TM 10-4930-351-14

0006 00

Table 1. Operator's Preventive Maintenance Checks and Services for AAFARS (Continued)

Item Interval

Location

Procedure

Not Fully Mission

No.

Capable If:

Item to Check/

Service

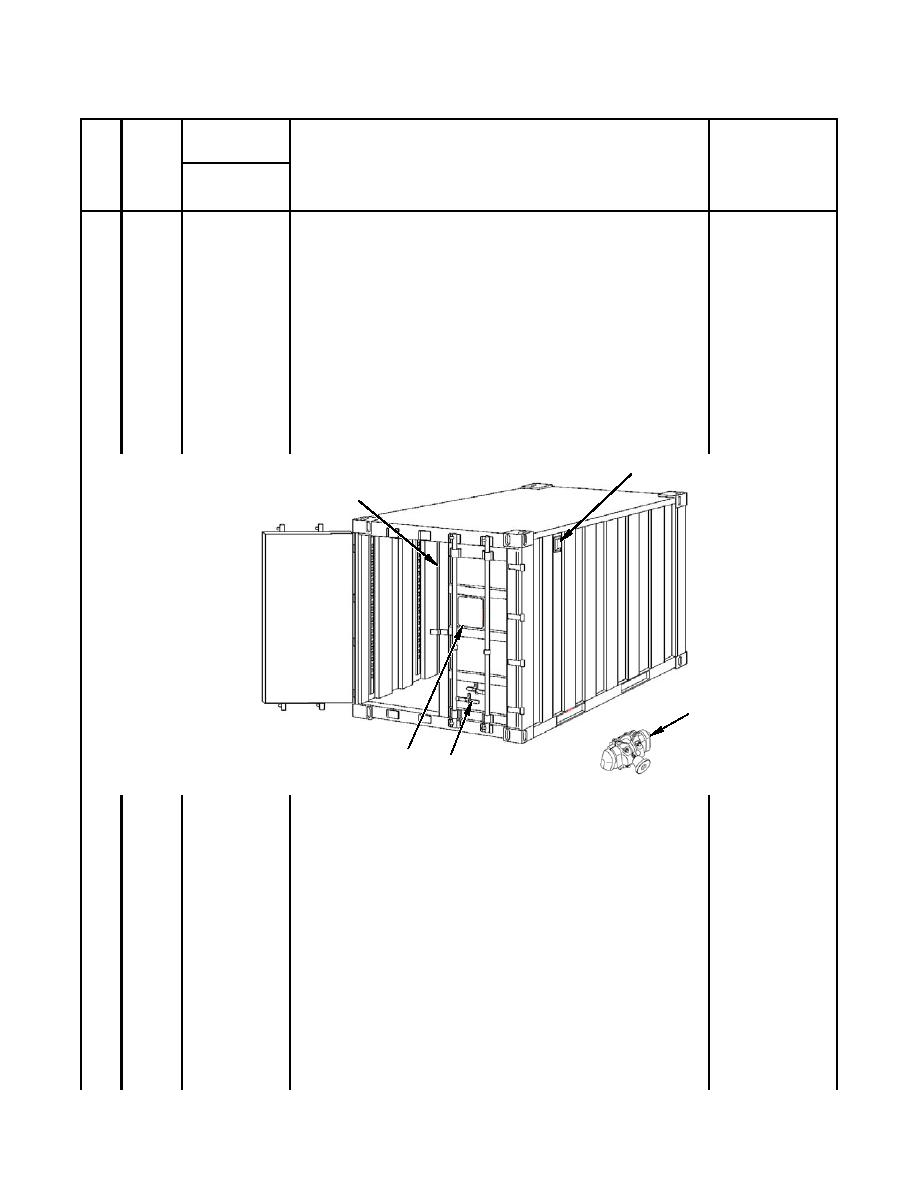

38

Before TRICON

Inspect document holder (2) for any large dents that may prevent

Document holder

Container

the holder from being completely opened or closed.

cannot be

completely opened

or closed.

39

Before TRICON

Inspect door seals (3) for tears.

Door seals are torn.

Container

40

Before TRICON

Inspect for broken vents (4).

Vents are broken.

Container

41

Before TRICON

Check that connecting link assembly (5) handle can be pulled out

If handle is jammed

Container

and shifted 90 degrees.

or cannot be

shifted.

4

3

5

2

1

42

During System

Periodically check for leaks, especially at unisex couplings,

Any Class I, Class

pressure control, and the engine module.

II or Class III fuel

leak is found.

43

During System

Check hoses for soft spots, often noticed as localized swelling.

Any hose exhibits

soft spots,

especially one that

is spreading.

44

During Liquid Fuel

Monitor differential pressure gauge for reading approaching or

Differential

Filter-Separator exceeding 15 psid. Notify unit maintenance that coalescer element

pressure gauge

replacement is required if reading exceeds 15 psid.

reading exceeds 15

psid.

45

During Liquid Fuel

Monitor water level indicator. Drain sump at first opportunity if

Water level in sump

Filter-Separator indicator ball rises near top of sight gauge.

rises to top of sight

gauge.

0006 00-10