TM 1-1500-204-23-9

(a)

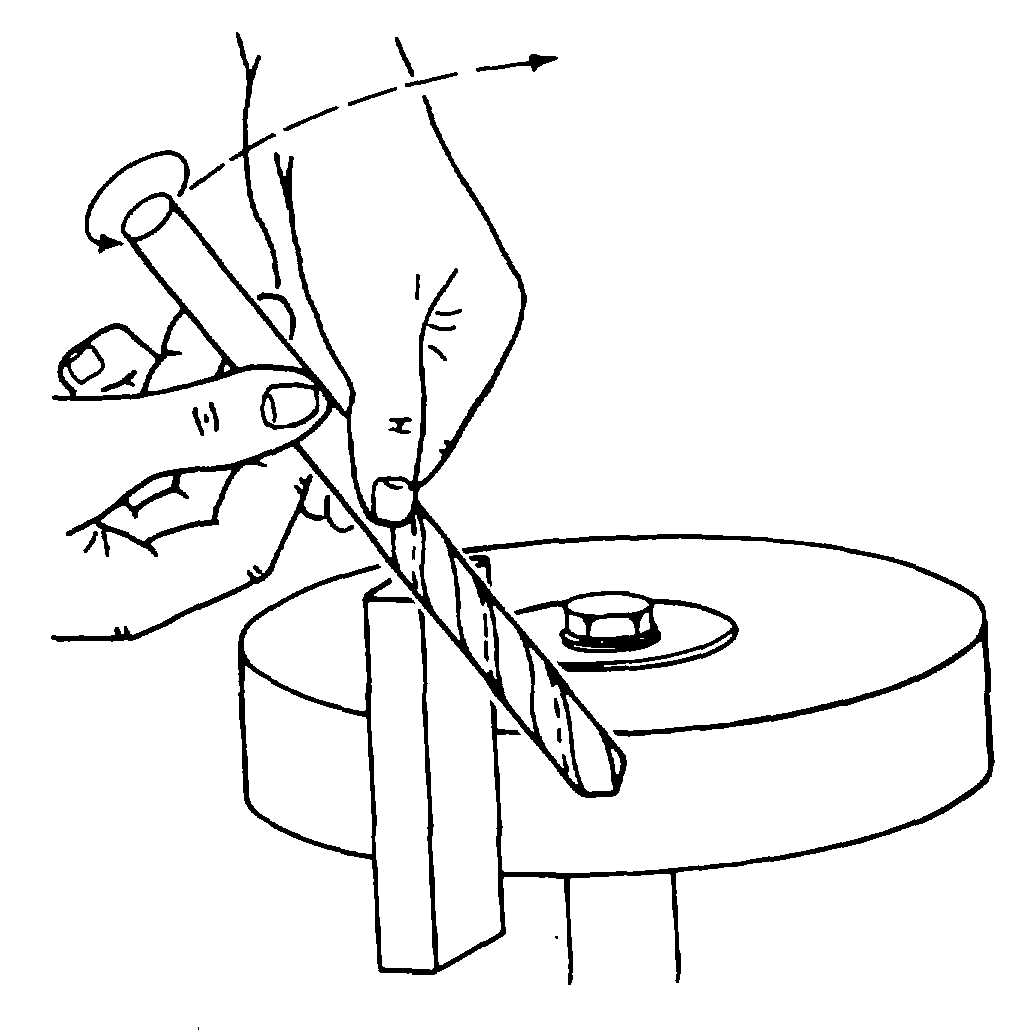

Adjust the grinding wheel rest to a

convenient height for resting the back of the hand while

grinding.

(b)

Hold the drill between the thumb and the

index finger and grasp the body of the drill near the

shank with the other hand.

WARNING

Eye protection will be worn when

grinding drills. Failure to comply may

result in serious injury to personnel.

