TM 1-1500-204-23-9

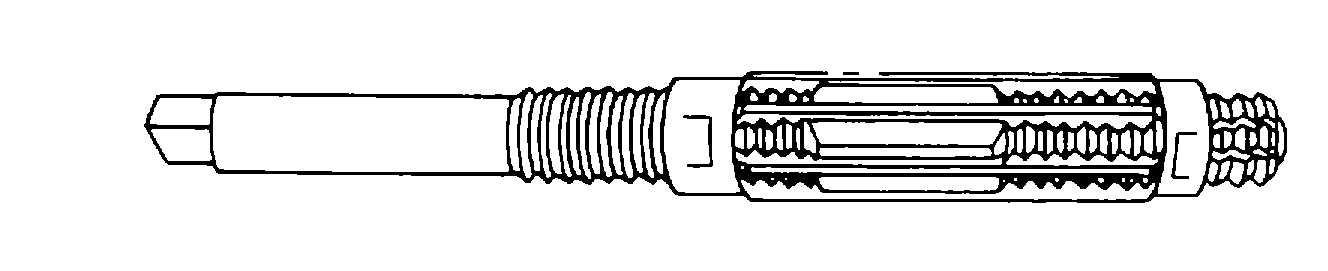

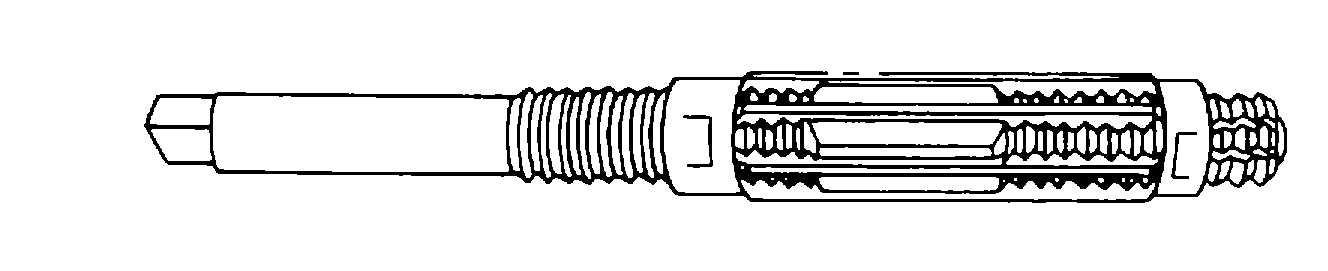

Figure 4-92. Adjustable Reamer

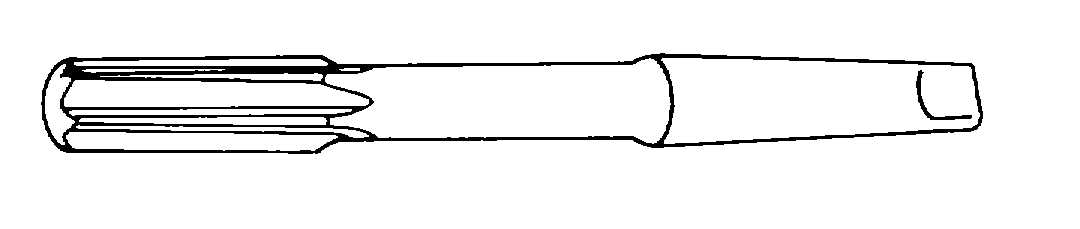

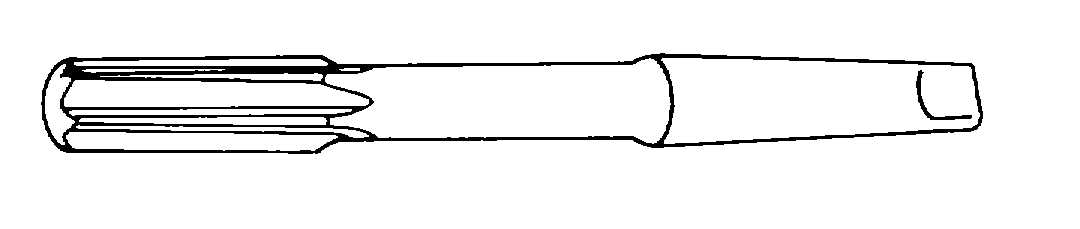

Figure 4-93. Jobber's (Machine) Reamer

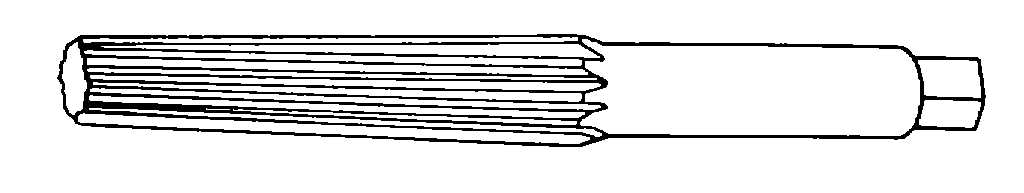

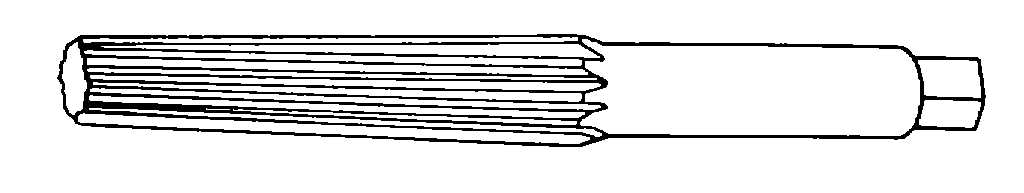

Figure 4-94. Brown and Sharpe Tapered Reamer

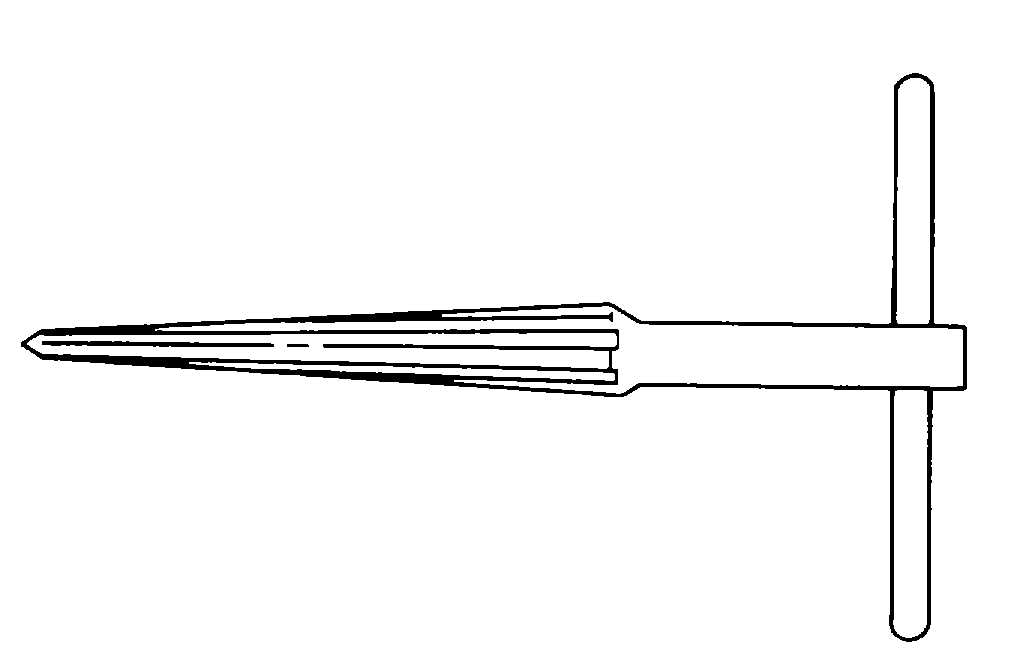

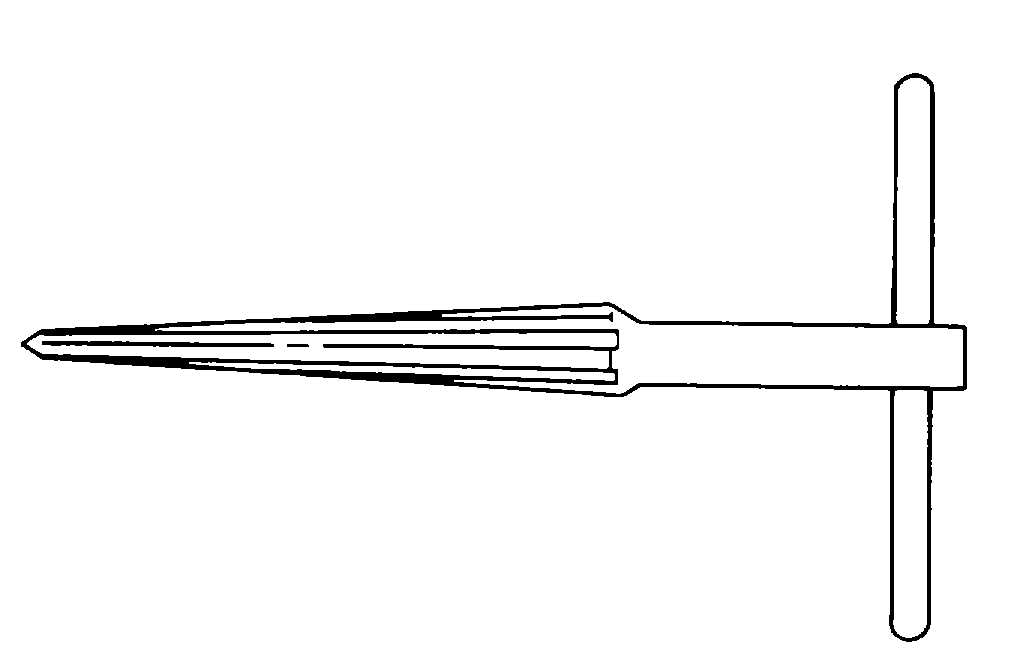

Figure 4-95. Repairman's Hand Reamer

NOTE

*

A reamer should enter a hole at

right angles to the work surfaces

to

permit

all

teeth

to

simultaneously engage. On a

curving surface, the rotating axis

of the reamer is presumed to be

at right angles to a plane tangent

at the point of entrance.

*

Where possible, provisions should

be made for the reamer to pass

through the workpiece. Line

reaming

is

required

for

concentricity and alignment of

holes.

*

Work

aids,

which

incorporate

bushings to guide the reamers,

are needed to produce holes that

are in parallel alignment at exact

distances from location points.

For long holes, it is preferable to

guide the reamers at both ends.

Work aids are locally fabricated.

*

Reamers are operated at slower

speeds and higher feed rates than

drills

of

the

corresponding

diameter. Reamer feed rates will

depend upon the type of metal

and the size or strength of the

reamer.

(1)

Secure the work in a vise so that the hole

to be reamed is perpendicular to the top of the vise

jaws.

(2)

Install the reamer shank into a tap wrench

and tighten the handle to clamp the reamer in place.

CAUTION

Turn the reamer in the cutting direction

(direction of the cutting edges) only. Do not

turn reamer backwards at any time. To do so

will result in rapid wear and dulling of the

cutting edges.

4-36