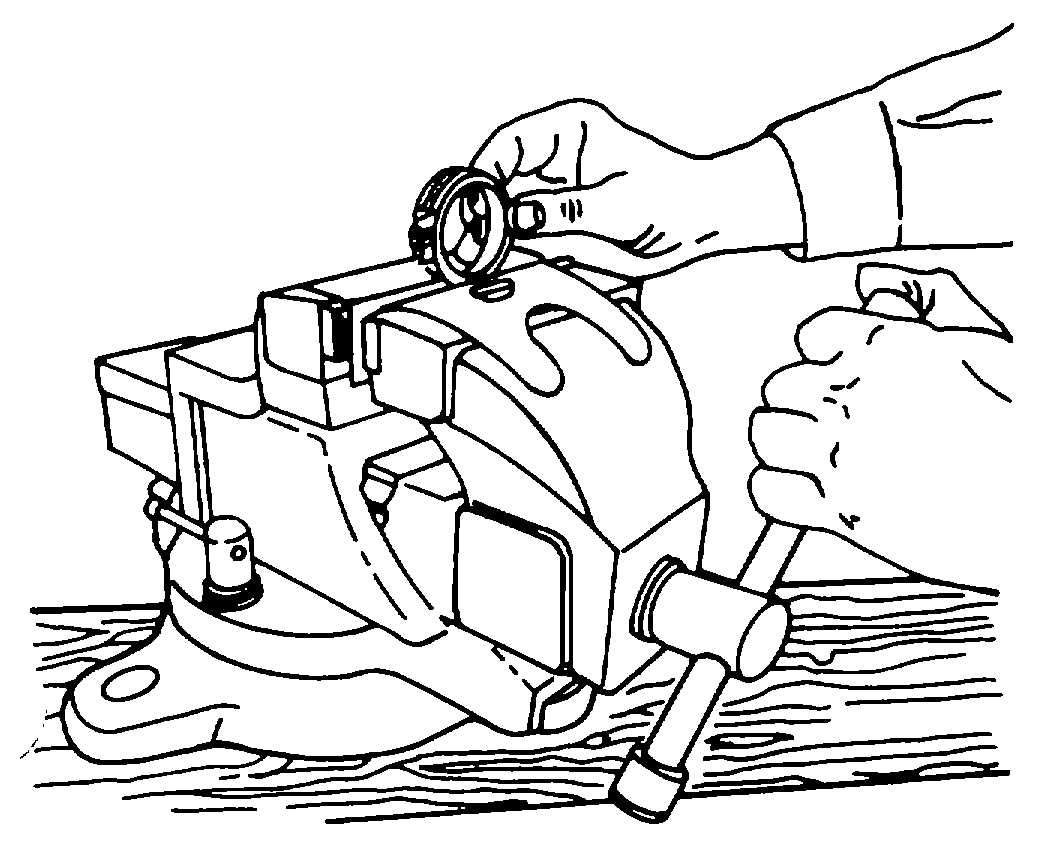

(b)

Insert the object to be clamped between the

vise jaws, and tighten the jaws by turning the handle, as

shown in figure 4-54.

Figure 4-54. Using a Bench Vise

NOTE

Work should be held firmly in place, but

the jaws should not be so tight that they

mar the finish.

(2)

Care. Observe the following practices for the

care and upkeep of bench vises:

(a)

Clean with a rag after each use, and apply

a light coat of oil.

(b)

Keep the jaws in good condition.

(c)

Never oil the swivel base or the swivel

joint, because this decreases its holding power.

(d)

When not using a vise, bring the jaws

lightly together and leave the handle in a vertical

position. This will protect the jaws.

