TM 1-1500-204-23-9

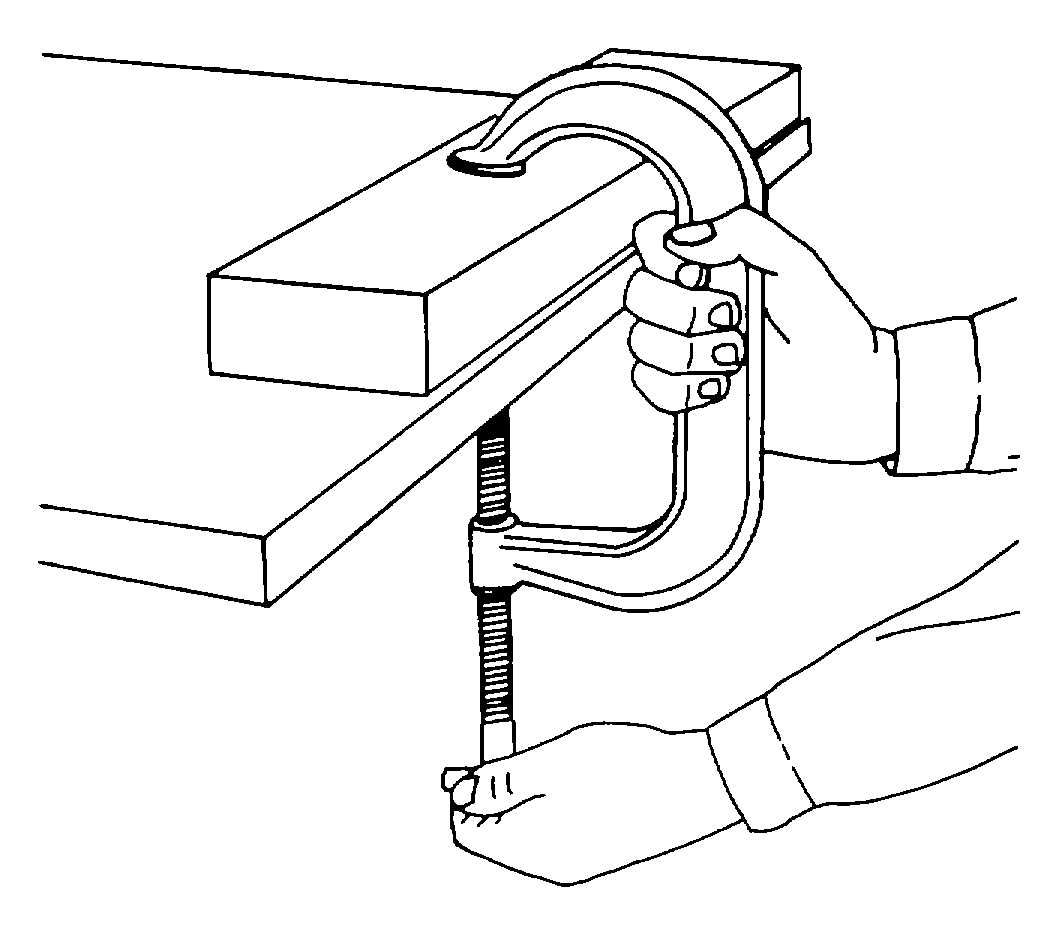

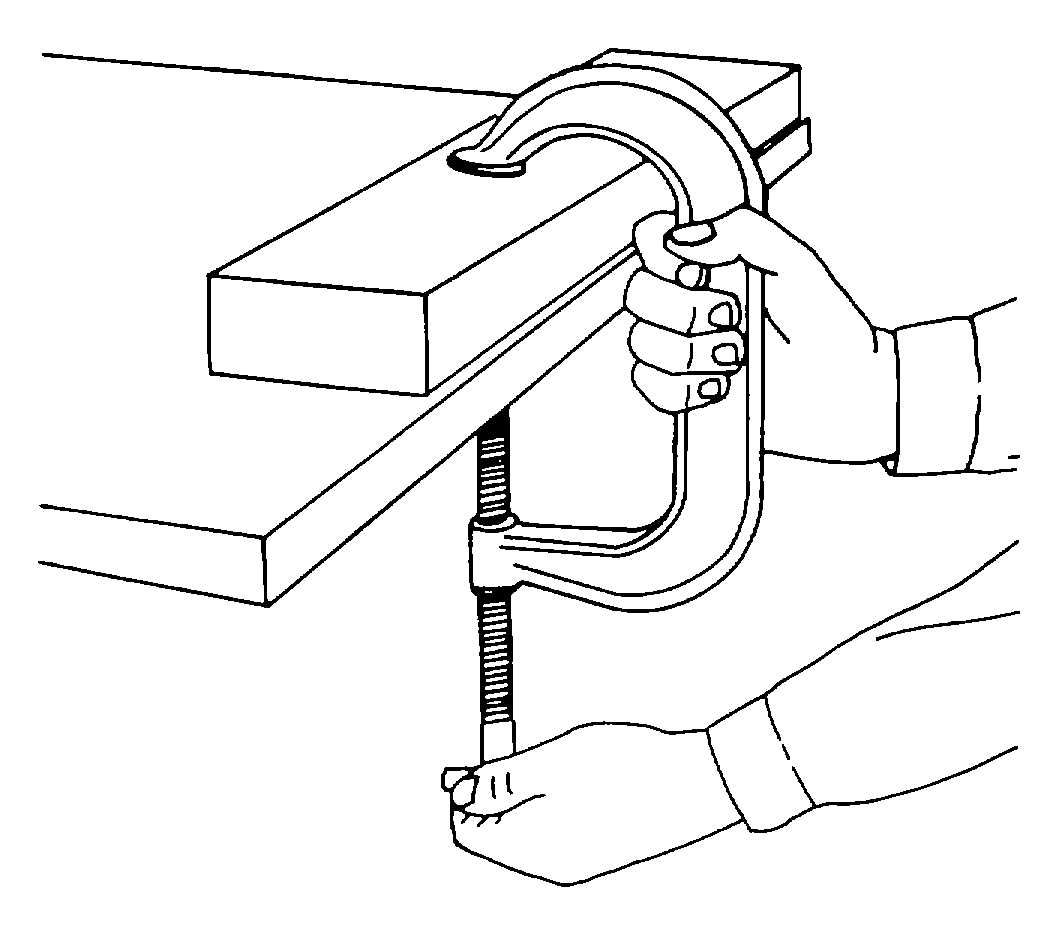

Figure 4-56. Using Carriage Clamp

CAUTION

Do not use wrenches or bars to tighten

clamps. Excessive pressure will result

in damage to the item being clamped.

(f)

Tighten the clamp against the surface.

(2)

Care. Observe the following practices for the

care and upkeep of C-clamps:

(a)

Clean threads and swivel with a rag, and

lubricate with a light coat of oil.

(b)

Store on a rack, on pins, or in a tool box.

(c)

For long storage periods, apply a rust-

preventive compound.

4-9. Cold Chisels. A chisel is a tool having a cutting

edge at the end of a metal blade and is used in

dressing, shaping, and working metal. The cold chisel

derives its name from the fact that it can be used to cut

metal that has not first been softened by heating. It is

usually made of carbon steel with a tempered cutting

edge.