(c)

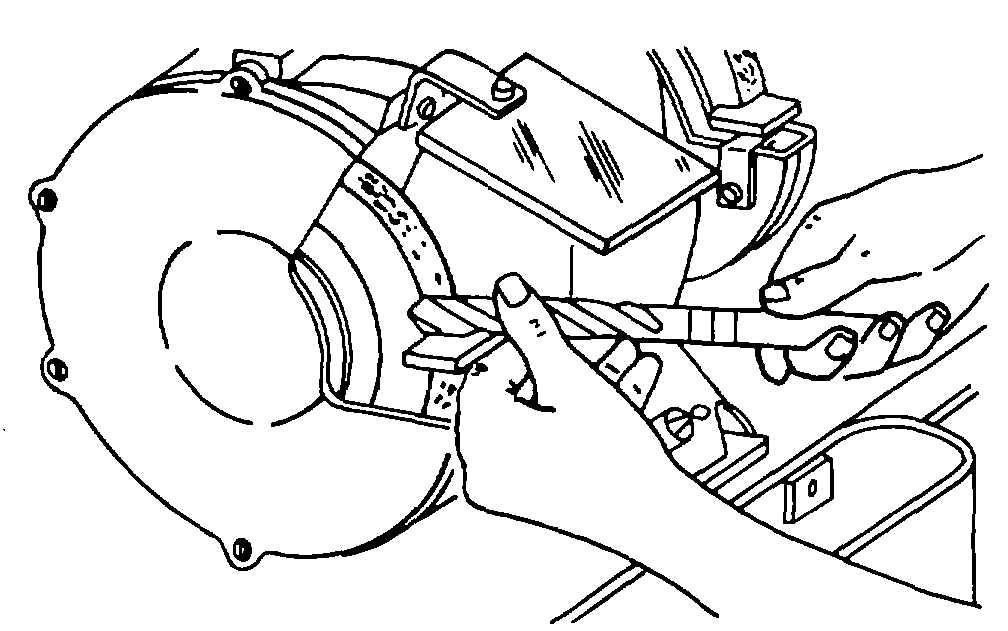

As shown in figure 4-87, place hand on

the wheel rest with the centerline of the drill forming the

desired angle with the cutting face of the wheel. Slightly

lower the shank end of the drill.

Figure 4-87. Hand Grinding of Cutting Edge

(d)

