TM 10-4930-351-14

0006 00

Table 1. Operator's Preventive Maintenance Checks and Services for AAFARS (Continued)

Item Interval

Location

Procedure

Not Fully Mission

No.

Capable If:

Item to Check/

Service

55

After

D1-Nozzle

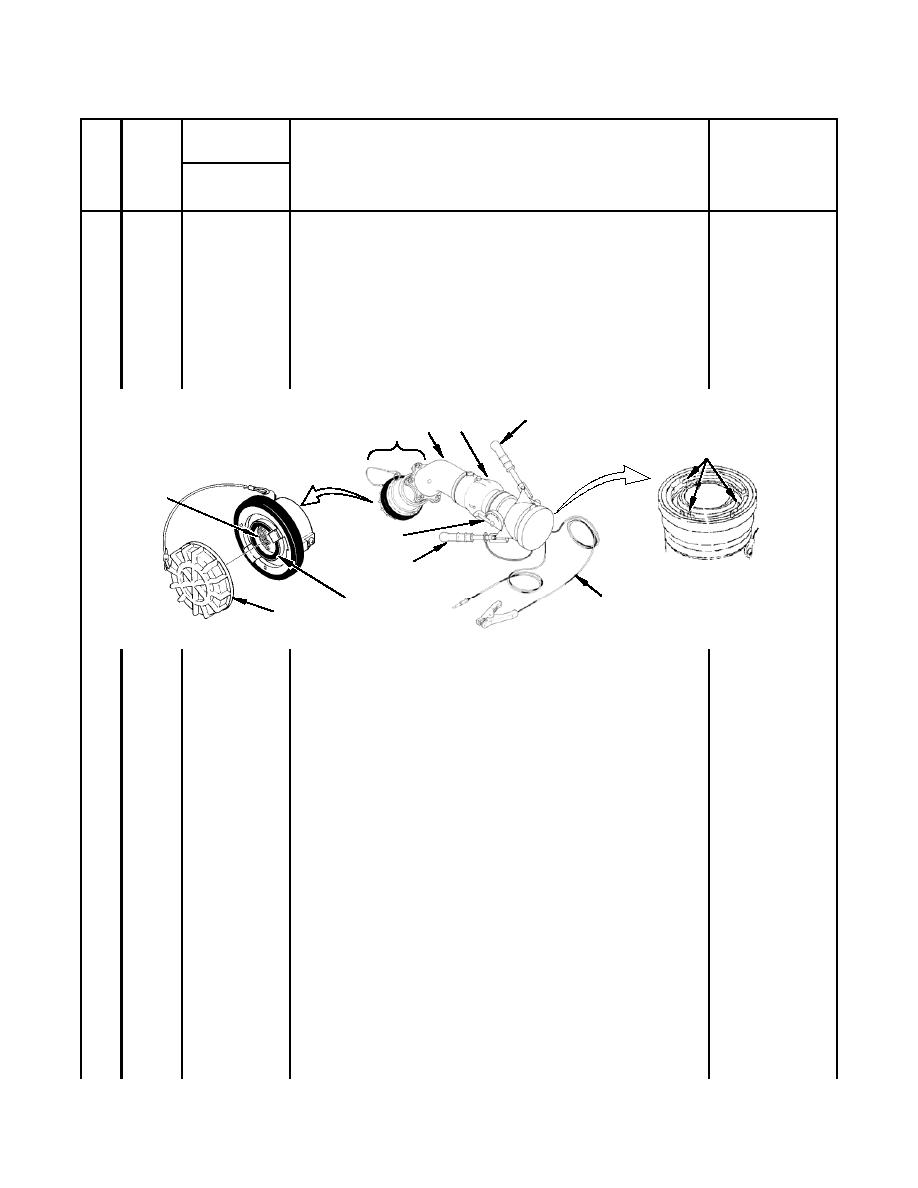

Check unisex disconnect assembly (1) body for any deformation,

Any damage would

cracks, or internal gouges.

interfere with

installation or cause

leaks.

56

After

D1-Nozzle

Check that face seal (2) is in place and not damaged.

Face seal is missing

or damaged.

57

After

D1-Nozzle

Check strainer (3) for obstructions or tears.

Strainer obstructed

or torn.

7

5

4

1

8

3

9

7

6

2

10

58

After

D1-Nozzle

Check inlet elbow (4) and regulator (5) for cracks.

Damaged enough to

cause leaking or

interfere with

operation.

59

After

D1-Nozzle

Check grounding cable assembly (6) and verify that grounding

Grounding cable,

cable, bonding plug and grounding clamp are in place and in good

bonding plug, and

condition.

grounding clamp

are broken or

missing.

60

After

D1-Nozzle

Check that handles (7) are in place and in good condition.

Handles are

missing or damaged

enough to prevent

operation.

61

After

D1-Nozzle

While disconnecting the nozzle, if the collar lock pins (8) are not

Pins do not spring

extended and engaged in all three cutouts in the collar, the operator back into collar

should squeeze the lever (9) and handle grip together while

cutouts.

observing the connecting end of the nozzle. This should cause the

collar lock pins (8) to spring into the cutouts in the collar. Failure of

above could also indicate mating adapter problem.

62

After

D1-Nozzle

Check that dust cover (10) is in place and in good condition.

Dust cover missing

or damaged.

0006 00-12