TM 1-1500-204-23-1

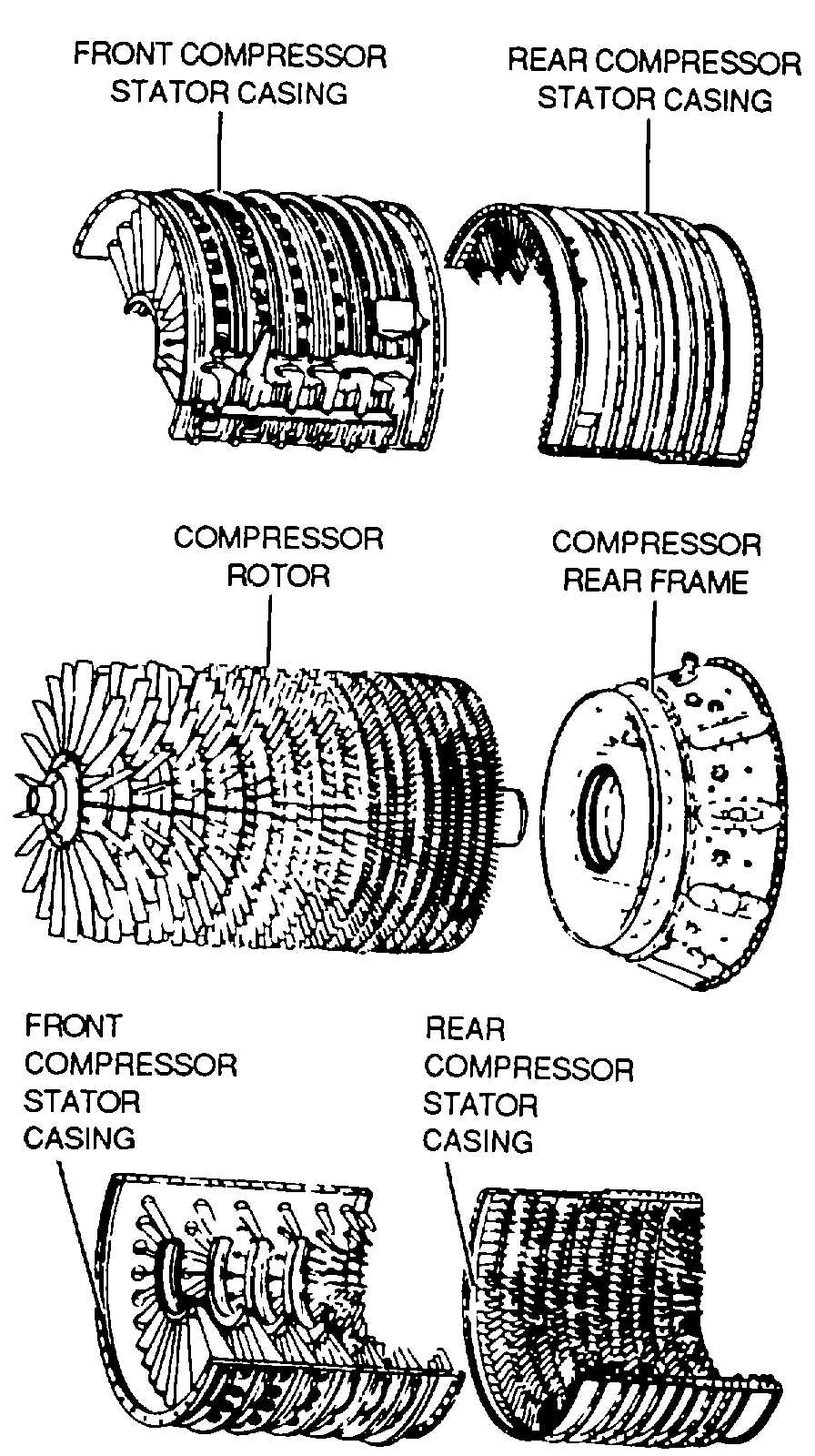

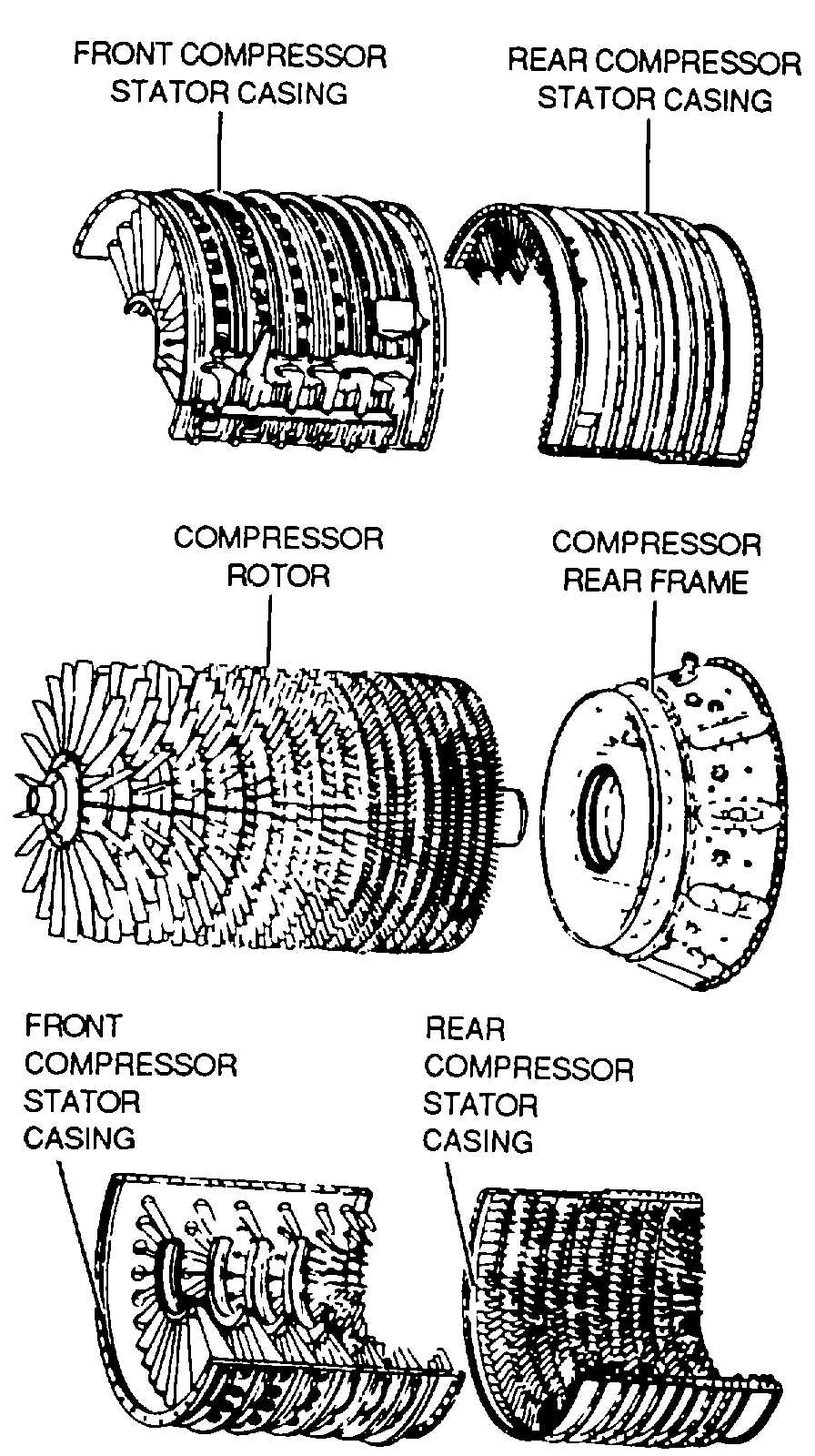

Figure 8-7. Rotor and Stator Components of an

Axial-Flow Compressor

(b) Speed-set governor. The speed-set governor,

as shown in figure 8-12, controls the position of the

governor servo. It is a centrifugal, permanent-droop

type governor driven by the engine high-speed rotor (N2)

through a gear train. As engine speed increases, the

fly-weights tend to move outward, lifting the speed set

pilot valve. Conversely, when engine speed decreases,

the fly-weights move inward and the pilot valve is

lowered. The power lever in the cockpit positions the

speed-setting cam in the fuel control unit to manipulate

a system of levers and thus control the compression of

the speeder spring. The speeder spring exerts force on

the speed-set pilot valve. The condition of on-speed

indicates the speeder spring force and the flyweight

force are equal.

(2) Fuel controls. Fuel controls can be divided into

two basic groups hydromechanical and electronic. The

fuel control senses power lever position, engine rpm,

either compressor inlet pressure or temperature, and

burner pressure of compressor discharge pressure.

These variables affect the amount of thrust that an

engine will produce for a given fuel flow.

(a)

Hydromechanical

fuel

controls.

Hydromechanical

fuel

controls

are

extremely

complicated and are composed of speed governors,

servo systems, sleeve and pilot valves, feedback or

follow up devices, and metering systems.

(b) Electron/c fuel controls Electronic fuel

controls contain the same Items as the hydromechanical

fuel control as well as amplifiers, thermocouples, relays,

electrical servo systems, switches, and solenoids.

