TM 1-1510-262-10

SECTION XV. SERVICING, PARKING, AND MOORING

2-90. GENERAL.

The following paragraphs include the procedures necessary to service the aircraft except lubrication. The lubrication

requirements of the aircraft are covered in the aircraft maintenance manual. Table 2-9, Table 2-10, Table 2-11, and

Table 2-12 are used for identiication of fuel, oil, etc. used to service the aircraft. The servicing instructions provide

procedures and precautions necessary to service the aircraft. Figure 2-44 shows the servicing location points.

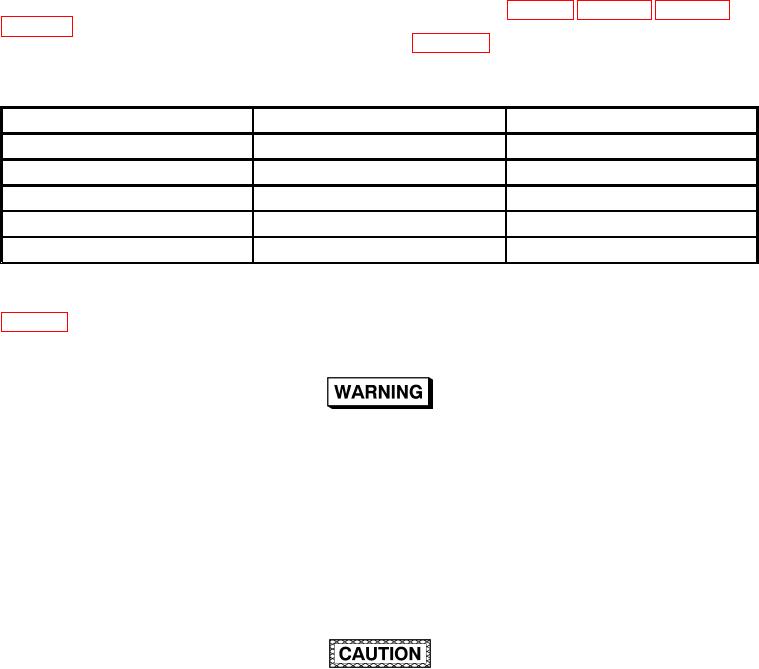

Table 2-9.

Approved Military Fuels, Oil, Fluids and Unit Capacities

SYSTEM

SPECIFICATION

CAPACITY

Fuel

MIL-T-83133 (JP-8)

540 U.S. Gals. Useable

MIL-L-23699

Engine Oil

10 U.S. Quarts per engine

MIL-H-5606

Hydraulic Brake System

1 U.S. Pint

MIL-0-27210

Oxygen System

140 Cubic Feet

Toilet Chemical

Monogram DG-19

3 Ounces

2-91. FUEL HANDLING PRECAUTIONS.

Table 2-2, Fuel Quantity Data, lists the quantity and capacity of fuel tanks in the aircraft. Service the fuel tanks after

each light to keep moisture out of the tanks and to keep the bladder type cells from drying out. Observe the following

precautions:

During warm weather, open fuel caps slowly to prevent being sprayed with fuel.

Prior to removing the fuel tank iller cap, the hose nozzle static ground wire shall be attached to

the grounding sockets located adjacent to the iller opening.

Care should be taken to prevent cuts or abrasions while inspecting the exhaust or turbine area

of engines that have been operated on aviation gasoline. The exhaust deposits can cause lead

poisoning.

When conditions permit, the aircraft shall be positioned so that the wind will carry the fuel vapors

away from all possible sources of ignition. The fueling vehicle shall be positioned to maintain a

minimum distance of 10 feet from any part of the aircraft, while maintaining a minimum distance

of 20 feet between the fueling vehicle and the fuel iller point.

Proper procedures for handling aircraft fuels cannot be over stressed. Clean, fresh fuel shall be used

and the entrance of water into the fuel storage or aircraft fuel system must be kept to a minimum.

a. Shut off unnecessary electrical equipment in the aircraft, including radar and radar equipment. The master

switch may be left on, to monitor fuel quantity gauges, but shall not be moved during the fueling operation. Do not

allow operation of any electrical tools, such as drills or buffers, in or near the aircraft during fueling.

b. Keep fuel servicing nozzles free of snow, water, and mud at all times.

c. Carefully remove snow, water, and ice from the aircraft fuel iller cap area before removing the iller cap. Re-

move only one aircraft tank iller cap at any one time, and replace each one immediately after the servicing operation

is completed.

d. Wipe all frost from fuel iller necks before servicing the aircraft.