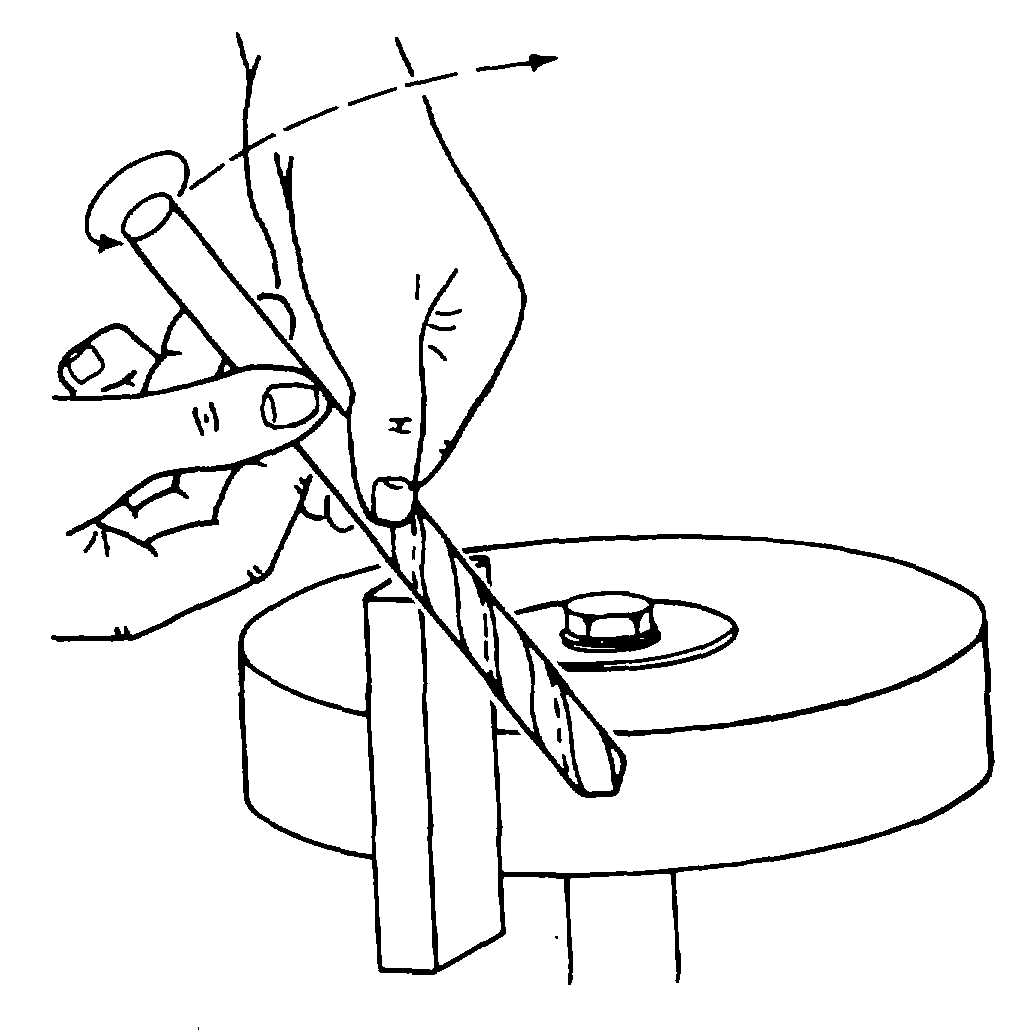

Slowly place the heel of the drill against

the grinding wheel, as shown in figure 4-88. Gradually

raise the shank end of the drill and rotate it in a

counterclockwise direction while the grinding wheel

approaches the cutting edge.

(e)

Cool the drill in water frequently while

grinding to preserve the temper.

