TM 10-4930-351-14

0006 00

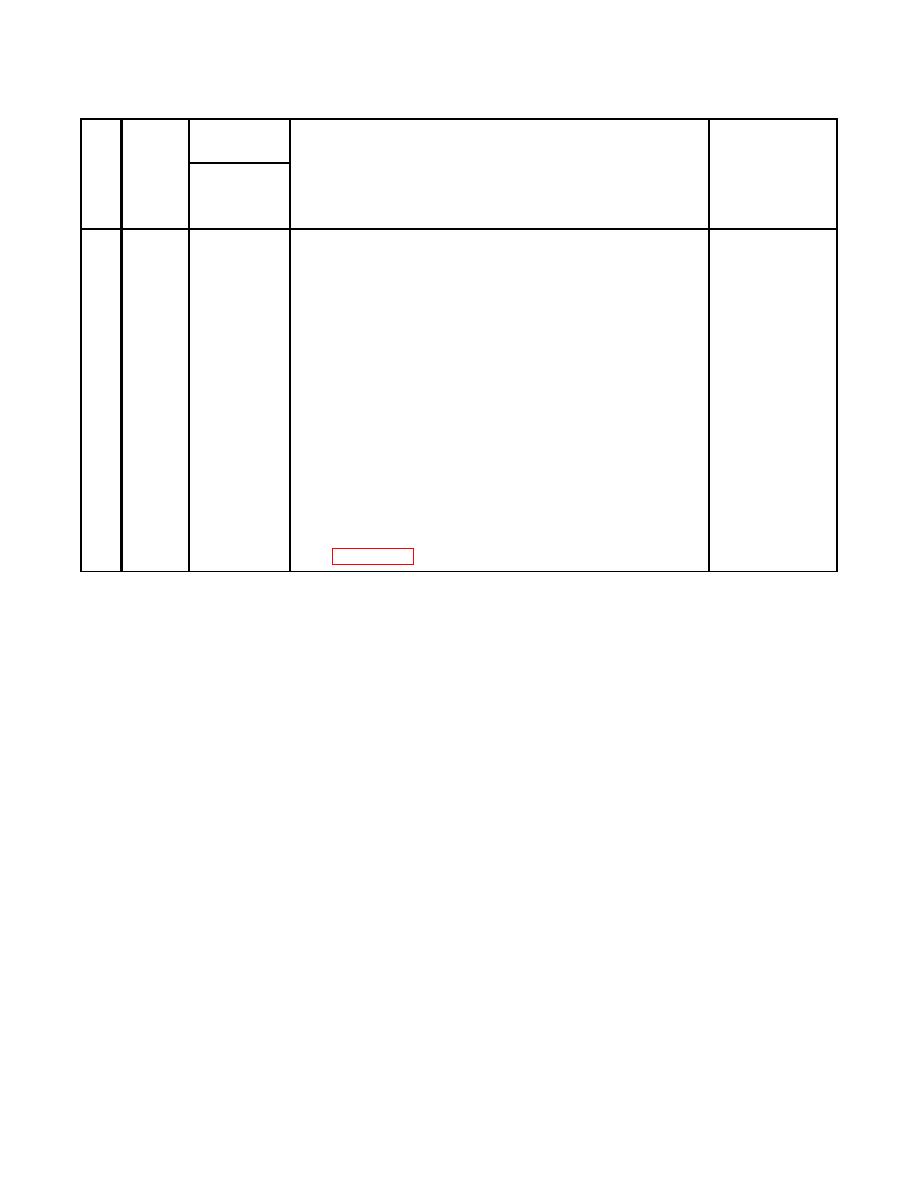

Table 1. Operator's Preventive Maintenance Checks and Services for AAFARS (Continued)

Item Interval

Location

Procedure

Not Fully Mission

No.

Capable If:

Item to

Check/

Service

63

After

D1-Nozzle

Attempt to open the nozzle with the lever (9).

Nozzle opens.

64

After

Pressure

Check exterior parts for cracks and leaks. Check female coupling

Any damage that

Control

half for missing or damaged gasket. Check for missing or damaged would cause leaks.

dust plug. Check dust cap for missing or damaged gasket.

65

After

Fuel Drums

Check the adapter assembly for cracks, leaks, and damaged threads. Any damage that

would interfere

with installation or

cause leaks.

Drum has puncture

66

After

Fuel Drums

Check the fuel drum fabric for cuts, holes, deterioration, and leaks.

and or excessive

Check the metal parts for cracks, leaks, and loose capscrews. No

wear.

fabric cords should be showing through the rubber ream of the

drum body

67

Quarterly Pressure

Check exterior parts for cracks and leaks. Check for missing or

Any damage that

Control

damaged gaskets, dust plug and dust. Check pressure control for

would cause leaks

proper operation. Test pilot valve; correct shutoff pressure is 4.5 to

or shutoff pressure

5 psi. (WP 0083 00)

is not correct.

0006 00-13/14 blank