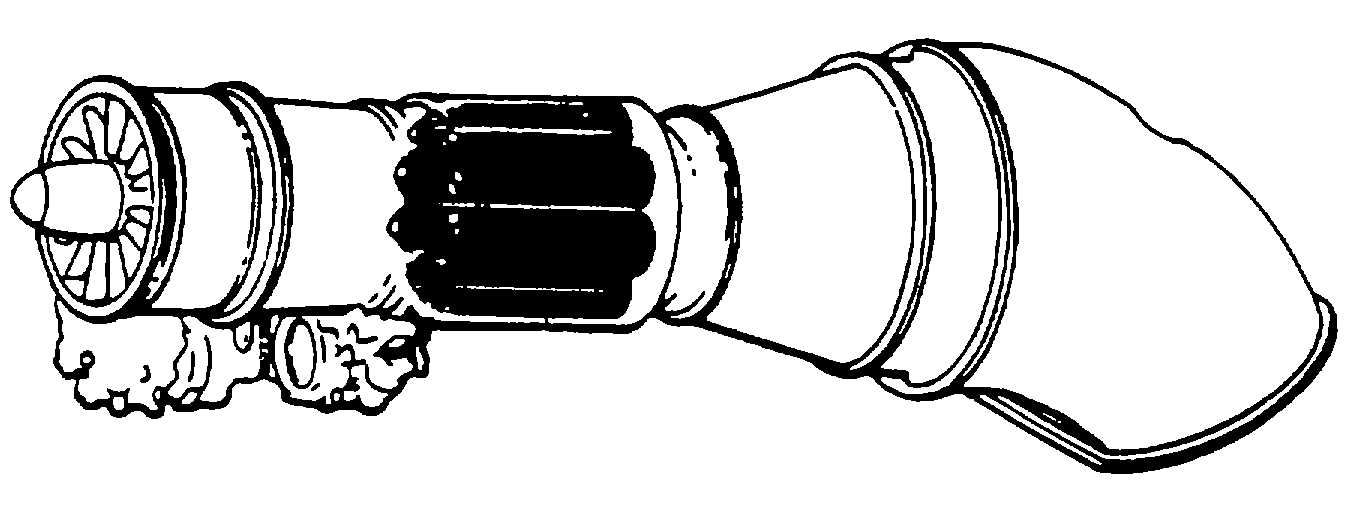

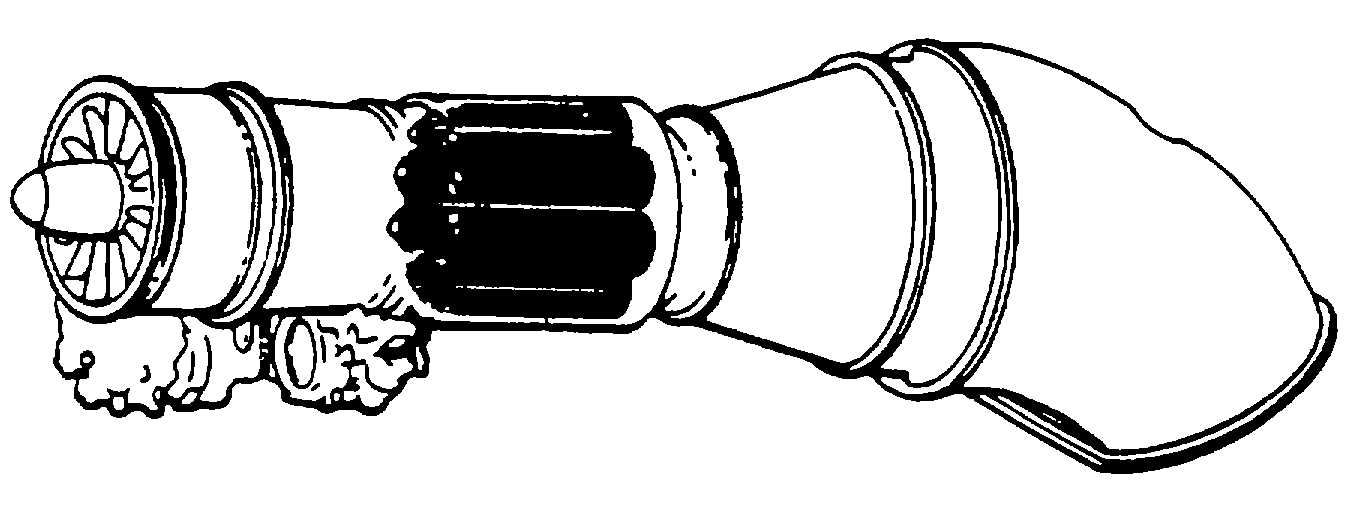

Figure 8-8. Can-Type Combustion Chamber Arrangement

8-7