TM 1-1500-204-23-9

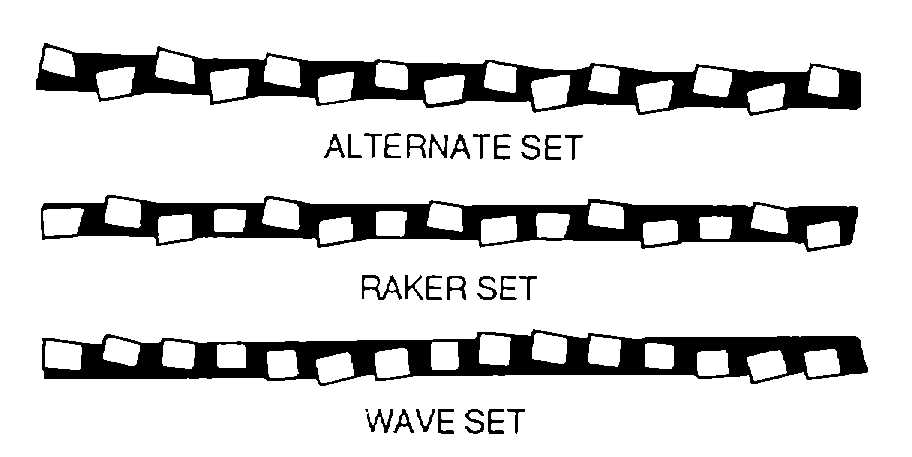

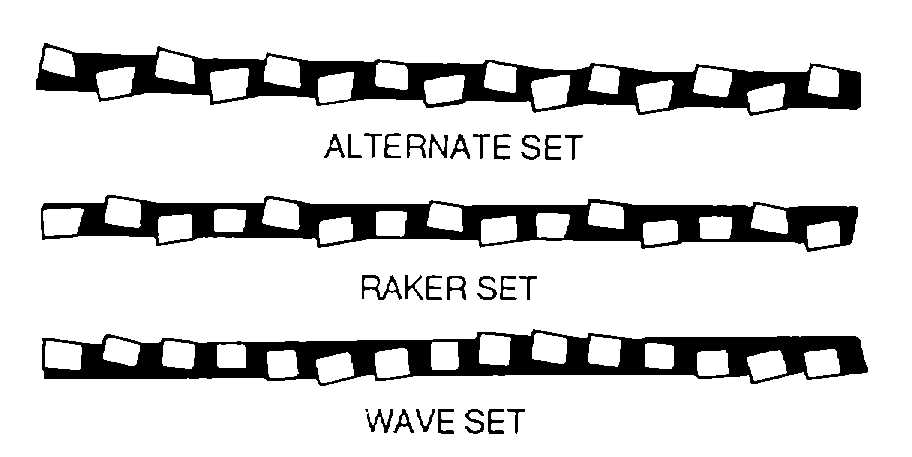

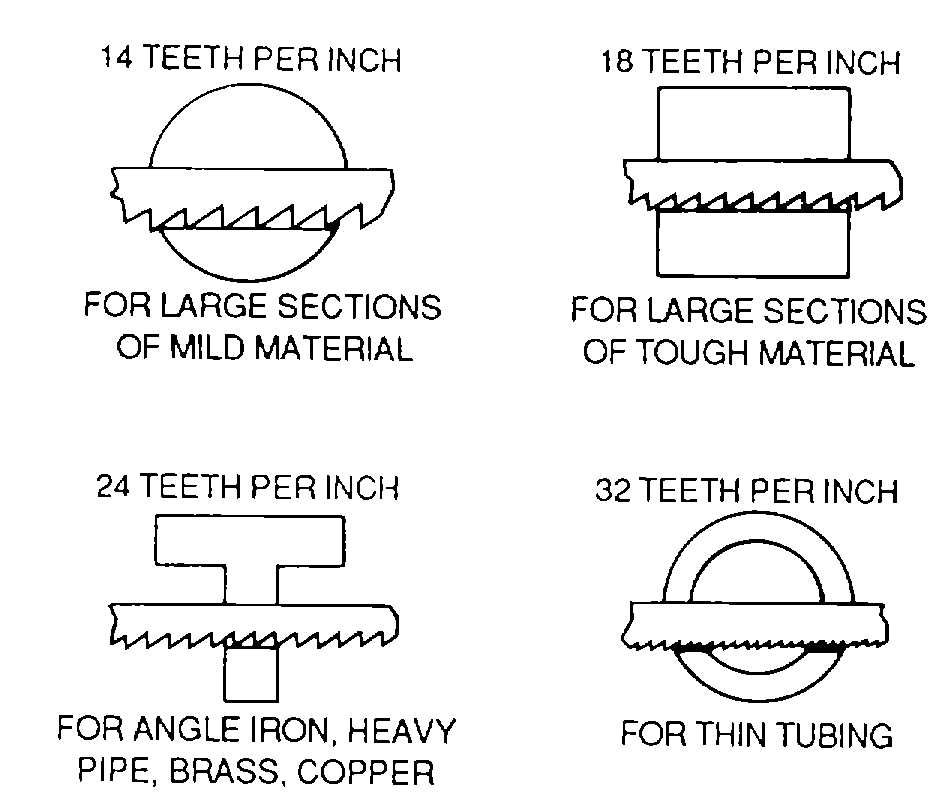

Figure 4-97. Hacksaw Blade Set

(1)

Stock thickness. Heavy stock is usually

cut with the all-hard blade because it has less tendency

