TM 1-1500-204-23-1

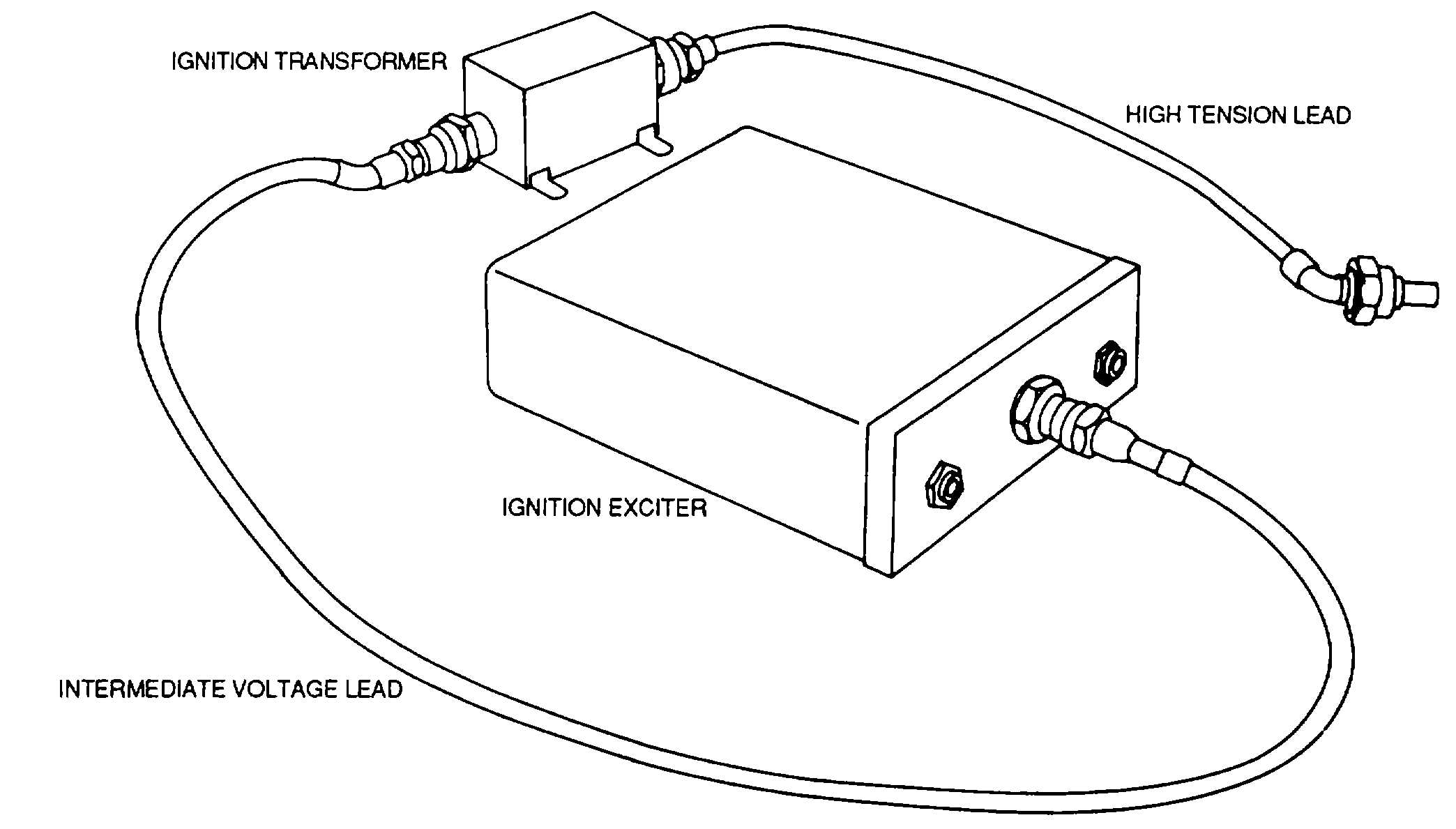

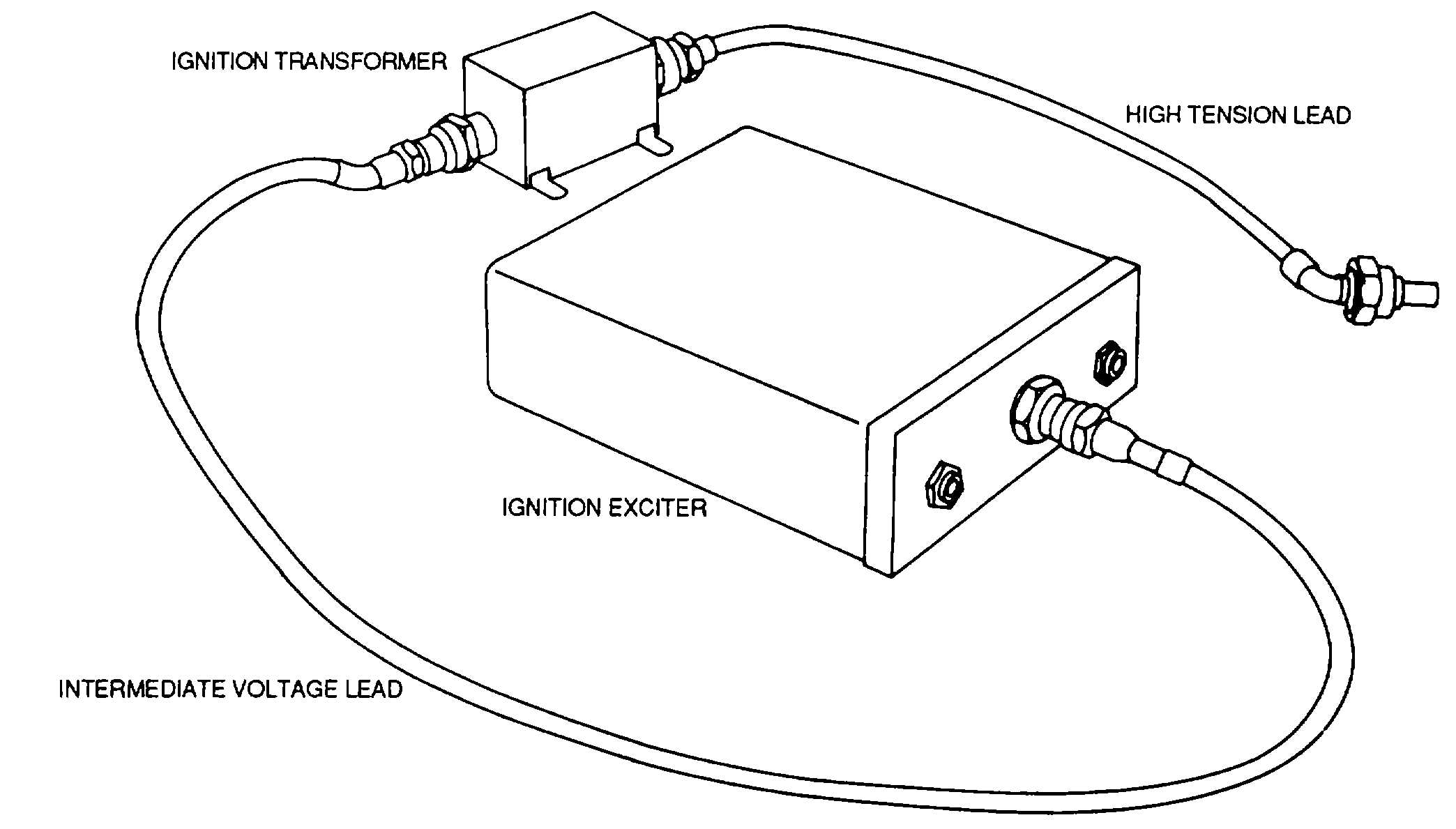

Figure 8-13. One Side of a Typical Ignition System

(1) Fuel controls. Regardless of the type, all fuel

controls accomplish essentially the same functions, but

some sense more engine variables than others. The

fuel control senses power lever position, engine rpm,

either compressor inlet pressure or temperature, and

burner pressure or compressor discharge pressure.

These variables affect the amount of thrust that an

engine will produce for a given fuel flow.

(2) Fuel nozzles. The fuel nozzles inject fuel into

the combustion area In a highly atomized, precisely

patterned spray so that burning is completed evenly and

in the shortest possible time and in the smallest possible

space. Fuel nozzle types vary considerably between

engines, although for the most part fuel is sprayed into

the combustion area under pressure through small

orifice in the nozzles The two types of fuel nozzles

generally used are the simplex and the duplex

configurations.

(a) Simplex fuel nozzle. The simplex fuel nozzle

was the first type nozzle used in turbine engines and

was replaced in most installations with the duplex

nozzle, which gave better atomization at starting and

idling speeds. The simplex nozzle, as shown in figure 8-

15, is still being used to a limited degree. Each of the

simplex nozzles consists of a nozzle tip, an insert, and a

strainer made up of fine-mesh screen and a support.

(b) Duplex fuel nozzle. The duplex fuel nozzle is

the nozzle most widely used in present-day gas turbine

engines The duplex nozzle usually requires a dual

manifold and a pressurizing valve or flow divider for

dividing primary and main fuel flow into a desirable

spray pattern for combustion over a wide range of

operating pressures. A nozzle typical of this type is

shown In figure 8-16.

(3) Fuel filters. A low-pressure filter Is installed

between the supply tanks and the engine fuel system to

protect the engine-driven fuel pump and various control

devices. An additional high-pressure fuel filter is

installed between the fuel pump and the fuel control to

protect the fuel control from contaminants. The three

most common types of filters in use are the micron filter,

the wafer screen filter, and the plain screen mesh filter.

The individual use of each of these filters is dictated by

the filtering treatment required at a particular location.

8-6. Turbine Engine Inspection and Maintenance.

Turbine engines shall be Inspected and maintained in

accordance with the applicable maintenance manual.

General procedures for various components and

systems are explained in the following paragraphs.

8-11