TM 1-1500-204-23-1

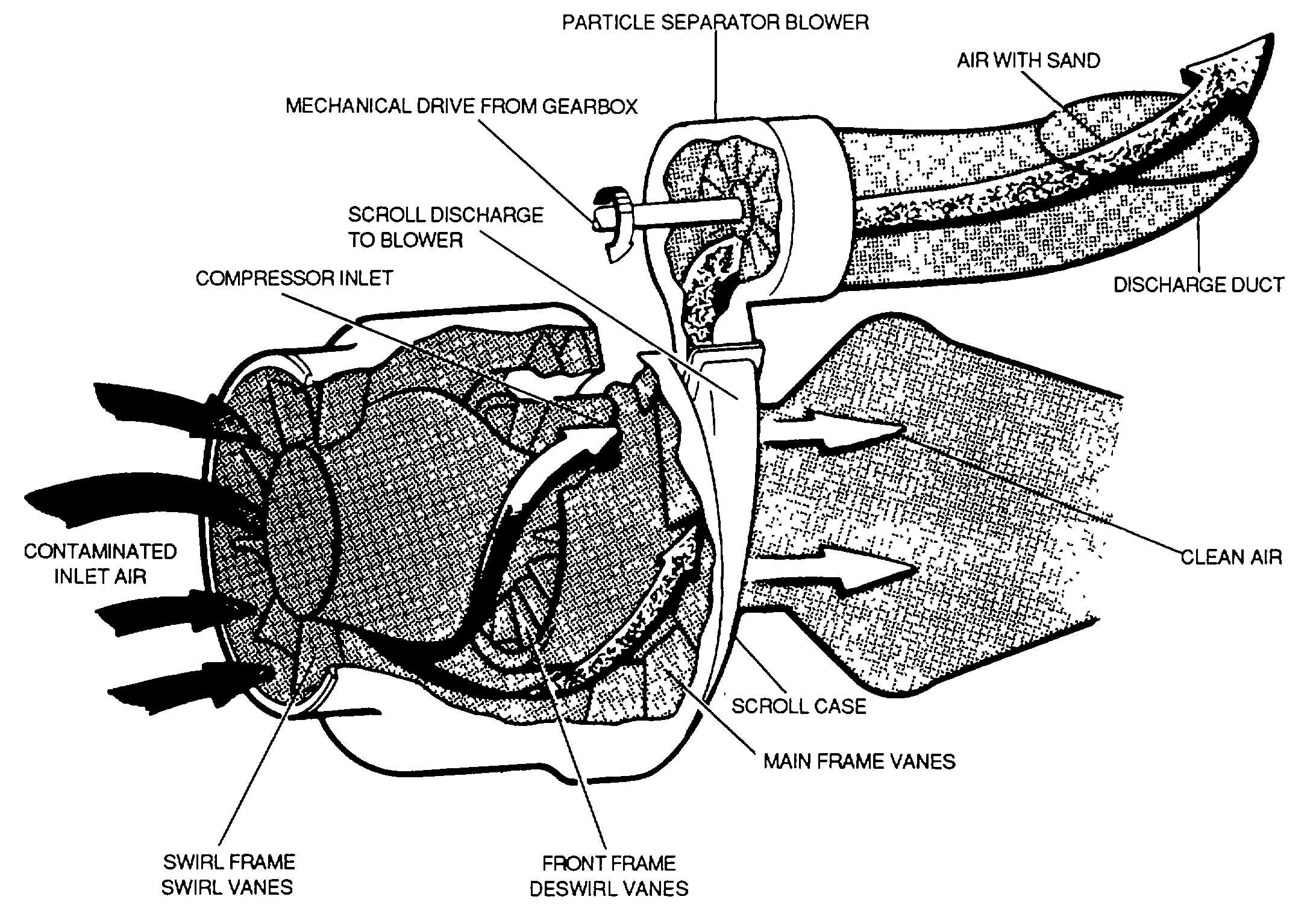

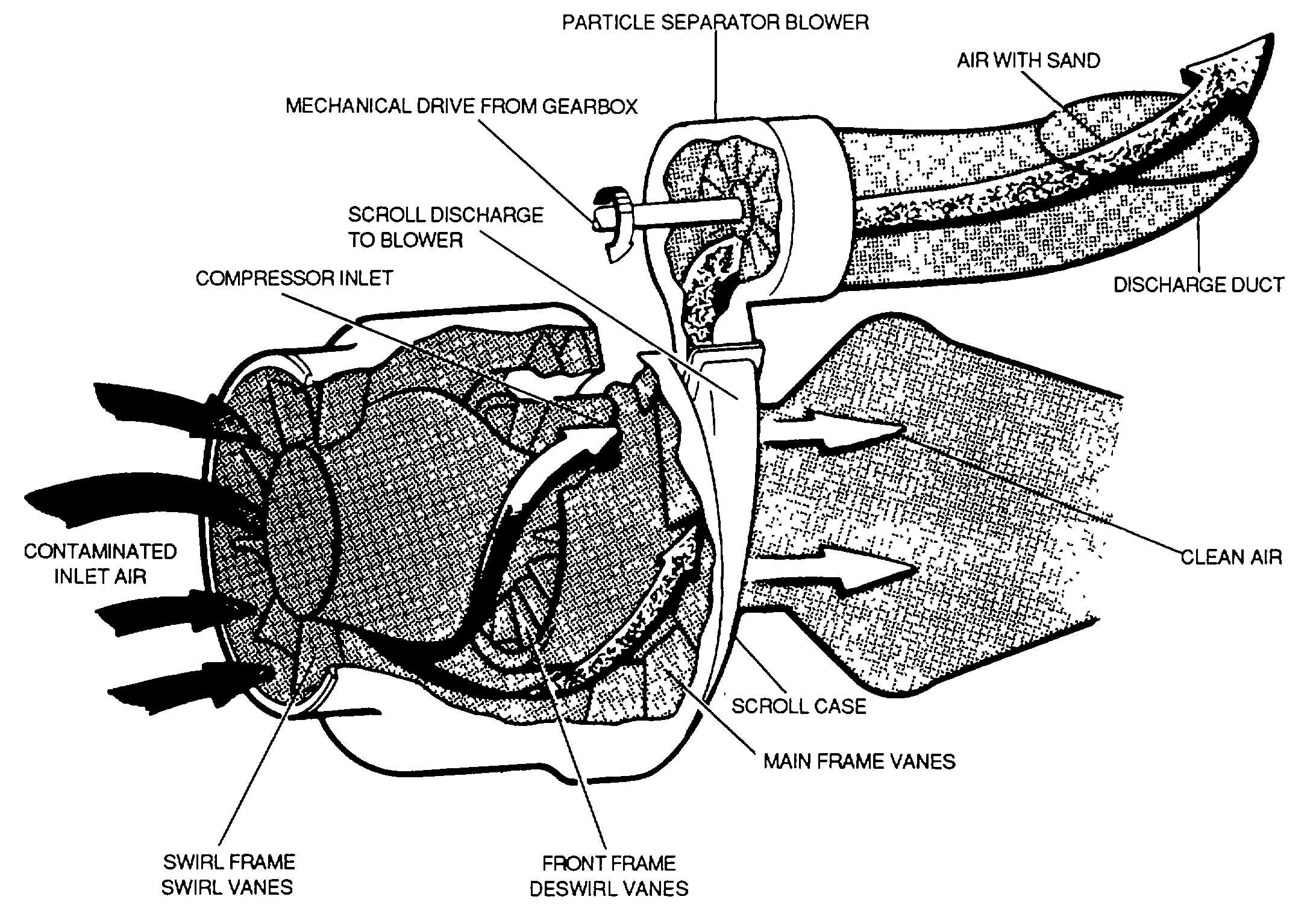

Figure 8-5. Particle Separator

d. Diffuser Section. The diffuser increases the

compressor discharge area and reduces the speed of

the centrifugal impeller airflow, causing the air pressure

to increase. This pressurized air is directed to the

combustor through the diffuser case The diffuser case

mounts on the rear flange of the compressor stator it

directs compressor discharge air to the combustion

chamber.

e. Combustion Section. The combustion section

houses the combustion process, which raises the

temperature of the air passing through the engine. This

process releases energy contained in the air-fuel

mixture. The major part of this energy is required at the

turbine to drive the compressor. The remaining energy

creates the reaction or propulsion and passes out the

rear of the engine in the form of a high-velocity jet. The

location of the combustion section is directly between

the compressor and the turbine sections. The

combustion chamber is always arrange coaxially with

the compressor and turbine regardless of type, since the

chambers must be In a through-flow position to function

efficiently.

Can-Type. The can-type combustion is typical of

the type used on both centrifugal and axial-flow engines

Figure 8-8 illustrates the arrangement for can-type

combustion.

The

engine

combustion

cans

are

numbered in a clockwise direction facing the rear of the

engine with the No. 1 can at the top. The can-type

combustion consist of an outer case or housing, which is

perforated stainless steel (highly heat resistant) (See

Figure 8-9).

f. Turbine Section. The turbine transforms a portion

of the kinetic (velocity) energy of the exhaust gases into

mechanical energy to drive the compressor and

accessories. This is the sole purpose of the turbine and

this function absorbs approximately 60 to 80 percent of

the total pressure energy from the exhaust gases. The

turbine assembly consists of two basic elements, the

stator and the rotor, as does the compressor unit.

These two elements are shown in figure 8-10.

8-5