TM 1-1500-204-23-9

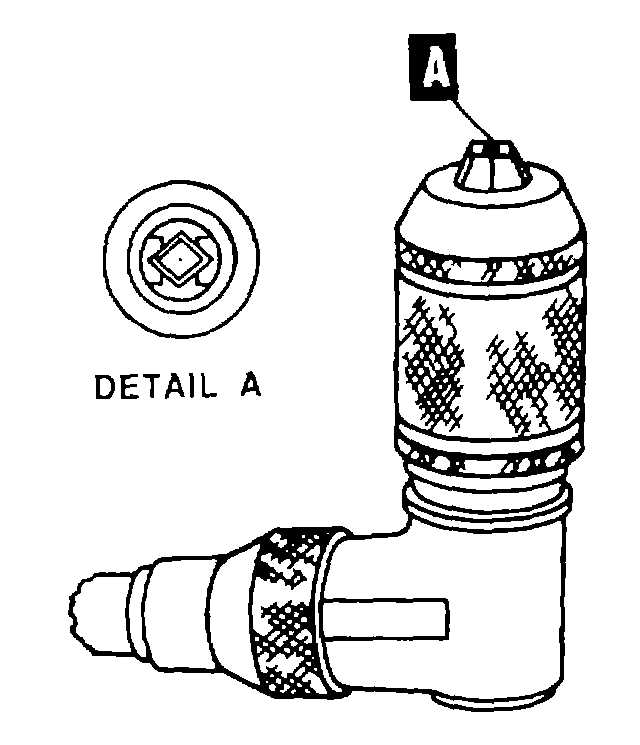

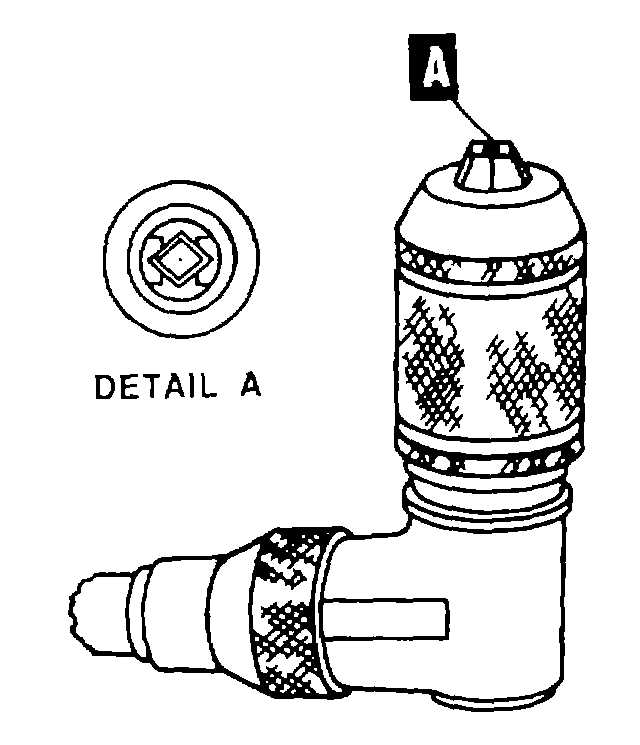

Figure 4-82. V-Grooves in Drill Jaws

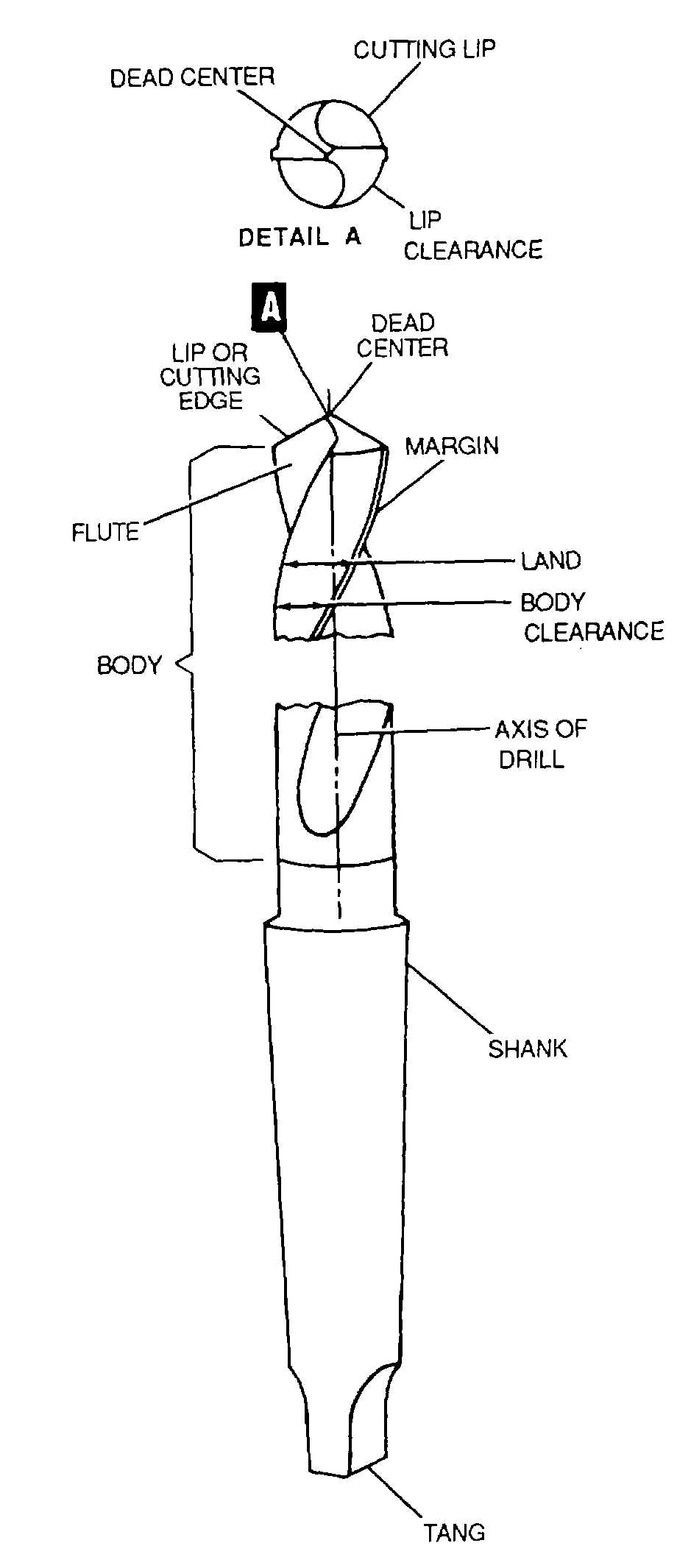

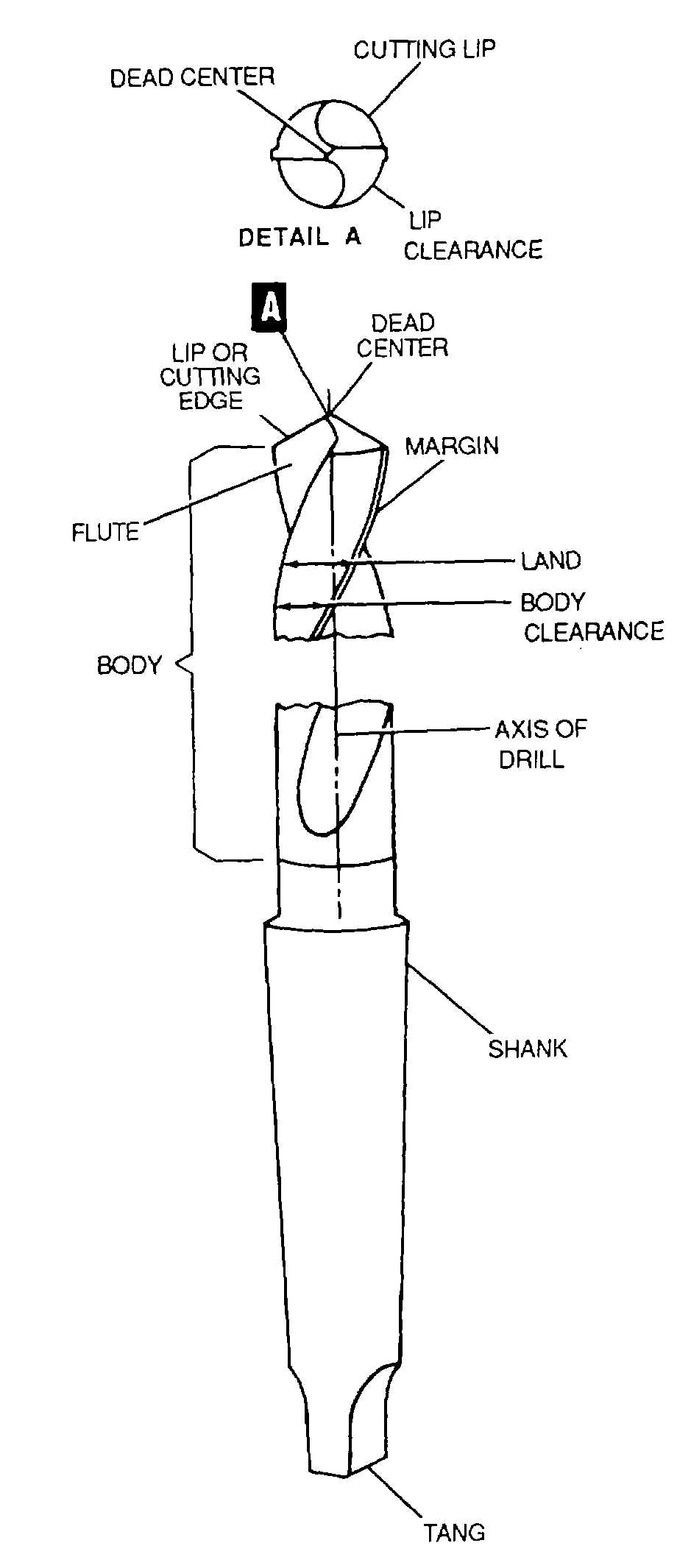

(1)

Lips. The lips are the parts which actually

do the cutting.

(2)

Flutes. The flutes allow the chips to

escape, give the correct rake to the lips or cutting

edges, and when it is necessary to use a lubricant, they

allow the lubricant to reach the cutting edges.

(3)

Body. The body of the drill is ground

away slightly, except at the margin, to reduce the friction

of the drill as it rotates.

b.

Sizes. The letter, number, fractional, and

decimal sizes of drill bits are shown in table 4-2.

c.

Use. The following paragraphs outline the

procedures for laying out and drilling holes.

(1)

Laying out. When laying out work, mark

hole locations as follows:

NOTE

Do not hit the center punch too hard

because it will dent the surrounding

metal. Place a bucking bar behind

the metal to prevent denting.

(a)

Locate the exact center of the hole to be

drilled and mark with a prick punch.

(b)

Enlarge the prick punch mark with acenter

punch so that the point of the drill can seat properly.

This is shown in figure 4-84.

(2)

Drilling. To drill the item, proceed as

follows:

(a)

Place the drill in the center-punched

mark. When using a powerdrill, rotate the bit a few turns

before starting the motor.

Figure 4-83. Typical Drill Bit

4-30