TM 1-1500-204-23-9

figure 4-68. They are used to file acute internal angles,

and to clear out square corners. Certain triangular files

are used to file saw teeth.

Figure 4-68. Triangular File

(b)

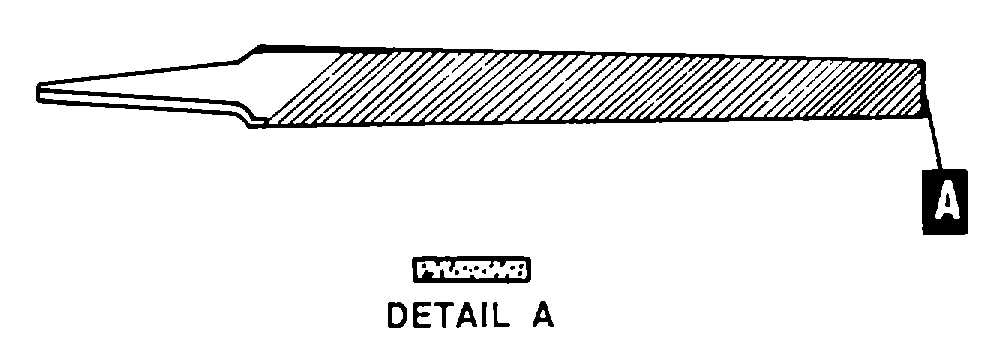

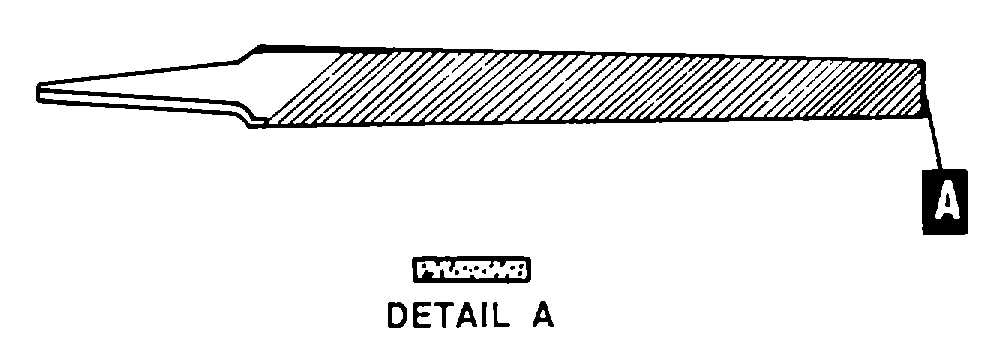

Mill files. Mill files are tapered in both

width and thickness. One edge has no teeth and is

known as a safe edge. Mill files, like the one shown in

figure 4-69, are used for smoothing lathe work, draw

filing, and other precision work. They are always

singlecut.

Figure 4-69. Mill File

(c)