to wander. The flexible blade is less likely to break and

is used for thin stock.

(2)

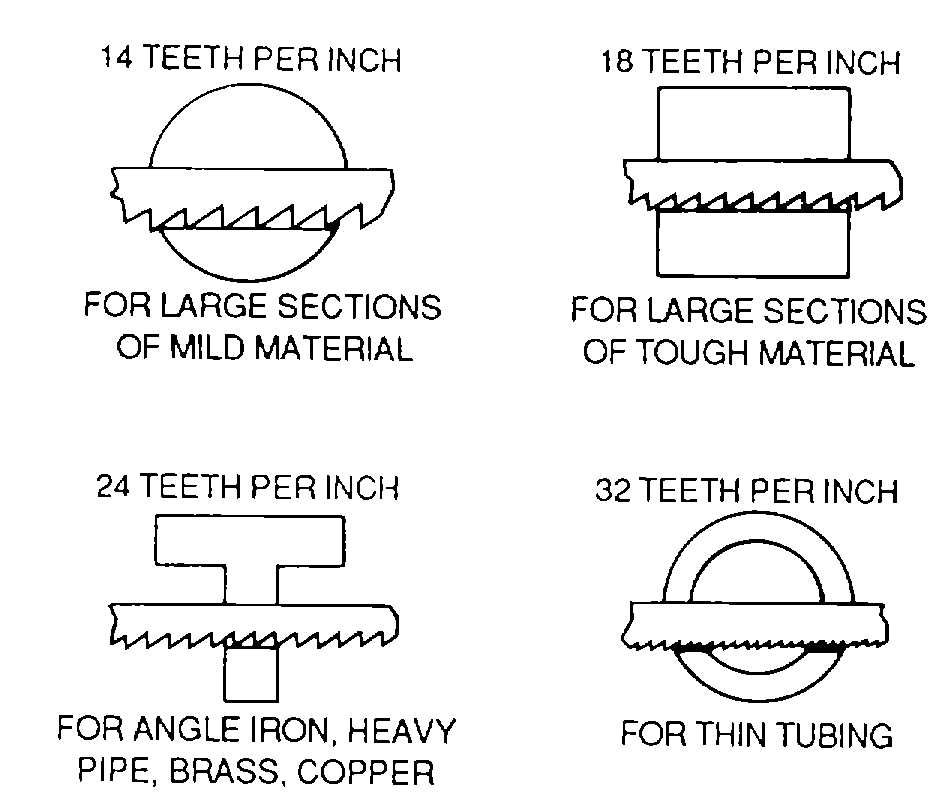

Stock hardness. Generally speaking, the

pitch of the blade depends on the hardness of the stock.