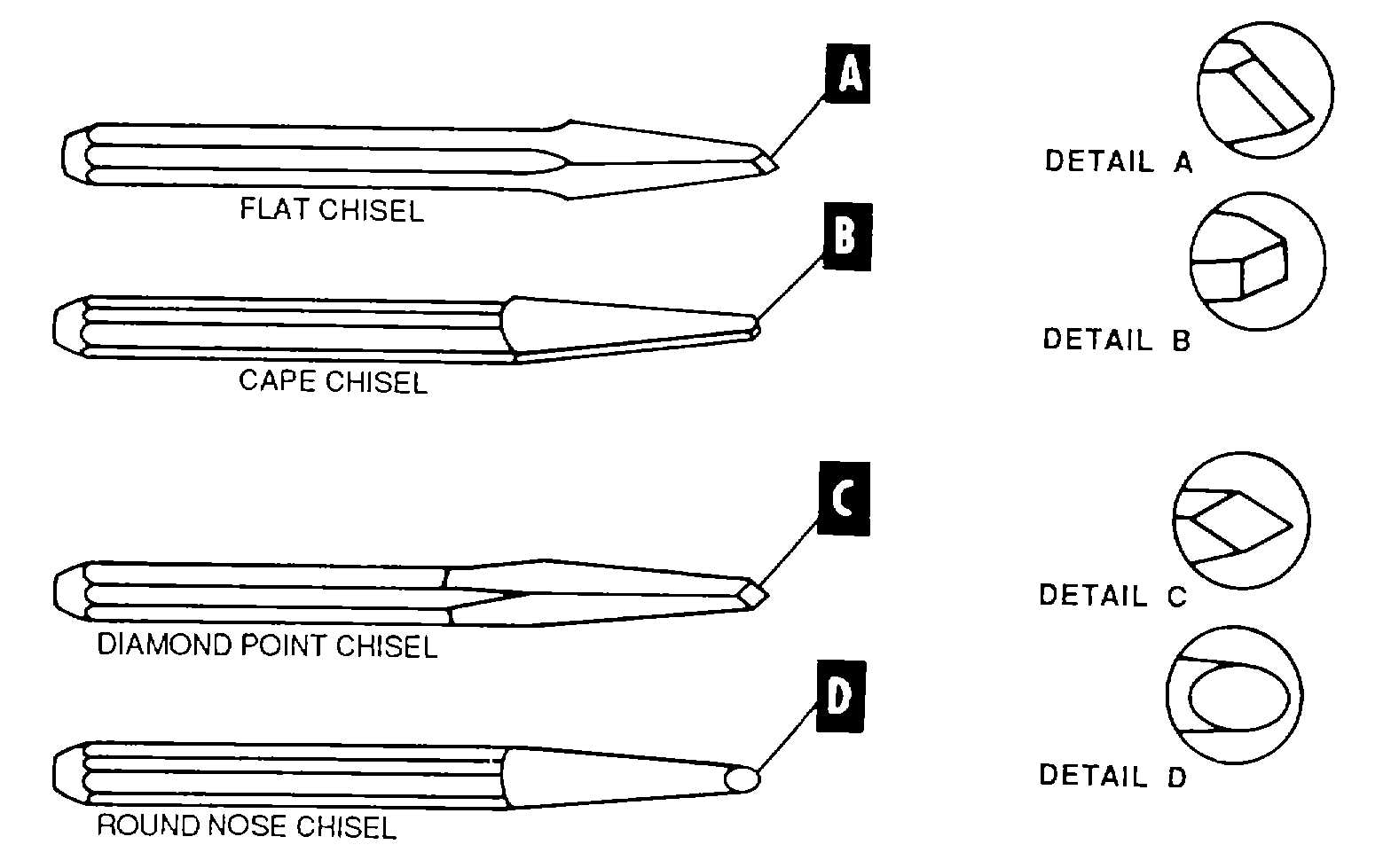

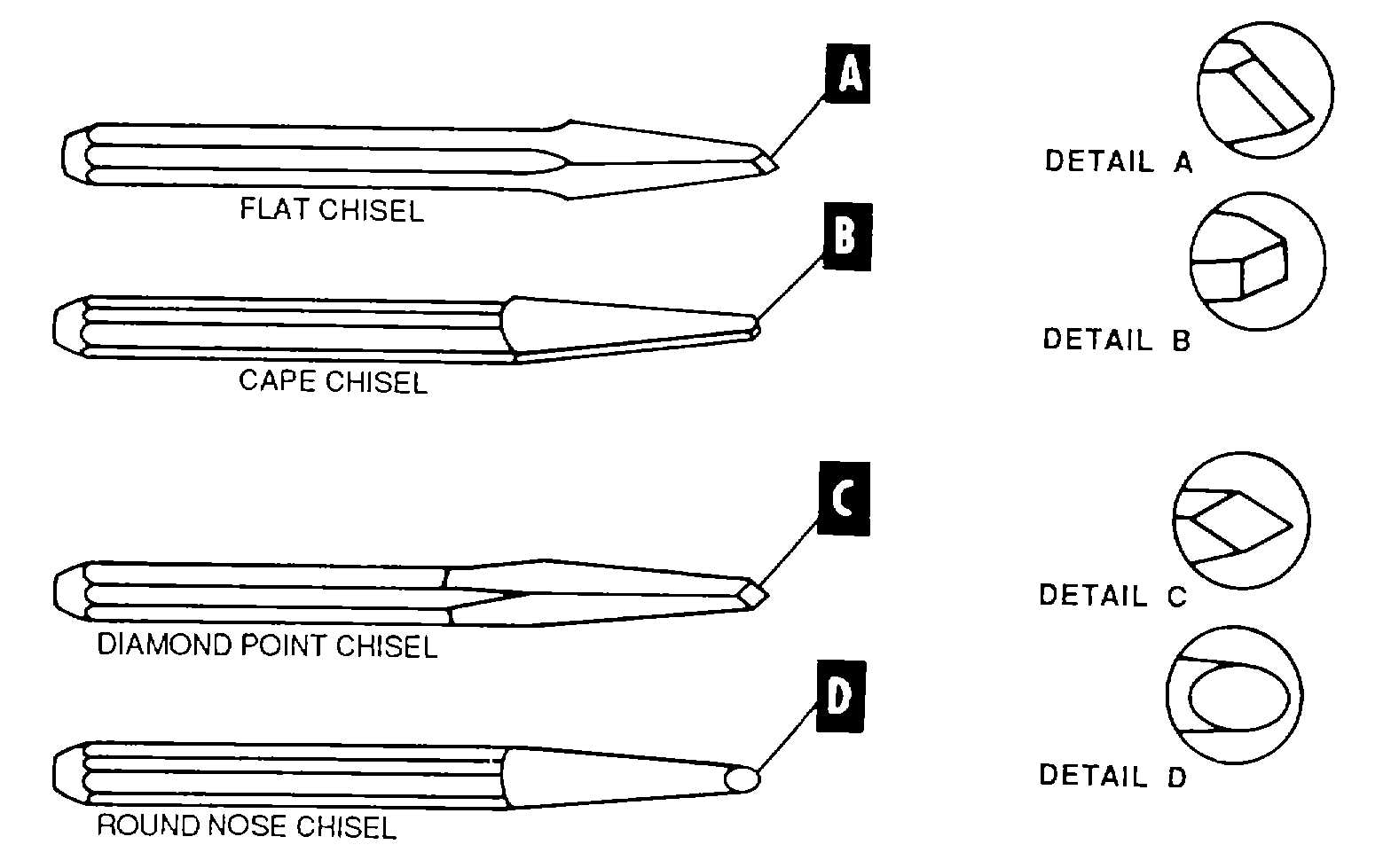

a.

Types. The most common types of cold chisel

are the flat, cape, roundnose, and diamond types,

shown in figure 4-57.

(1)

Flat chisel. The flat chisel is used to split

nuts, chip castings, and cut rivets and thin metal sheets.

(2)

Cape chisel. The cape chisel is used for

special jobs like cutting keyways, narrow grooves, and

square

corners.

Figure 4-57. Chisels

4-20