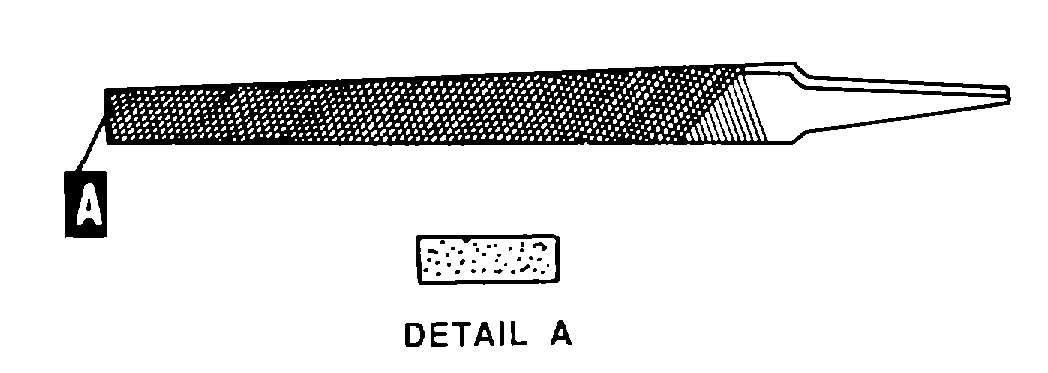

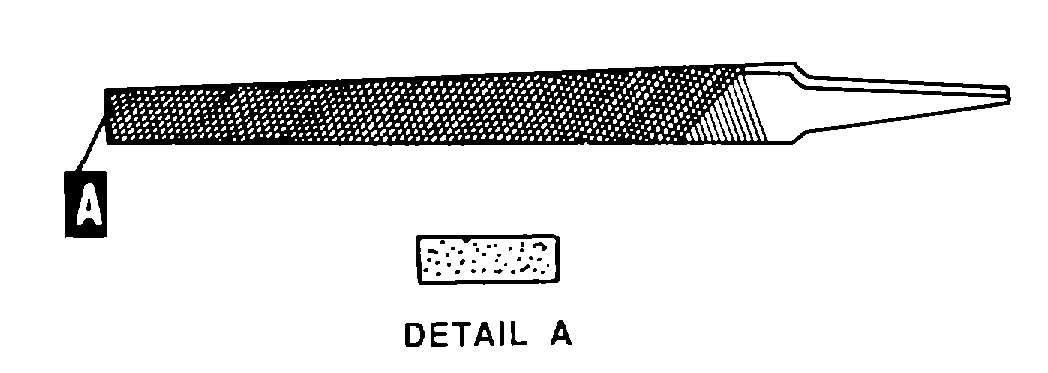

Flat files. Flat files, shown in figure 4-70,

are general-purpose files and may be either single or

double-cut. They are tapered in width and thickness.

Double-cut files are usually used for rough work, and

single-cut, smooth files are used for finish work.

(d)

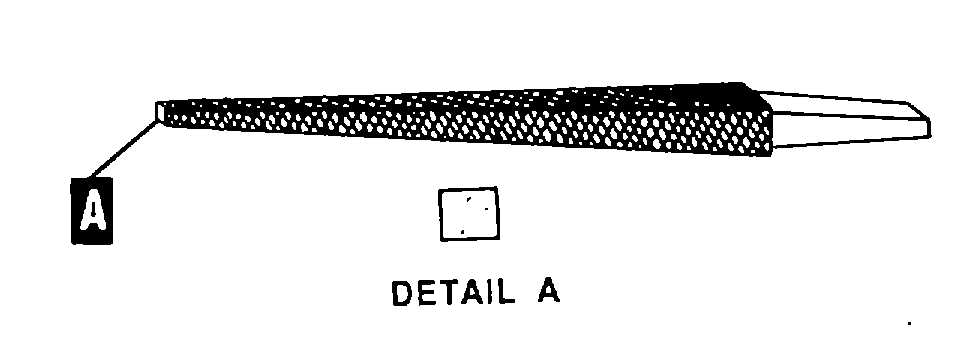

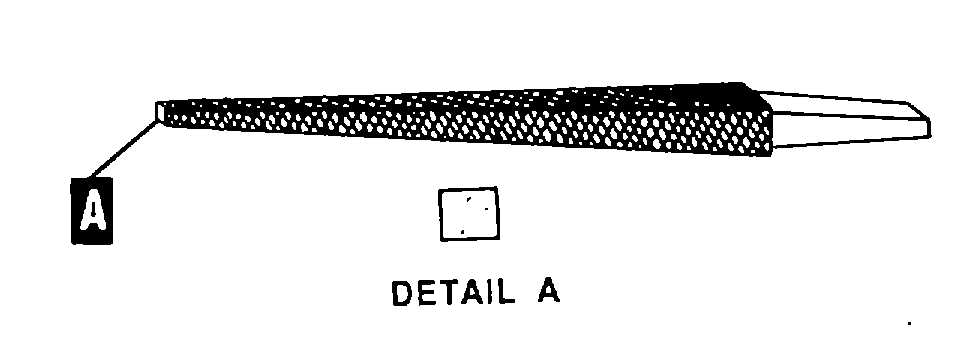

Square files. Square files, shown in figure

4-71, are tapered on all four sides and are used to

enlarge rectangular holes and slots.

