TM 1-1500-204-23-1

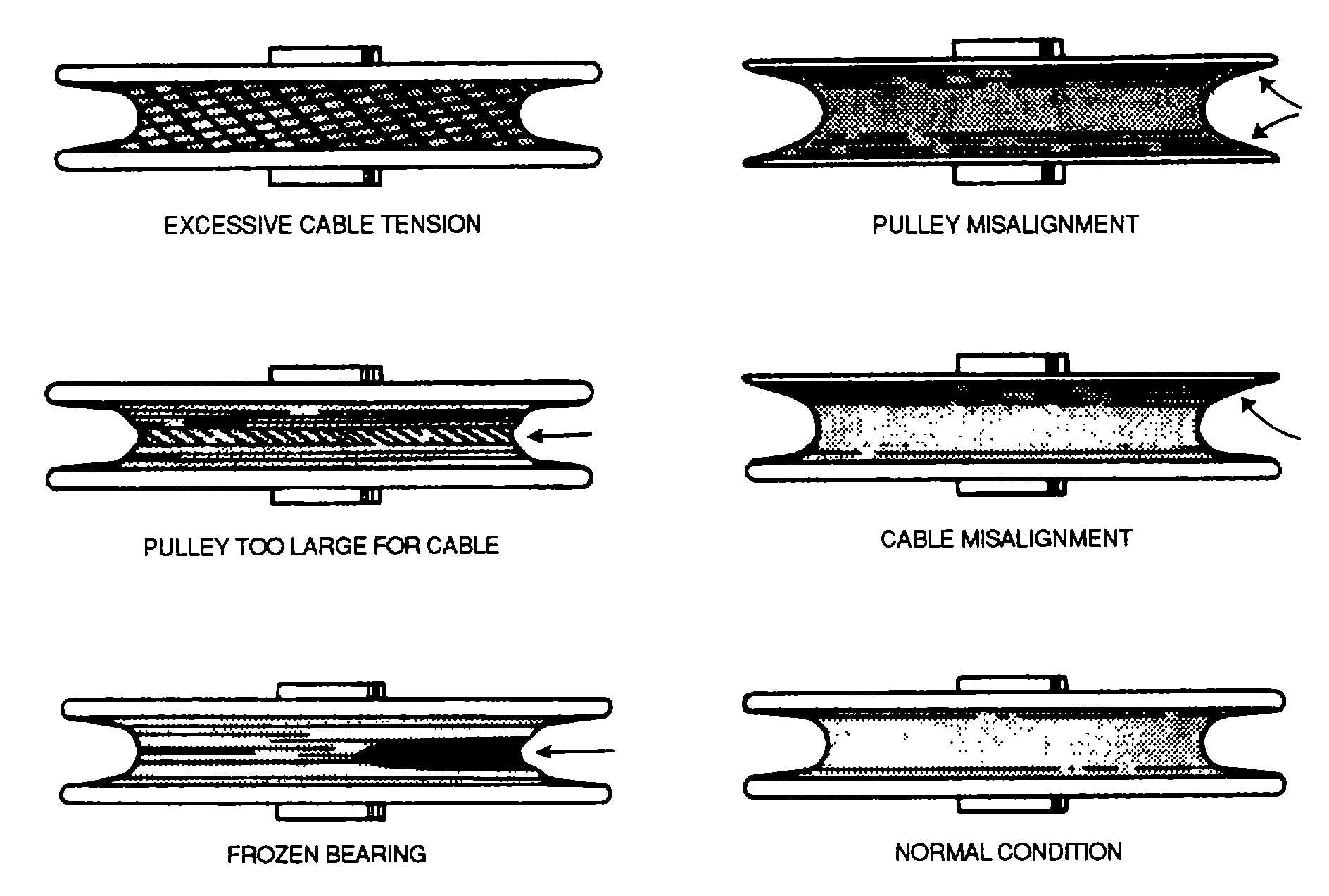

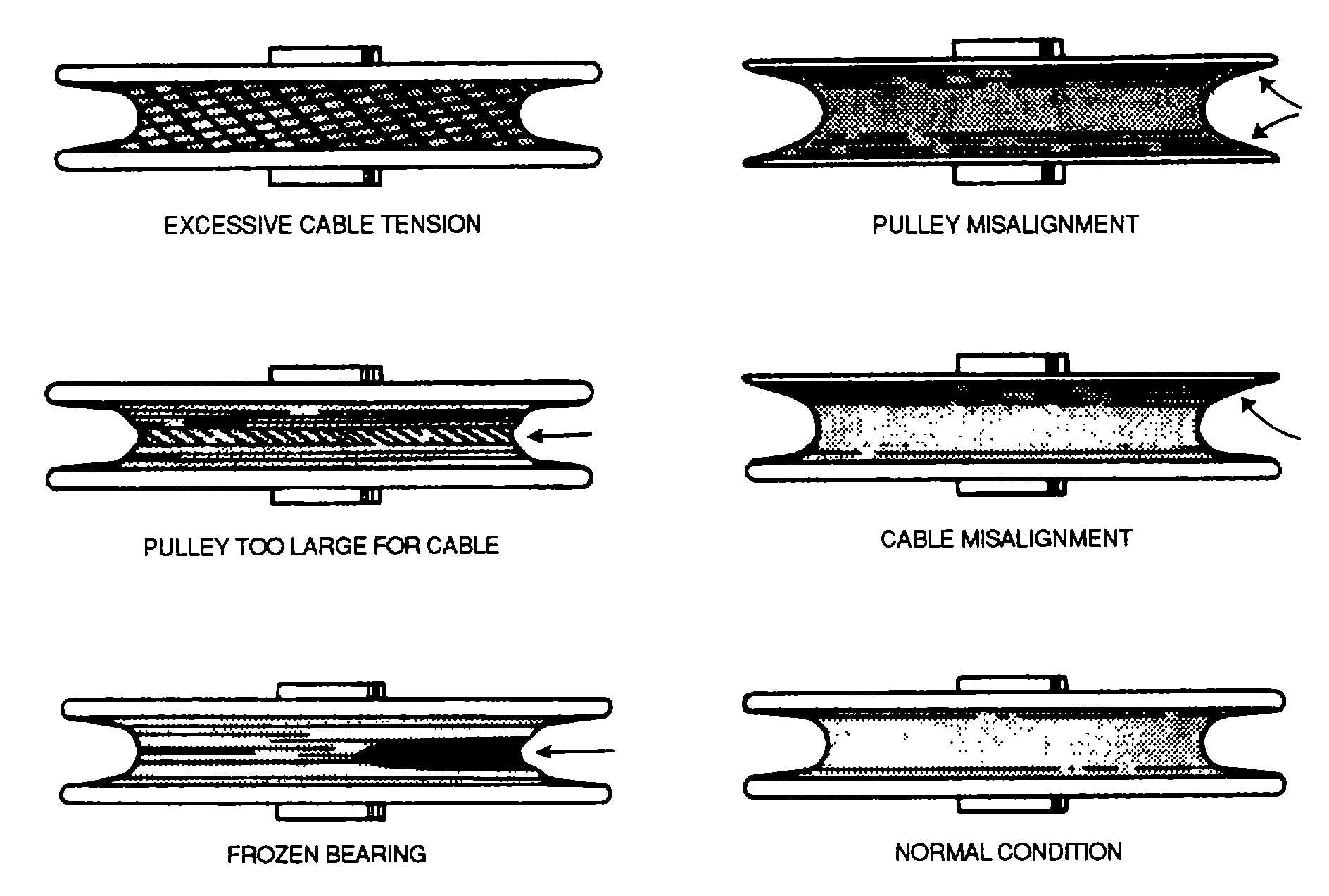

Figure 9-28. Pulley Wear Patterns

NOTE

It is good practice to rotate the pulley

90 degrees while inspecting, so as to

relocate the used area to another

position and thereby prolong the life

of the pulley

(5)

Control rods. Control rod assemblies

are used as links in mechanical systems to allow remote

operation and adjustment of components. Push-pull

linkage is designed and constructed so that both

torsional and compression forces will be transmitted to

the component being operated. Two common types of

push-pull linkage are the control tube and the control

rod. Control tubes, as shown in figure 9-29, consist of a

metal tube, usually made of steel or an aluminum alloy,

and two rod ends. One rod end is attached to each end

of the metal tube, which may be swaged, expanded, or

reamed at the ends to engage the rod ends. The rod

ends are welded or riveted to the tube.

NOTE

Operation or adjustment of some

accessories

or

flight

controls

requires a rotating motion which

often is accomplished by means of

torque tubes. To effect changes in

direction

of

the

torque

tube,

universal joints are required The

most common are MS20270 and

MS20271, which are attached to the

tube by bolts or rivets.

(a)

Inspection of control tubes. The

procedure which follows is common to all control tube

assemblies

Refer

to

the

applicable

manual

for

inspection of each particular component.

1 Check for bent or flattened

tube.

2 Check tube for nicks, dents,

gouges, scores or scratches, corrosion, and cracks.

9-26