Figure 4-98 shows the typical applications for the

different saw blade pitches.

NOTE

When cutting any stock, there should

always be at least two teeth working on

the stock. Therefore, for thin-walled

stock, a finer blade than that ordinarily

used may be necessary.

Figure 4-98. Application of Blade Pitch for

Certain Materials

c.

Use. The following paragraphs provide

general procedures for the use of hacksaws:

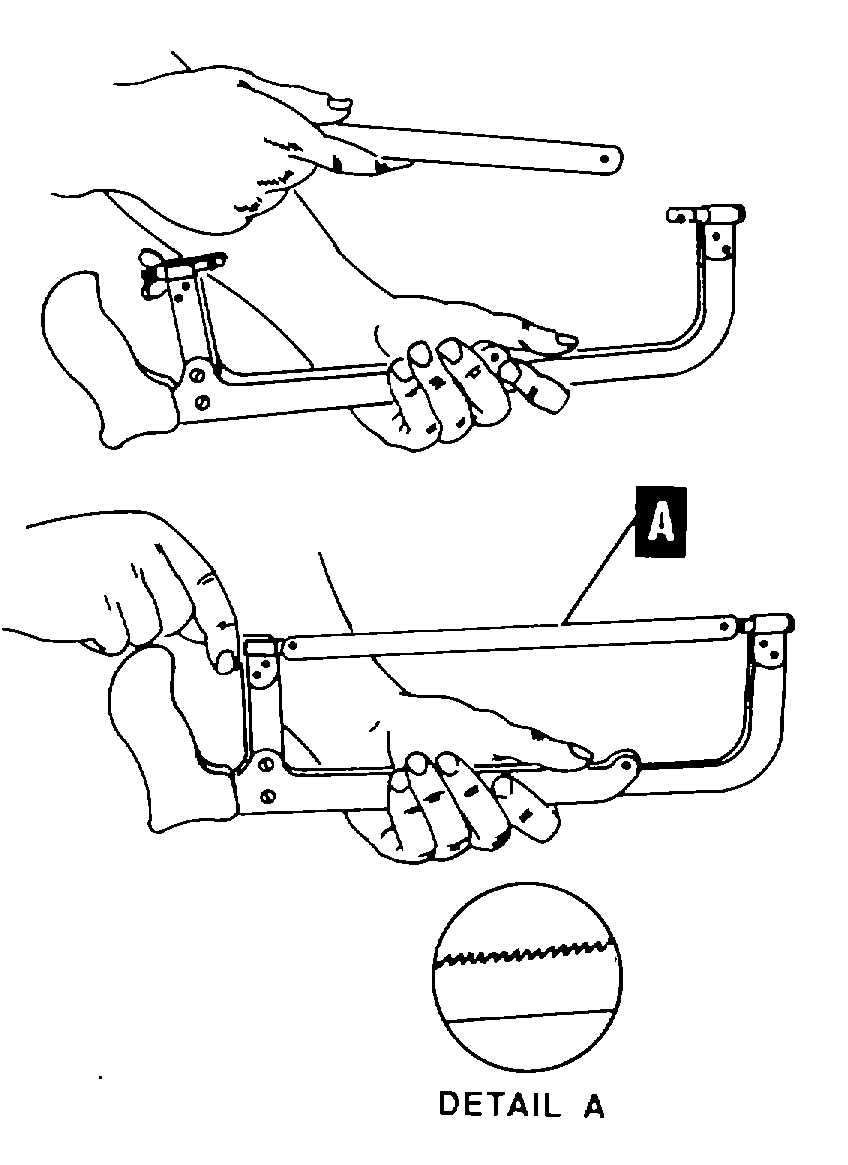

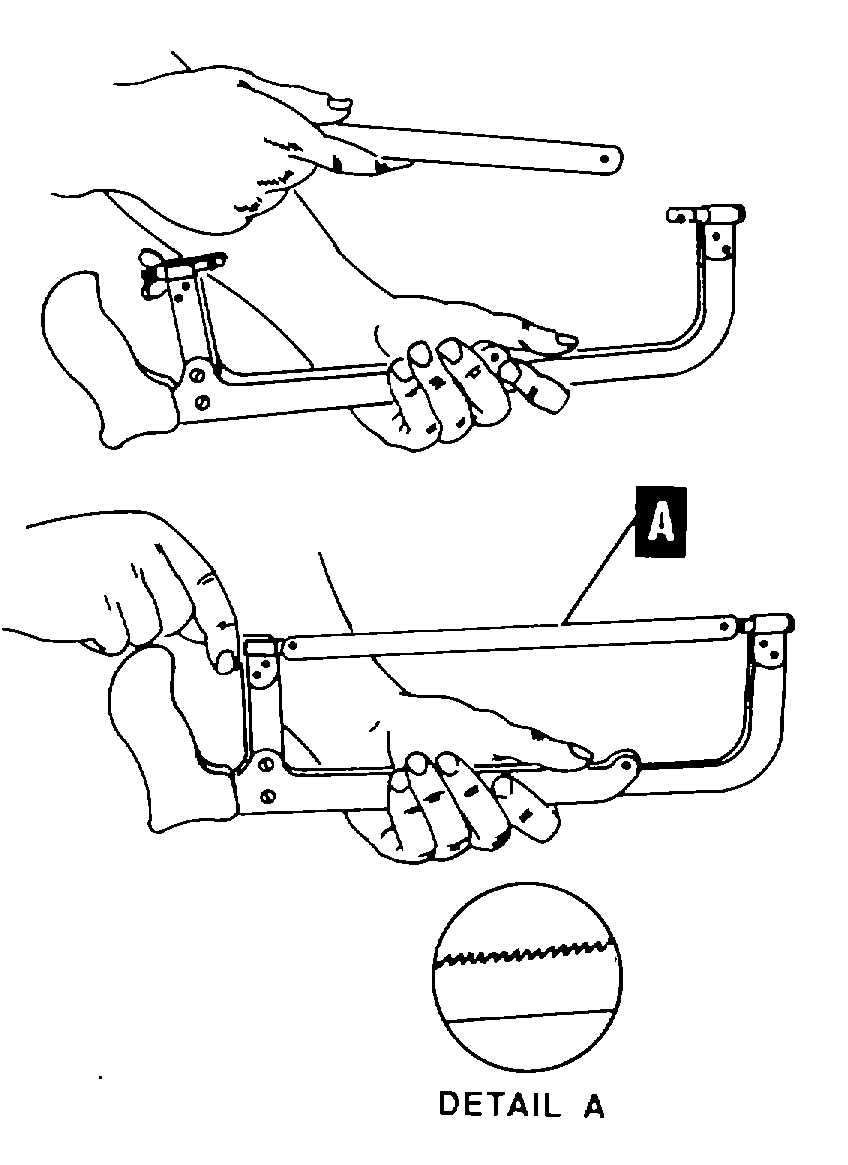

(1)

Install the blade in the hacksaw frame as

shown in figure 4-99. Ensure that the teeth point away

from the handle. Tighten the wing nut so that the blade

is under tension.

Figure 4-99. Installing a Hacksaw Blade

(2)

Place the stock to be cut in a vise.

Maintain a minimum of overhang to reduce vibration,

give a better cut, and lengthen the life of the blade.

Ensure that the layout line on the stock is outside of the

vise jaw so that the line is visible during sawing.

(3)

Hold the hacksaw as shown in figure 4-

100.

(4)

When cutting, apply pressure on the

forward stroke, which is the cutting stroke. Do not apply

pressure on the return stroke. Use long and smooth

strokes. Do not exceed 60 strokes per minute.

4-18. Taps and Dies. Taps and dies are made of hard,

tempered steel, and are used to cut threads in metal,

fiber, or plastic. Four types of threads may be cut with

standard taps and dies. These are national coarse,

national fine, national extra fine, and national pipe. The

following paragraphs describe the types and uses of

taps, dies, and accessories.

4-38