(e)

Round files. Round files serve the same

purpose for round openings. Atypical round file is

shown in figure 4-72. Small round files are often called

rattail files.

(f)

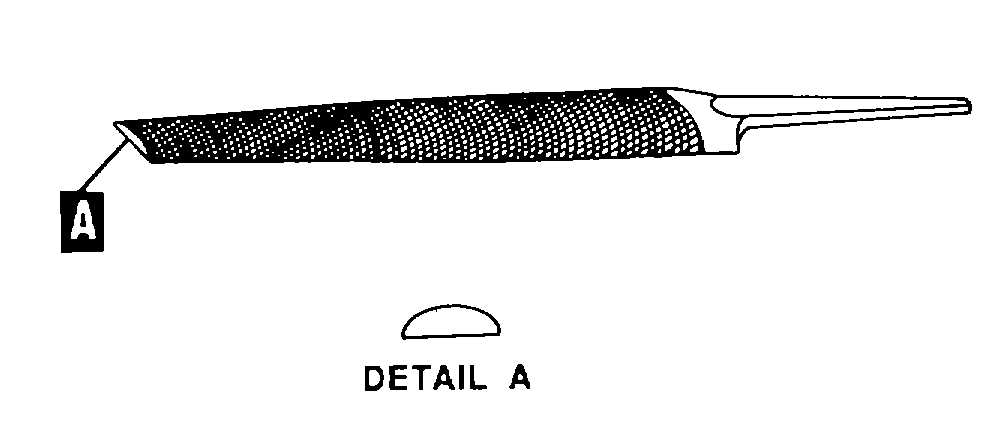

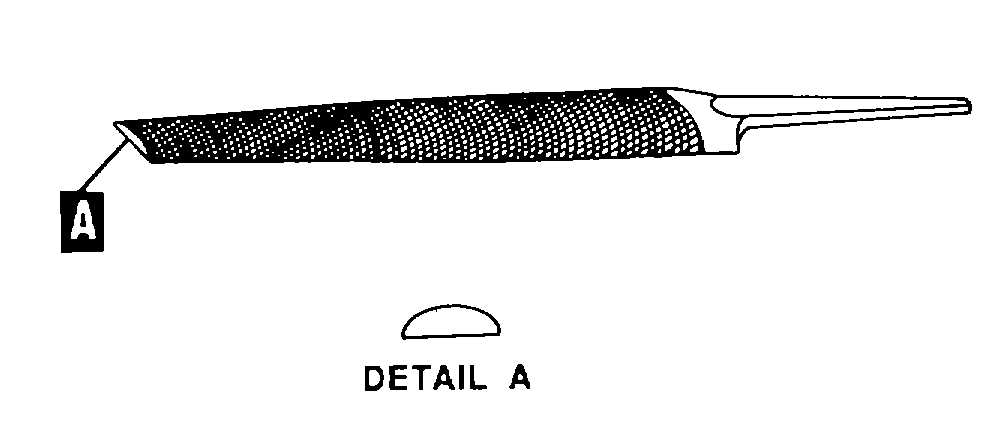

Half-round file. The half-round file is a

general purpose tool. The rounded side is used on

curved surfaces, and the flat side is used on flat

surfaces. When filing an inside curve, use a file whose

curve most nearly matches the curve of the work. This

file is shown in figure 4-73.

Figure 4-70. Flat File

Figure 4-71. Square File

Figure 4-72. Round File

Figure 4-73. Half-Round File

(3)

Curved-tooth files. Curved-tooth files are

generally used on aluminum and sheet steel and on

both flat and curved surfaces. They are also used for

smooth, rapid work on bronze, lead, babbitt, zinc and

plastic. The teeth come standard-cut and smooth-cut.

This type of file is shown in figure 4-74.

b.

Safety. The following paragraphs discuss

several important safety considerations regarding the

use of files.

4-25