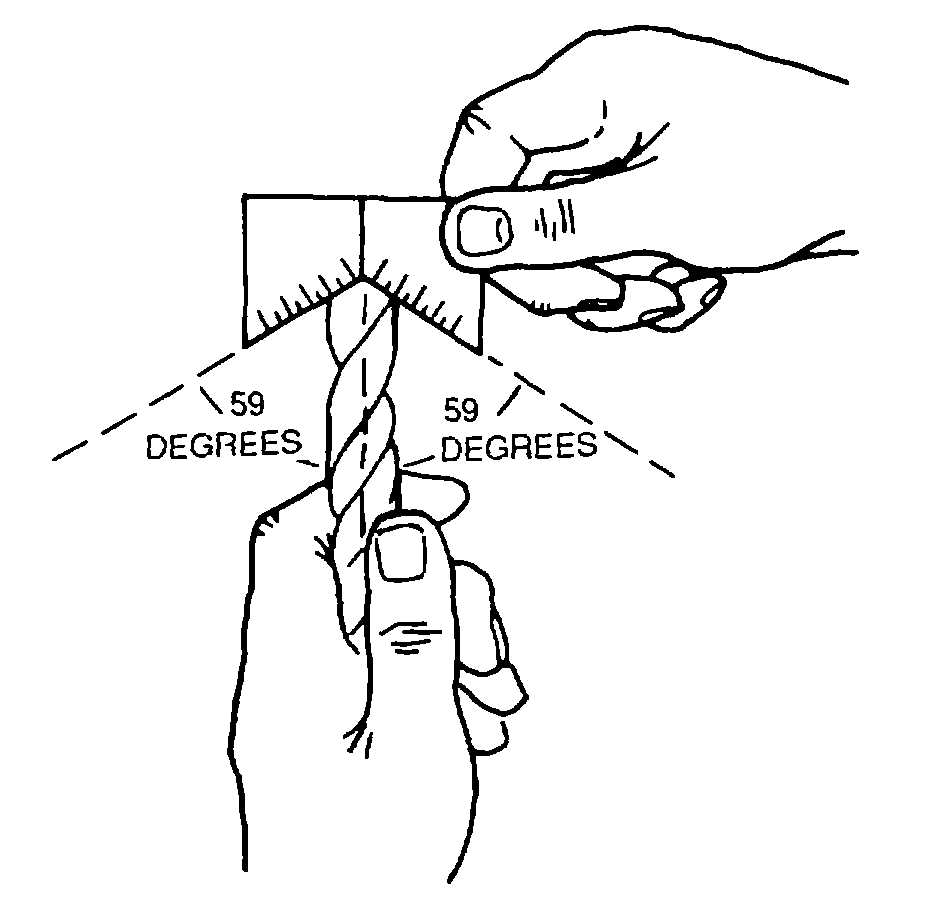

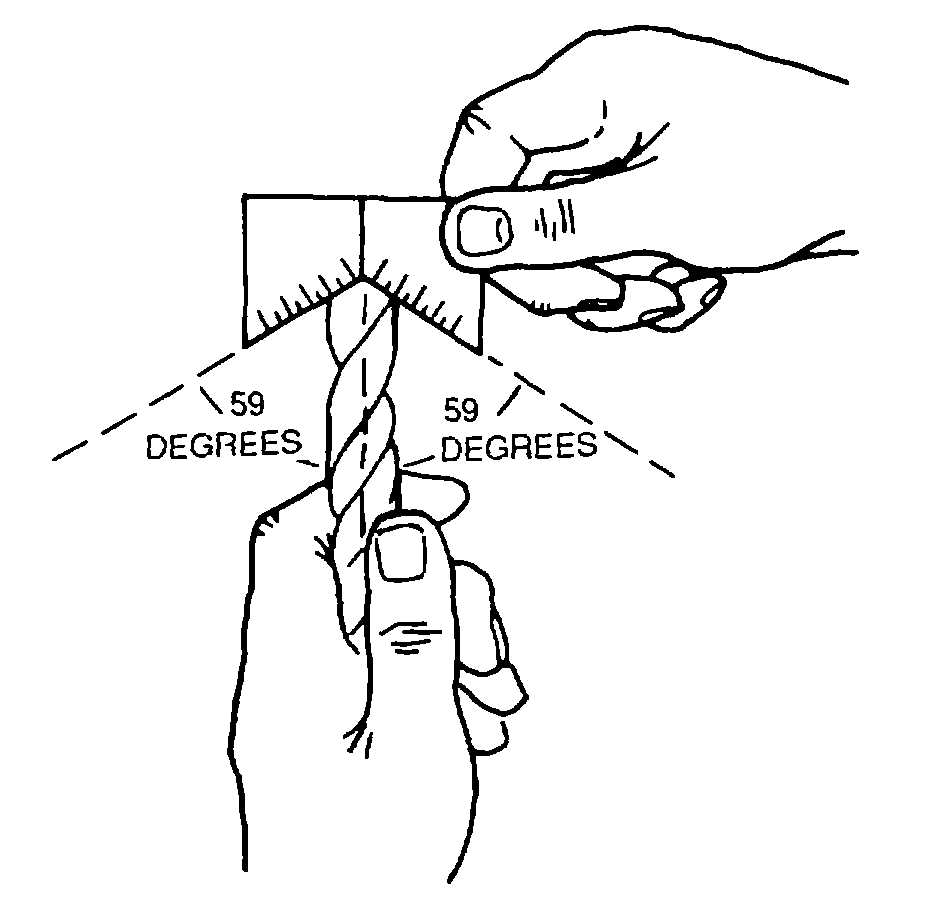

(3)

Testing angles. Test the results of

grinding with a drill grinding gauge to determine that the

cutting edges are the same length and the angles are

correct. This is shown in figure 4-89. To determine heel

angle, proceed as follows:

(a)

Cut a piece of paper 8-1/2 inches long

and 2 inches wide.

Figure 4-88. Hand Grinding of Heel to

Cutting Edge

Figure 4-89. Using Drill Grinding Gauge

(b)

Place a mark 1-1/4 inches from the top

and wrap the paper around the drill.

(c)

As shown in figure 4-90, the edge of the

paper should coincide with the mark on the paper if the

heel angle is correct.

4-33