NAVAIR 01-1A-505-3

TO 1-1A-14-3

TM 1-1500-323-24-3

003 02

1 September 2011

Page 34

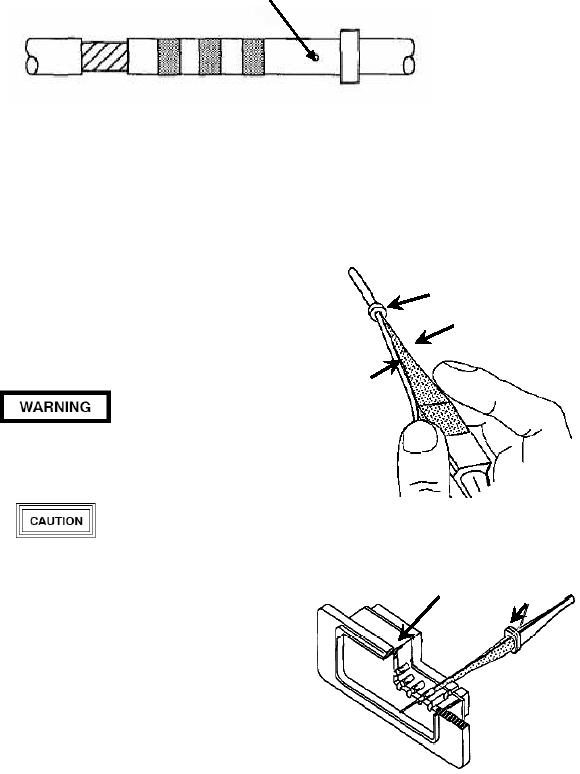

Contact Inspection Hole

Figure 16. Insulation Gap

34. CONTACT INSERTION. Insert wired or unwired

g. With firm even pressure, press tool against

contacts in accordance with following procedure:

contact shoulder and seat contact into cavity (Figure 18).

A slight click may be heard as retention tines snap into

a. Remove sealing plug and/or contact from contact

place behind contact shoulder.

cavity (Paragraph 38).

b. Ensure wire or cable on contact is routed through

Contact Shoulder

connector backshell.

c. Select correct insertion tool (Table 2).

Insertion Tool

d. Insert wire into insertion tool (Figure 17).

Wire

Metal tool tips are sharp and can cause injury to

personnel and/or damage to connectors.

Figure 17. Inserting Contact into Insertion Tool

Present metal tooling in some instances has

Retaining Clip Insertion Tool

damaged the wire sealing grommet at the end of

the connectors. Plastic tools are preferred.

Caution should be exercised in the use of tooling.

Inspect tips of metal tools for distortion of probe

before use as connector damage can occur.

e. Insert tip of contact into cavity. Start contact

insertion near connector center cavities and work

outward.

f. Axially align contact with contact cavity.

Figure 18. Contact Insertion