TM 1-1500-204-23-1

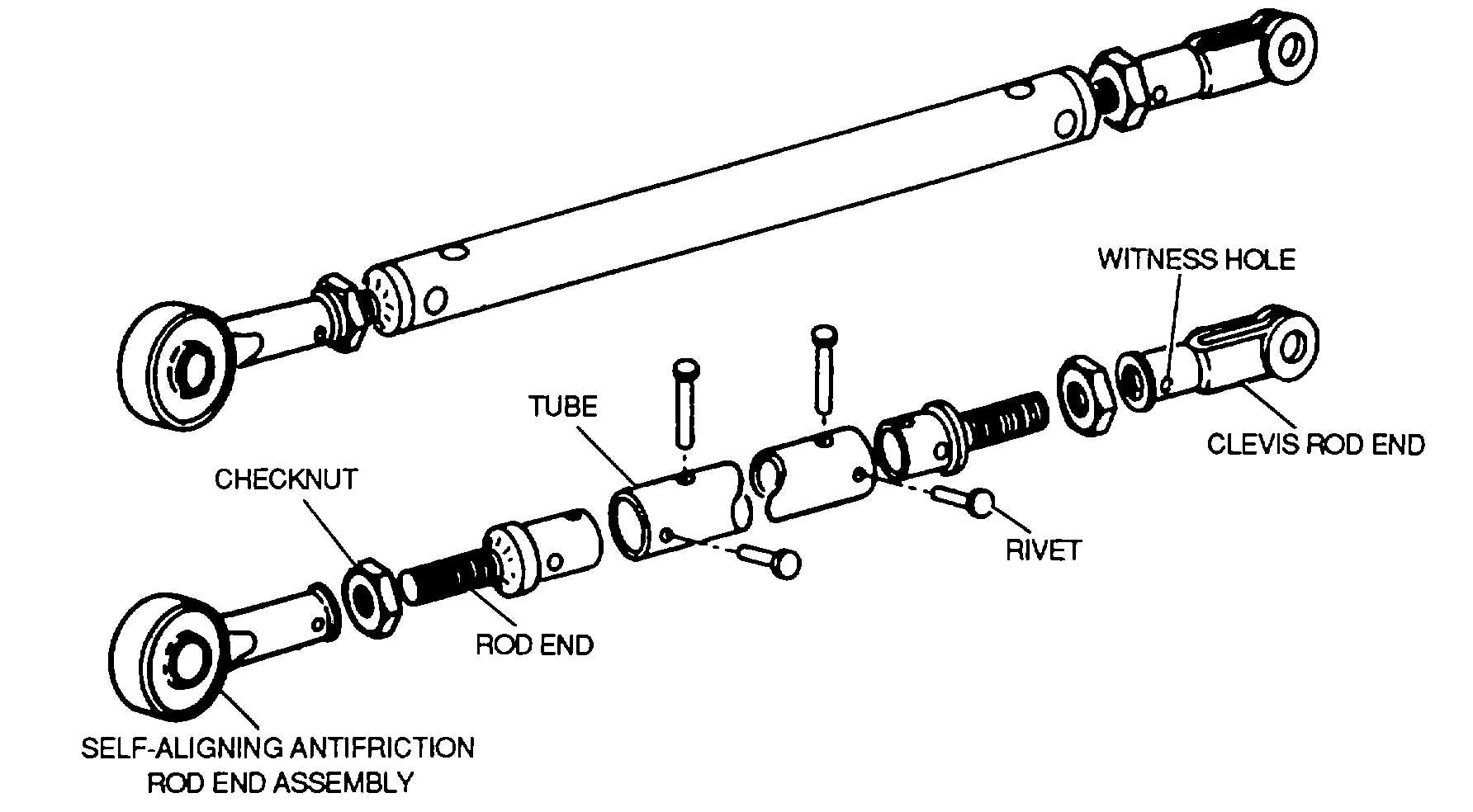

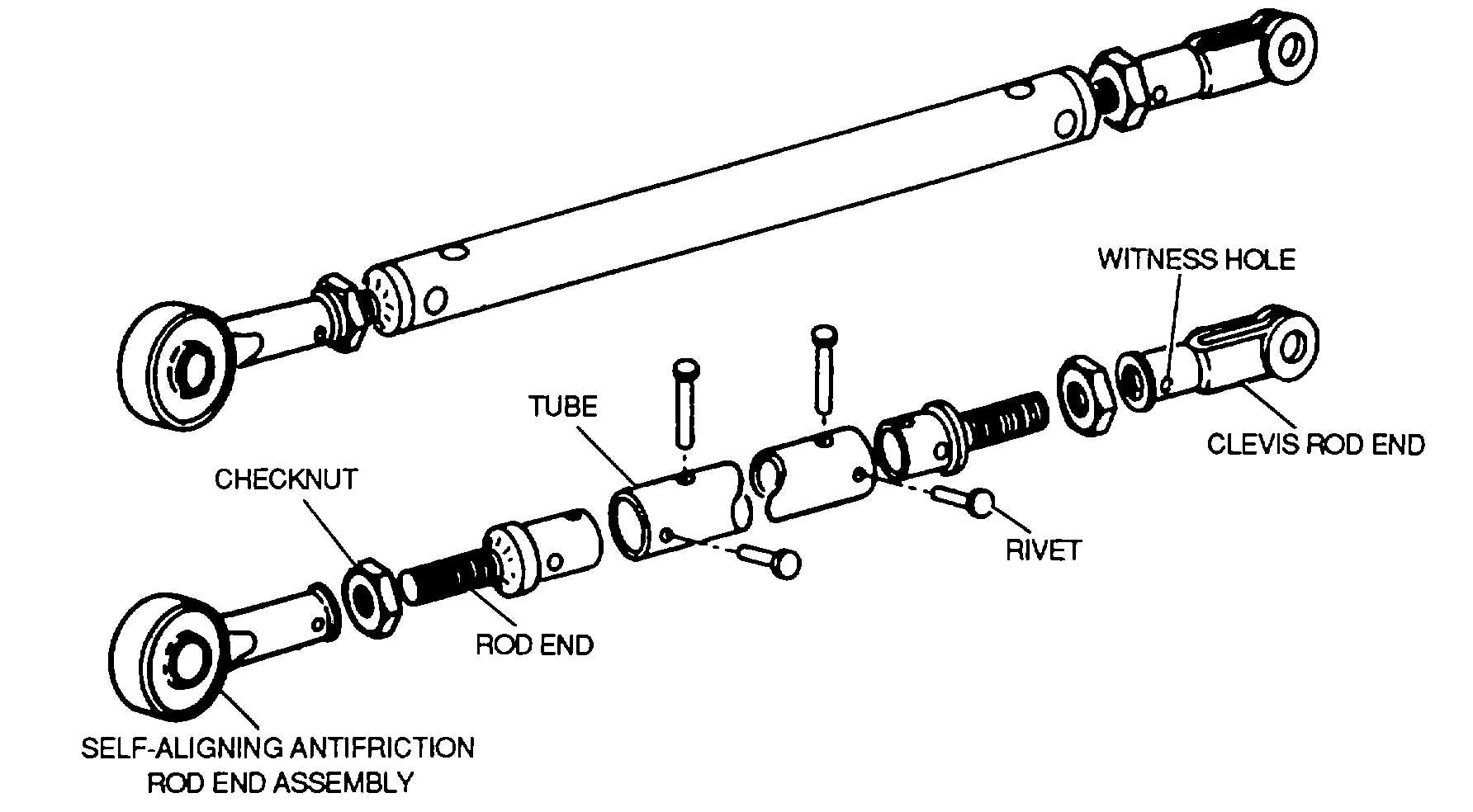

Figure 9-29. Control Tube Assembly

NOTE

If in doubt as to presence of cracks

in tube, strip the paint and make a

magnetic-particle

or

fluorescent-

penetrant inspection.

3 Check rod ends for security

(loose rivets), cracks or breaks, and damaged threaded

portions.

(b)

Repair of control tubes. Control

tubes can be repaired by methods similar to those used

on structural members. When repairing a control tube,

a perfect straightness must be obtained to preserve the

full strength of the tube. Sleeve reinforcements may be

added to steel tubes with a scarfed or fishmouth cut and

then welded in place. Aluminum alloy tubes can be

repaired in the same manner, using rivets for

attachment. If possible, the tube should be replaced

and the terminals salvaged. AN490 threaded rod ends

should be replaced because of difficulty in picking up

the original rivet holes.

NOTE

Do not attempt tube repair if center

one-third of assembly is damaged.

When replacing rod ends that are

riveted to control tube, rotate tube 90

degrees and redrill prior to riveting in

emergency,

repair

tubular

type

control rod by inserting a scarfed or

fishmouth sleeve reinforcement.

(c)

Installation of control tubes.

Install control tube assembly and rod ends as a unit, and

make adjustments at time of installation. Consult

applicable aircraft manual for proper dimensions and

settings. The following are general procedures:

1

Install

checknut

on

tube

assembly or threaded end of rod, and attach rod end to

assembly.

2 Adjust rod end to obtain

correct length of tube assembly Tighten checknut

against rod end to prevent its coming loose.

9-27