TM 1-1500-204-23-9

is generally the most common of the hand drills used in

Army aircraft maintenance.

b.

Use. The following paragraphs describe the

techniques for using hand drills.

(1)

Placing bit in chuck. To place the drill bit

in the chuck, proceed as follows:

(a)

Hold the shell of the chuck while turning

the handle to open the jaws.

(b)

When the jaws are apart far enough to

accept the drill bit, insert it until the end

seats in the bottom of the chuck.

(c)

Tighten the chuck by turning the handle to

close the jaws. Ensure that the bit is

firmly

seated

within

the

V-grooves

machined into the jaws, as shown in figure

4-82.

(2)

Breast drill. Proceed as follows:

(a)

Turn the crank handle with one hand while

holding the side handle with the other

hand.

(b)

Apply feed pressure by leaning against

the breast plate.

(3)

Drilling. When drilling with the hand drill,

operate the crank with one hand, and with the other

hand guide the drill by holding the handle on the end of

the drill.

c.

Care. Observe the following practices for the

care and upkeep of hand drills:

(1)

Apply a light coat of oil to all metal

surfaces.

(2)

With a rag, clean gear teeth of dirt, wood,

and metal shavings.

(3)

Hang drills on a rack in a dry location.

4-13. Drill Bits. A drill bit is a pointed tool that is

rotated to cut holes in material. It is made of carbon

steel or harder alloy steels, depending upon the type of

work required.

a.

Description. A typical drill bit and its parts are

shown in figure 4-83. Some of these parts are

explained in the following paragraphs.