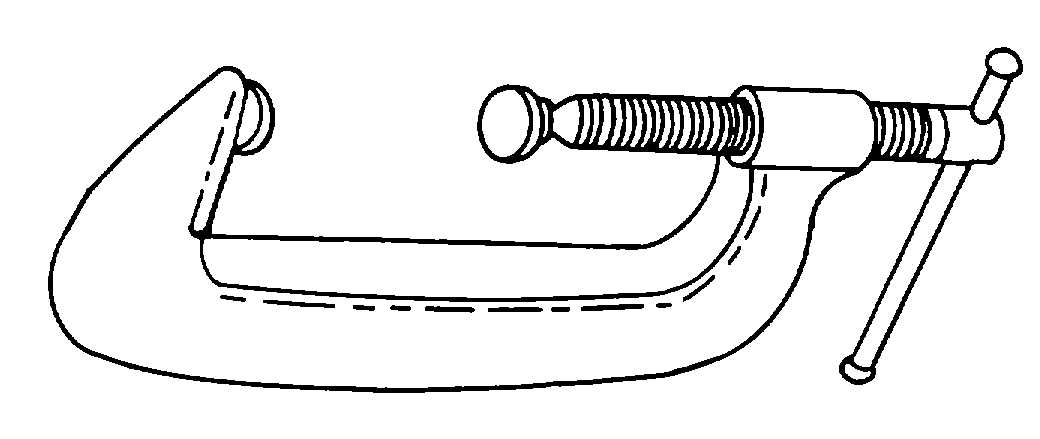

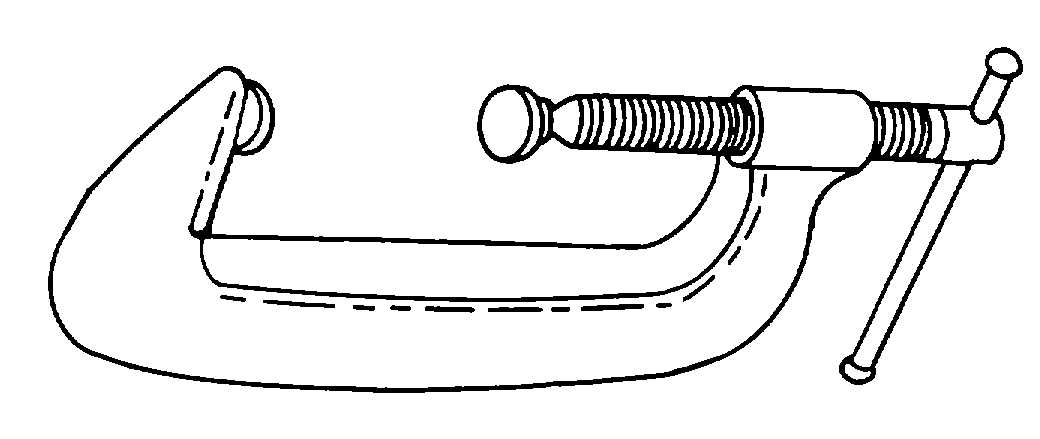

b.

Carriage

Clamps.

The

carriage

clamp,

commonly called a C-clamp, is constructed in the shape

of a large C, as shown in figure 4-55. It is tightened by

use of a screw threaded through one of the bars and has

a swivel plate to prevent the end of the screw from

turning against the item being clamped. C-clamps are

used to hold work which cannot be held in a vise, or

which has to be held for an extended period of time.

They are available in a variety of sizes.

Figure 4-55. Carriage Clamp

(1)

Use. The following paragraphs contain general

procedures for the use of C-clamps:

(a)

Select a clamp which has an opening

about 1 1/2 to 2 inches wider than the object to be

clamped.

(b)

Open clamp as wide as it will go.

CAUTION

Some items, such as glass and highly

polished objects, must be protected to

prevent localized stress and damage.

Use brass shims or wooden blocks to

provide this protection.

(c)

Align the work and the protective shims (if

required).

(d)

As shown in figure 4-56, place the clamp

in position, and tighten the operating screw until contact

is made with the item being clamped.

NOTE

The above procedure should only obtain

a very light contact with the item.

(e)

Check the alignment of the item being

clamped. Ensure that the clamp is applying even

pressure over the entire surface.

4-19