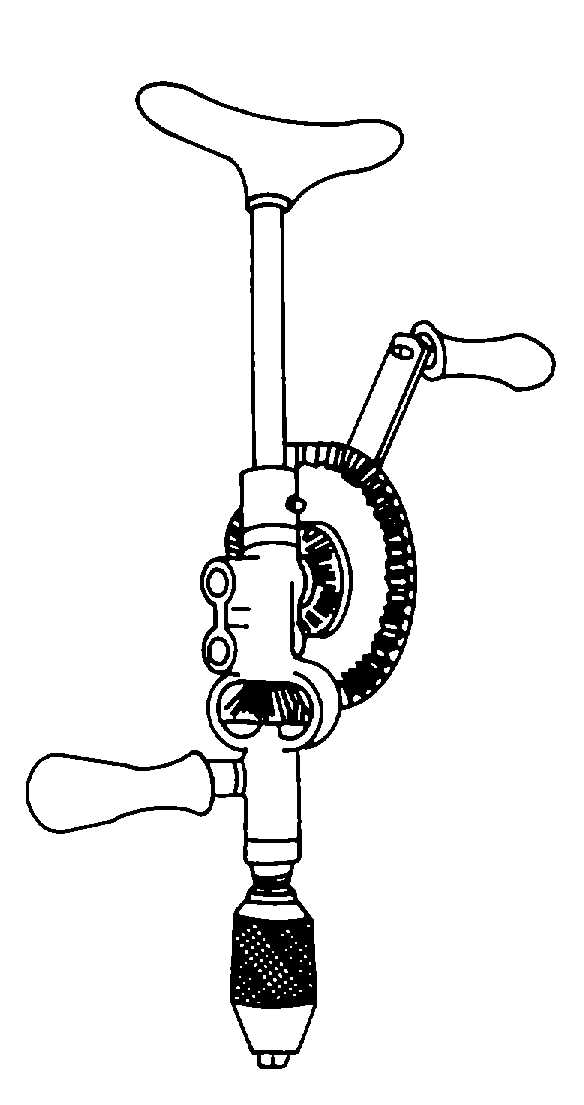

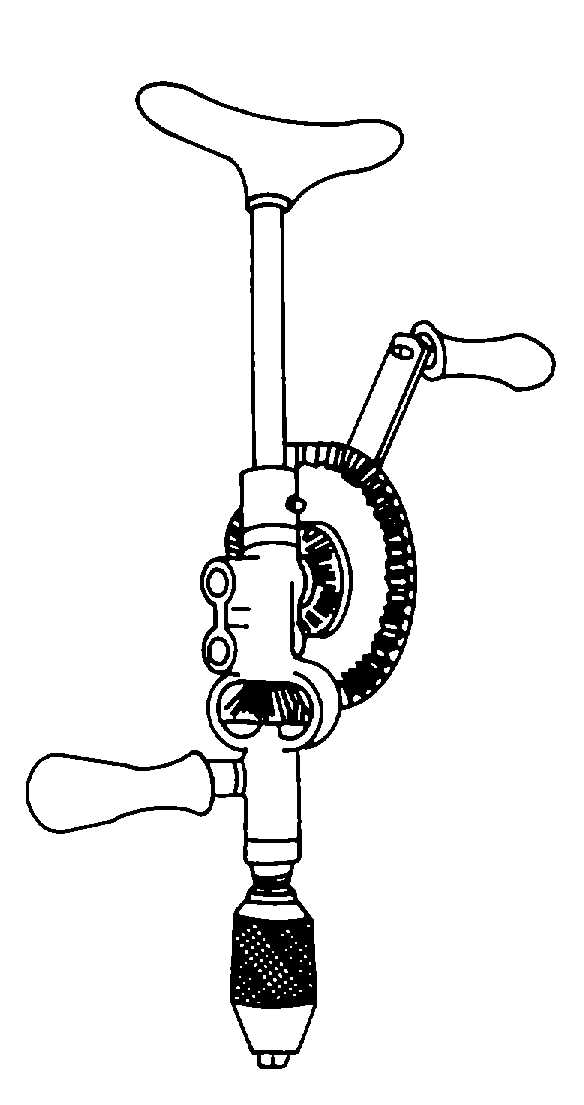

Figure 4-80. Breast Drill

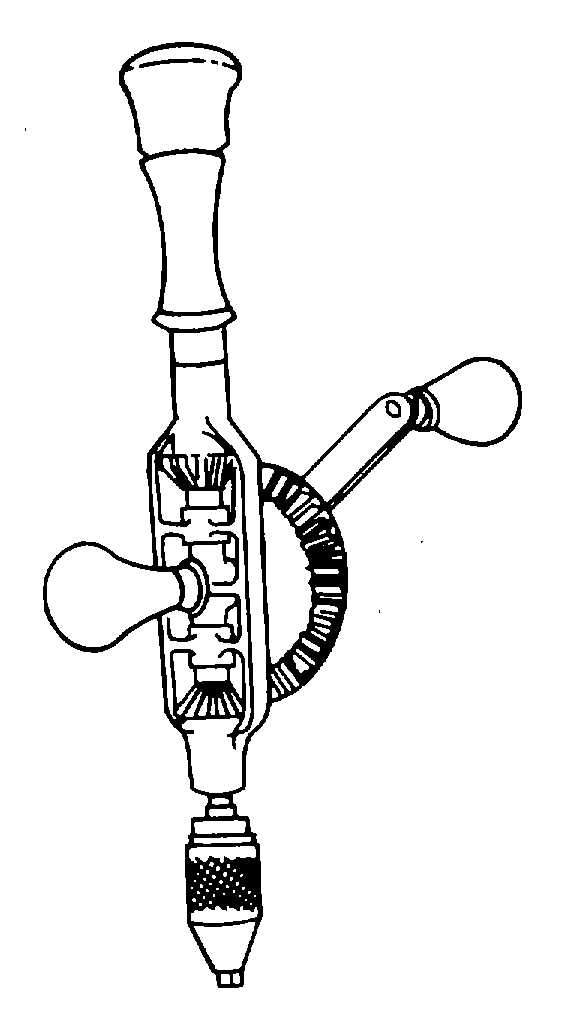

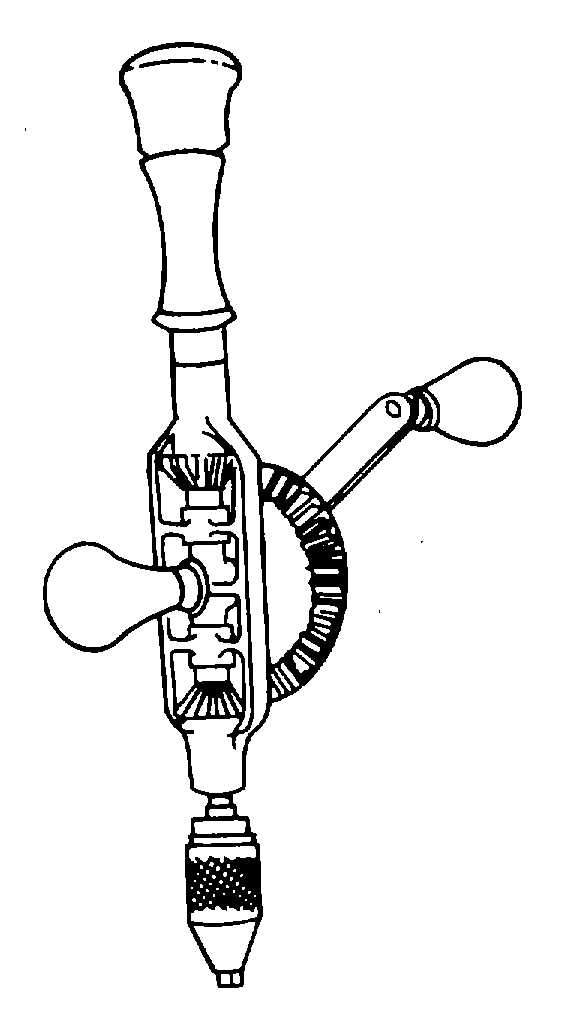

Figure 4-81. Hand Drill

4-29